Surface seamless type bridge expansion joint

A technology for expansion joints and bridges, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as driving comfort and short life span of bridges, and achieve the effects of short construction period, convenient maintenance and repair of bridge deck, and weakening impact effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

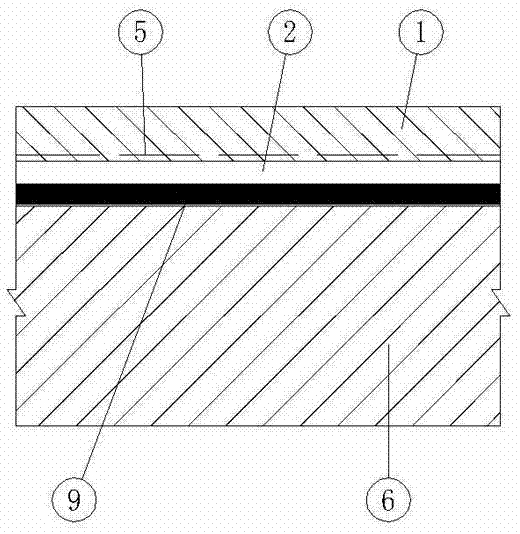

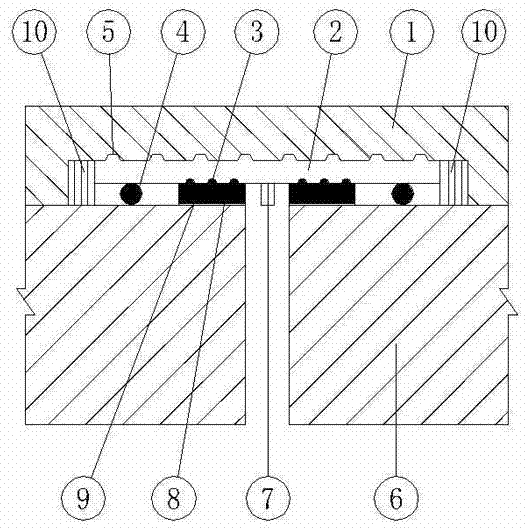

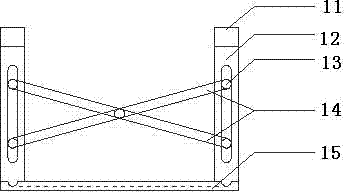

[0025] New bridge expansion joint structure: pre-embed the anchoring device 8 at the end of the main beam, connect and fix the sliding plate 9 and the anchoring device 8 on the surface of the main beam, the top surface of which is flush with the surface of the main beam, and install the bearing plate 2 above it , and apply lubricant in the lubricant groove 3, and install elastic deformation bodies 10 at both ends of the bearing plate 2. One end of the elastic deformation body 10 is fixedly connected with the bearing plate 2, and the other end should be fixedly connected with the connecting steel bars reserved for the main beam. After the installation is correct, pave the bridge deck pavement layer 1.

Embodiment 2

[0027] Replace the bridge expansion joint structure of the old bridge: connect the sliding plate 9 and the anchoring device 8 to the surface of the main beam 6, fix the sliding shaft 4 on the surface of the main beam 6, install the bearing plate 2 above it, and apply it to the lubricant groove 3 Lubricant, install the elastic deformation body 10 on both sides of the bearing plate 2, one end of the elastic deformation body 10 is fixedly connected with the bearing plate 2, and the other end should be fixedly connected with the connecting steel bar reserved for the main beam 6, after the above installation is correct, pave Bridge deck pavement layer 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com