Bearing sealing structure and electric spindle with same

A bearing sealing and shaft core technology, applied in the direction of bearing components, shafts and bearings, engine sealing, etc., can solve the problems of leakage of the sealing structure, affecting the service life of the motorized spindle, reducing the bearing performance, etc., to achieve good sealing, enhanced waterproofing Dust, Enhanced Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

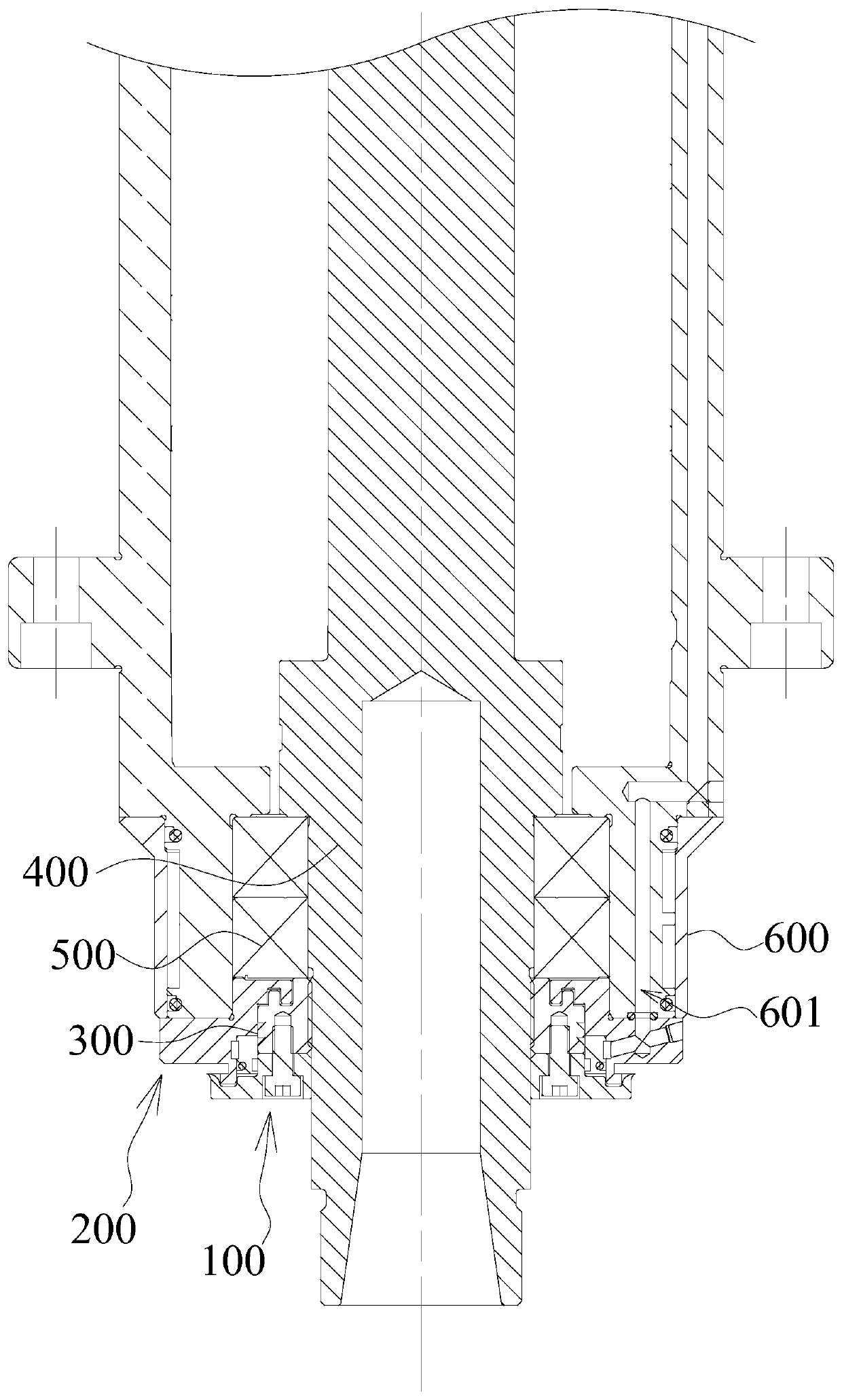

[0037] It should be noted that the bearing sealing structure of the present invention can not only be used in electric spindles to achieve sealing of bearings (for example, it can be used in electric spindles of horizontal machining centers), and can also be used in other shaft structures to achieve sealing.

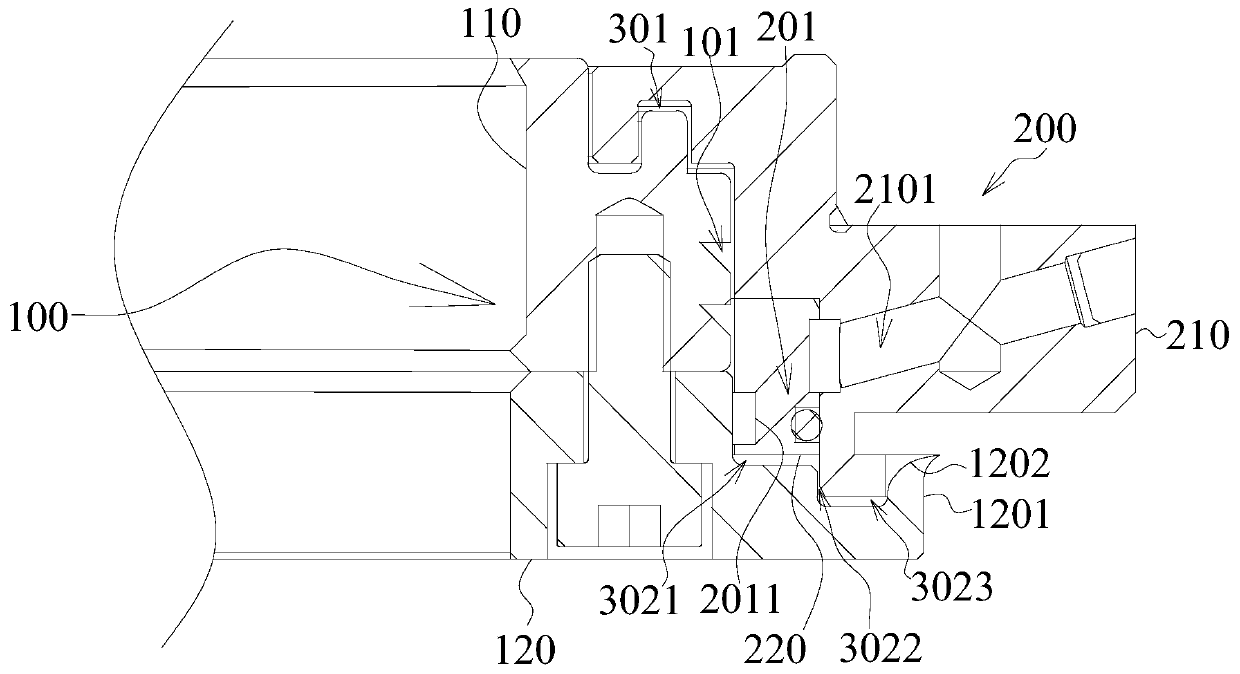

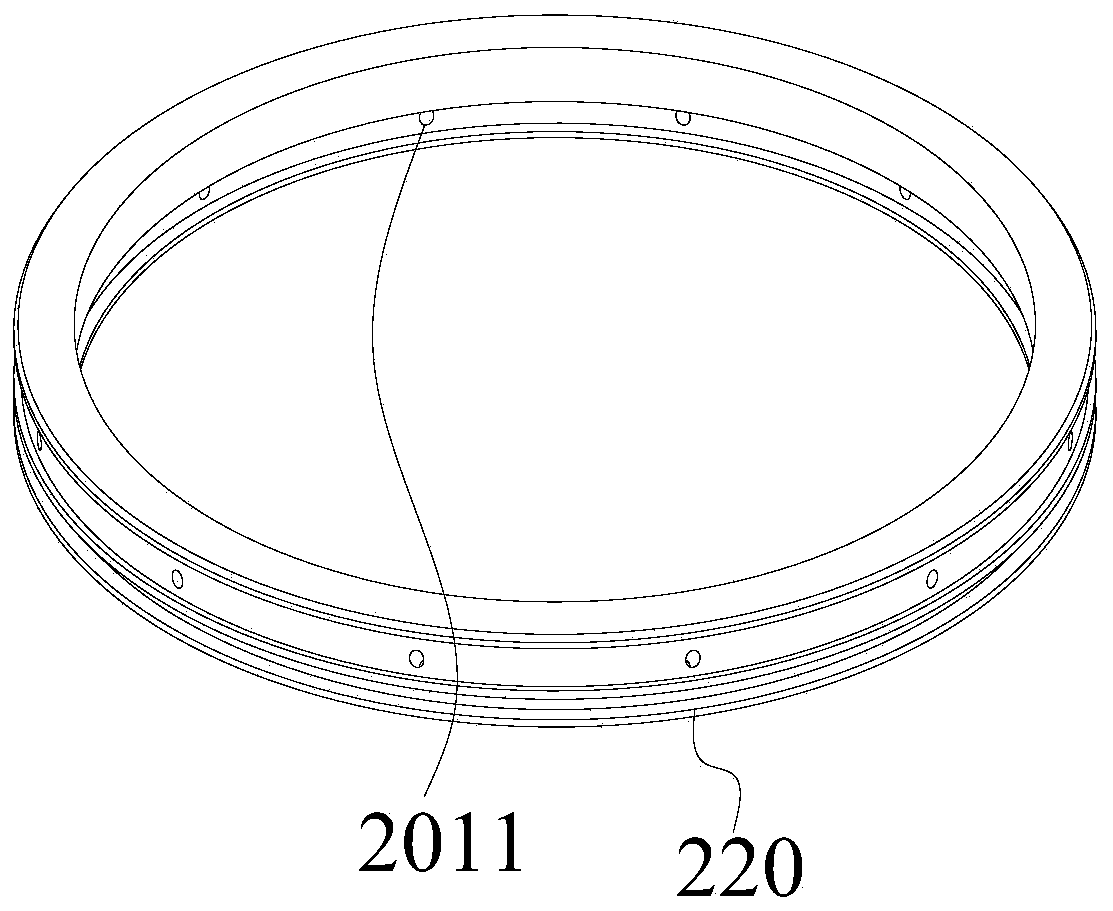

[0038] Such as Figure 1~5 As shown, this embodiment provides a bearing sealing structure, including a lower cover 200, a locking member 110 and a protective cover 120. The locking member 110 is connected with the protective cover 120 to form a rotating assembly 100. The rotating assembly 100 has an opposite first side and On the second side, th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap