A wear-resistant fan

A technology for fans and wear-resistant plates, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of reduced blade strength, increased cost, narrow space, etc., to shorten maintenance and replacement time, improve service life, and improve The effect of productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

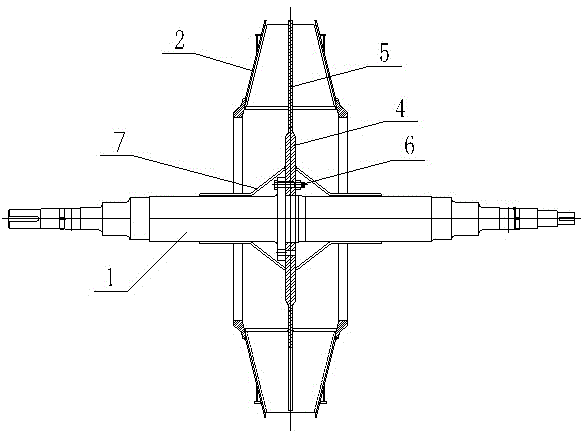

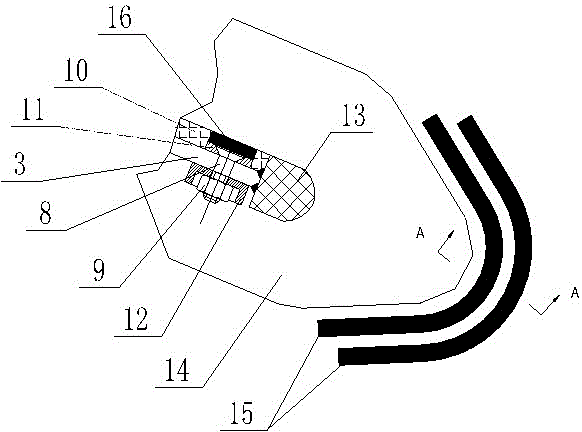

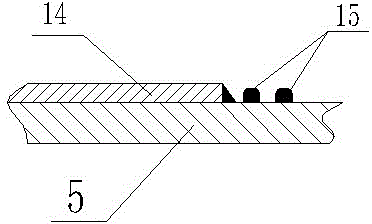

[0023] As shown in the figure, the wear-resistant fan of this embodiment includes a rotor main shaft 1, a wheel cover 2, and blades 3. The blades 3 are welded by an inner middle disk 4 and an outer middle disk 5. The rotor main shaft 1 is connected by connecting bolts. 6 is fixedly connected with the inner disc 4, the key is that the wear-resistant fan also includes a protective cover 7, one end of the protective cover 7 wraps the main shaft 1, and is welded with the main shaft 1, and the other end is welded with the inner disc 4, so that Cover the connecting bolt 6 in the space surrounded by the protective cover 7 , the main shaft 1 and the inner middle disc 4 .

[0024] Protective cover 7 can avoid the washing and wear of dust to connecting bolt 6 and main shaft 1. After protective cover 7 is worn, repair welding or replace it with a new one after all cutting off, because this position is located at the inlet of impeller, which is convenient for replacement and maintenance. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com