Capacitor with standby capacitor

A technology of capacitors and circuits, applied in the field of capacitors, can solve problems such as time-consuming, increase safety hazards, fire or explosion, etc., and achieve the effects of saving maintenance and replacement time, ensuring normal operation, and short power-off time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

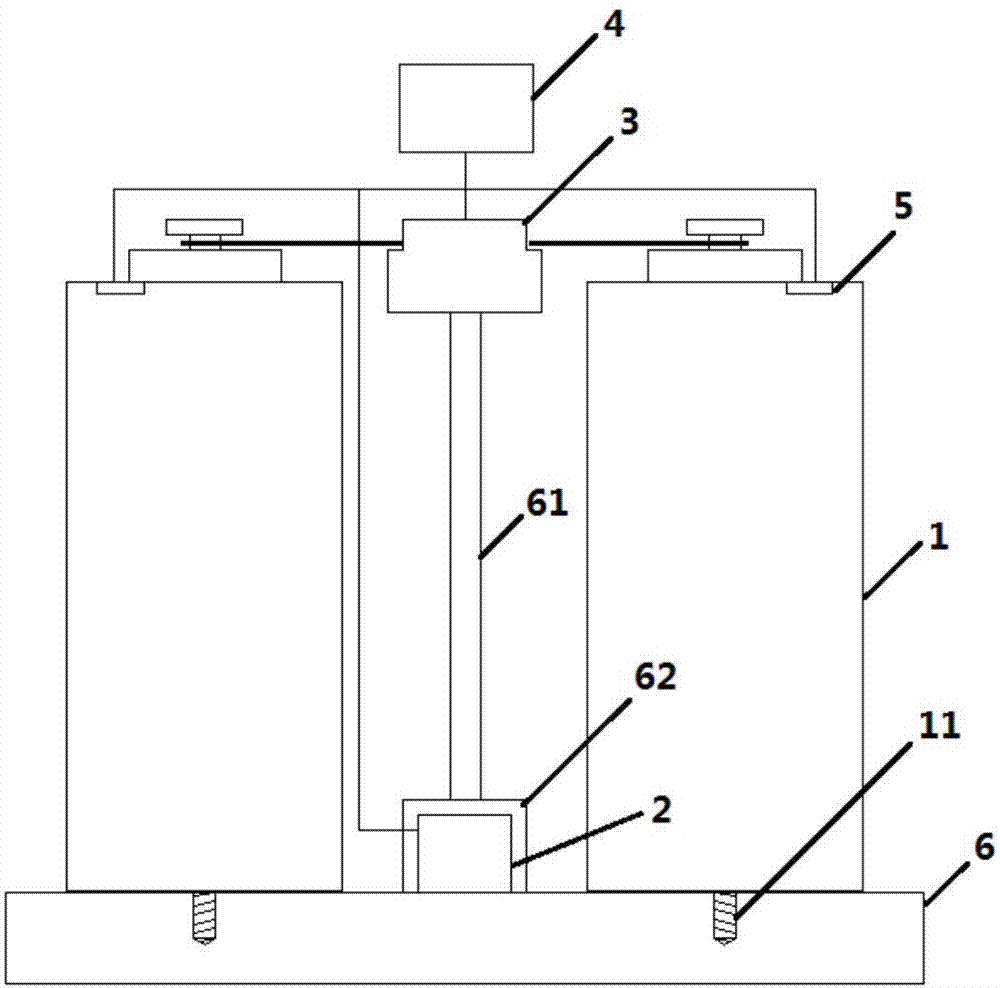

[0016] A capacitor with a backup capacitor, including a capacitor 1, a controller 2, a circuit switcher 3, a circuit breaker 4, and a pressure sensor 5, the number of the capacitors 2 is two, and the two capacitors 2 are installed side by side on the same base 6 Above, the two sets of terminals of the circuit switcher 3 are respectively connected to the terminals of the two capacitors 2 one by one. After the circuit breaker 4 is connected in series with the circuit switcher 3, the circuit breaker 4 is connected to the main circuit, and the controller 2 is connected to The circuit breaker 4 is connected to the circuit switcher 3, and the number of the pressure sensors 5 is two, and the two pressure sensors 5 are respectively arranged inside the two capacitors 2, and the pressure sensors 5 are connected to the controller 2 through signal lines.

[0017] Further, a pressure sensor 5 is arranged inside the capacitor 1, and the pressure sensor 5 is fixed on the bottom surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com