Ball cage type cardan shaft for screw drilling tool

A screw drilling tool and cage-type technology, which is applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of reducing the overall service life of the screw drilling tool, poor sealing performance of the sealing structure, and low drilling efficiency, etc., to achieve shortening Maintenance and replacement time, excellent sealing performance, and the effect of improving drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

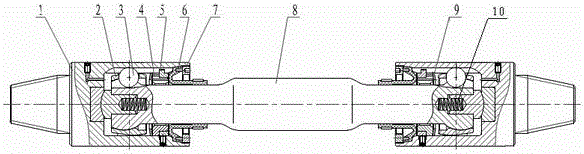

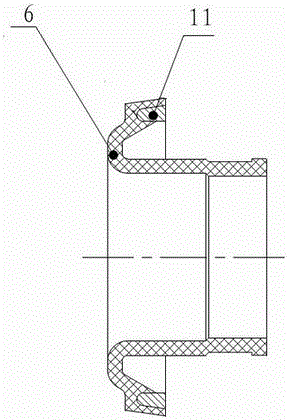

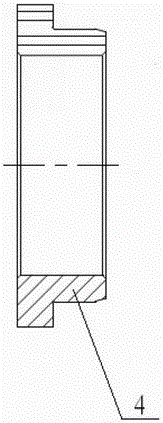

[0020] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, the outer sleeve joint 1 is respectively connected to the intermediate shaft 8 via the steel ball 3 in the cage 2. The end of the outer sleeve joint 1 is equipped with a sealing cover 6 which is made of cyanide nitrile butadiene rubber, and the sealing cover 6 has The steel frame 11 and the sealing cover 6 adopt an inwardly curved compression structure. The sealing cover 6 has high strength, high temperature resistance and high pressure resistance, and good flexibility. It can be normal in high temperature (180℃) and high pressure (7atm or 0.7MPa) environments Work, the sealing cover 6 and the outer sleeve joint 1 are conical surface compression fit, the sealing effect is reliable, and the universal joint shaft will not be worn sharply due to the intrusion of sand during the working process. The end of the sealing cover 6 is equipped with pressure The cover 7; the snap ring 5 and the safe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com