A long-life oxygen-blowing metal hose

A metal hose, long-life technology, applied in the direction of pipe elements, pipes/pipe joints/pipes, expansion compensation devices for pipelines, etc. Easily damaged, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

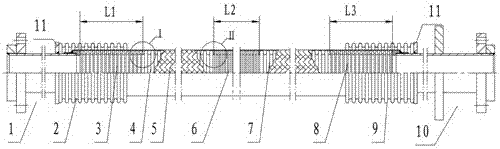

[0016] see figure 1 , the long-life oxygen-blowing metal hose of the present invention includes a bellows as a main part, and a first joint 1 and a second joint 10 are arranged at both ends of the bellows, and the outside of the bellows is coated to improve the pressure bearing capacity of the bellows And the metal mesh body 5 that constitutes protective effect to the bellows, the total length of the bellows is 12-16 meters.

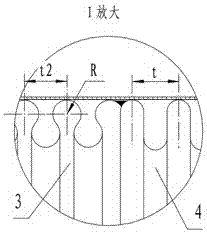

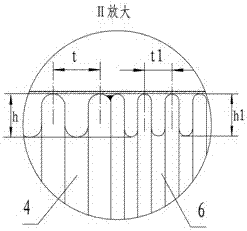

[0017] see Figure 1-Figure 3 , the main improvement of the present invention is reflected in the corrugated pipe. According to the use characteristics of the corrugated pipe, the corrugated pipe is designed as a five-stage structure, that is, the bellows are from left to right as the first pressure-resistant section 3 and the first transition section 4. 1. The highly flexible section 6, the second transition section 7 and the second pressure-resistant section 8 are connected by welding, and the nominal diameter of each section is D. Among them, the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com