A large-diameter annular magnetic levitation motor and its control method

A magnetic levitation and large-diameter technology, which is applied in the direction of electromechanical devices, electrical components, magnetic attraction or thrust holding devices, etc., can solve the problems of easy wear and fatigue, high maintenance costs, and low maintenance costs, achieving no mechanical wear, Low maintenance cost, low vibration and noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

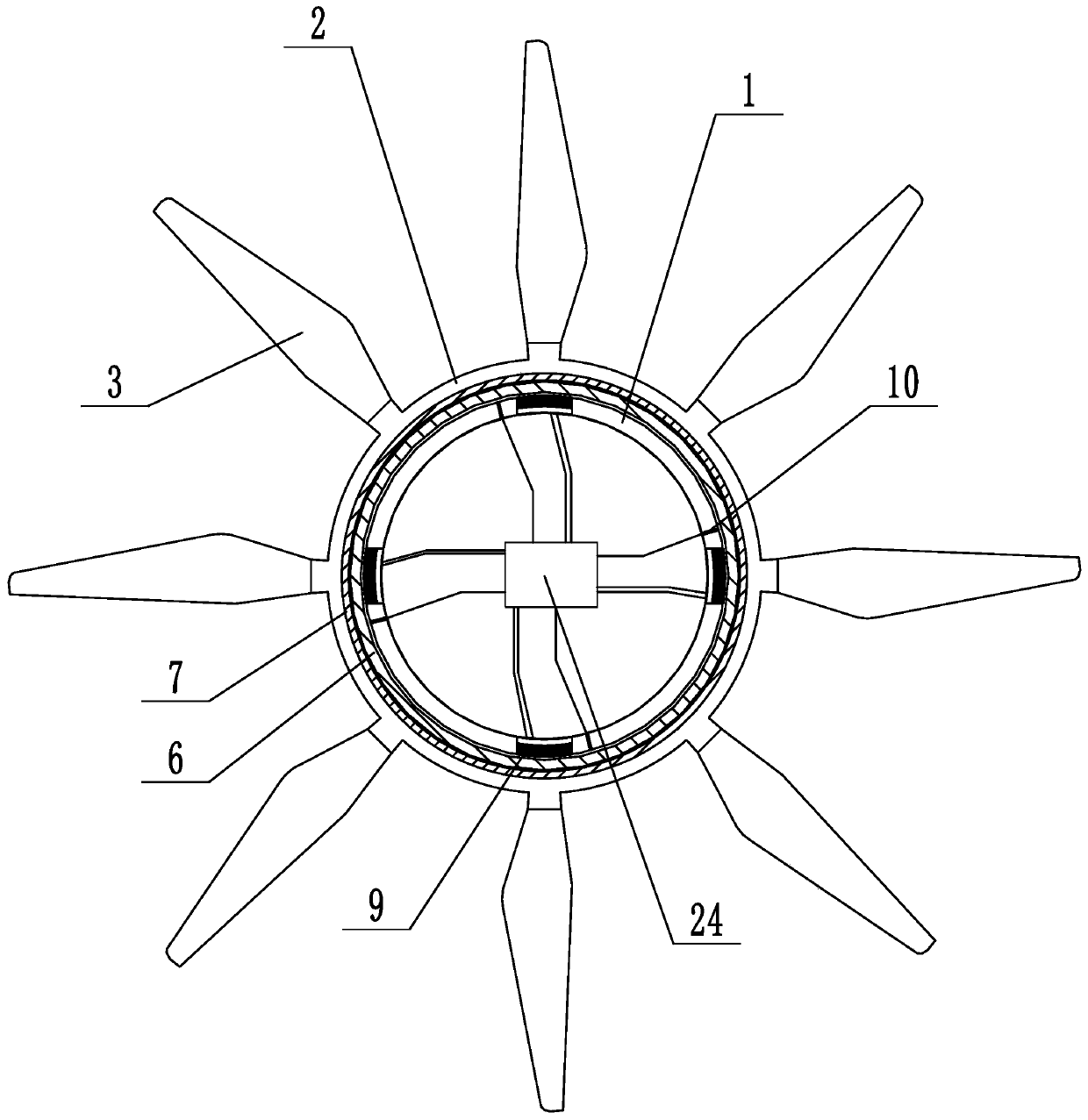

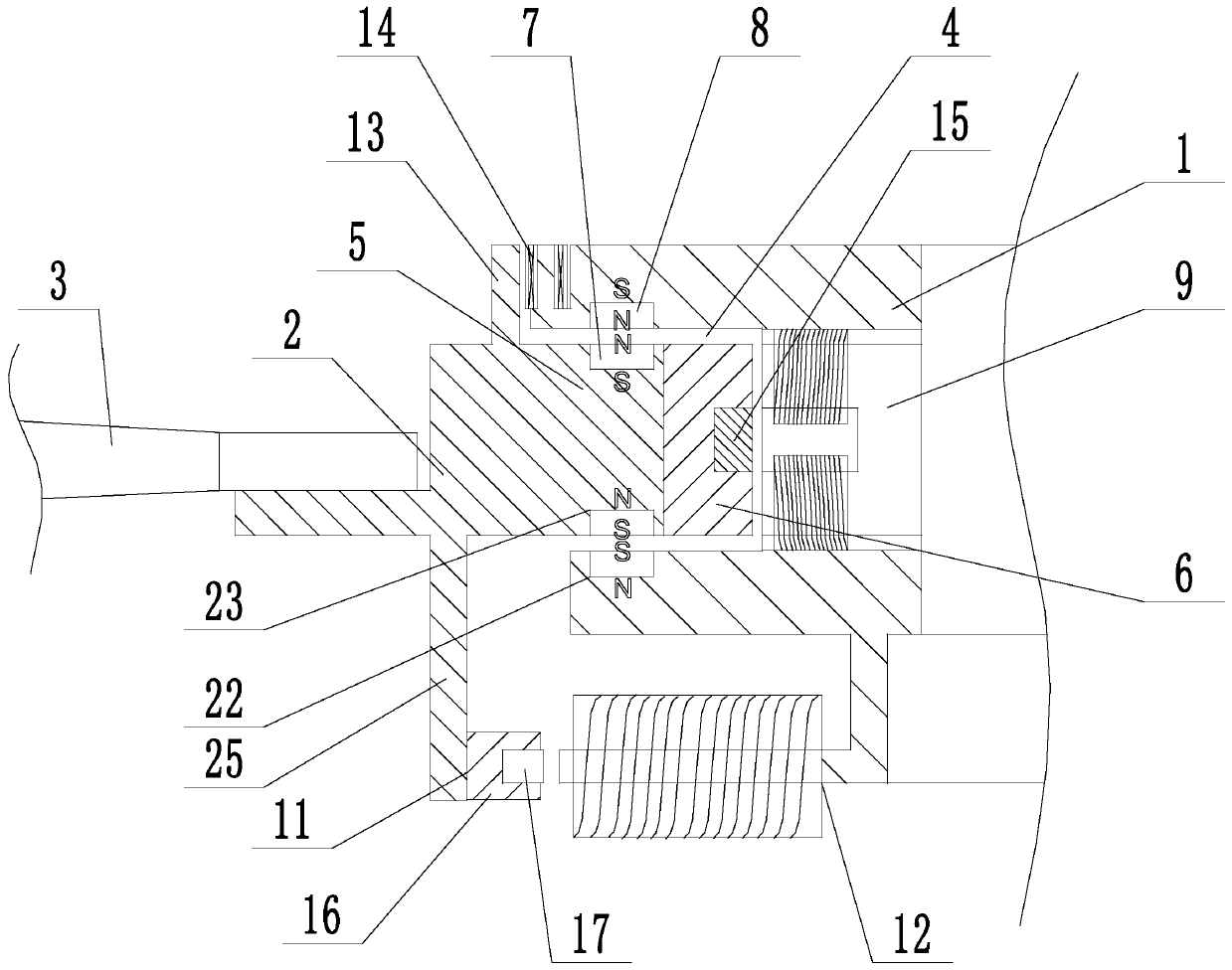

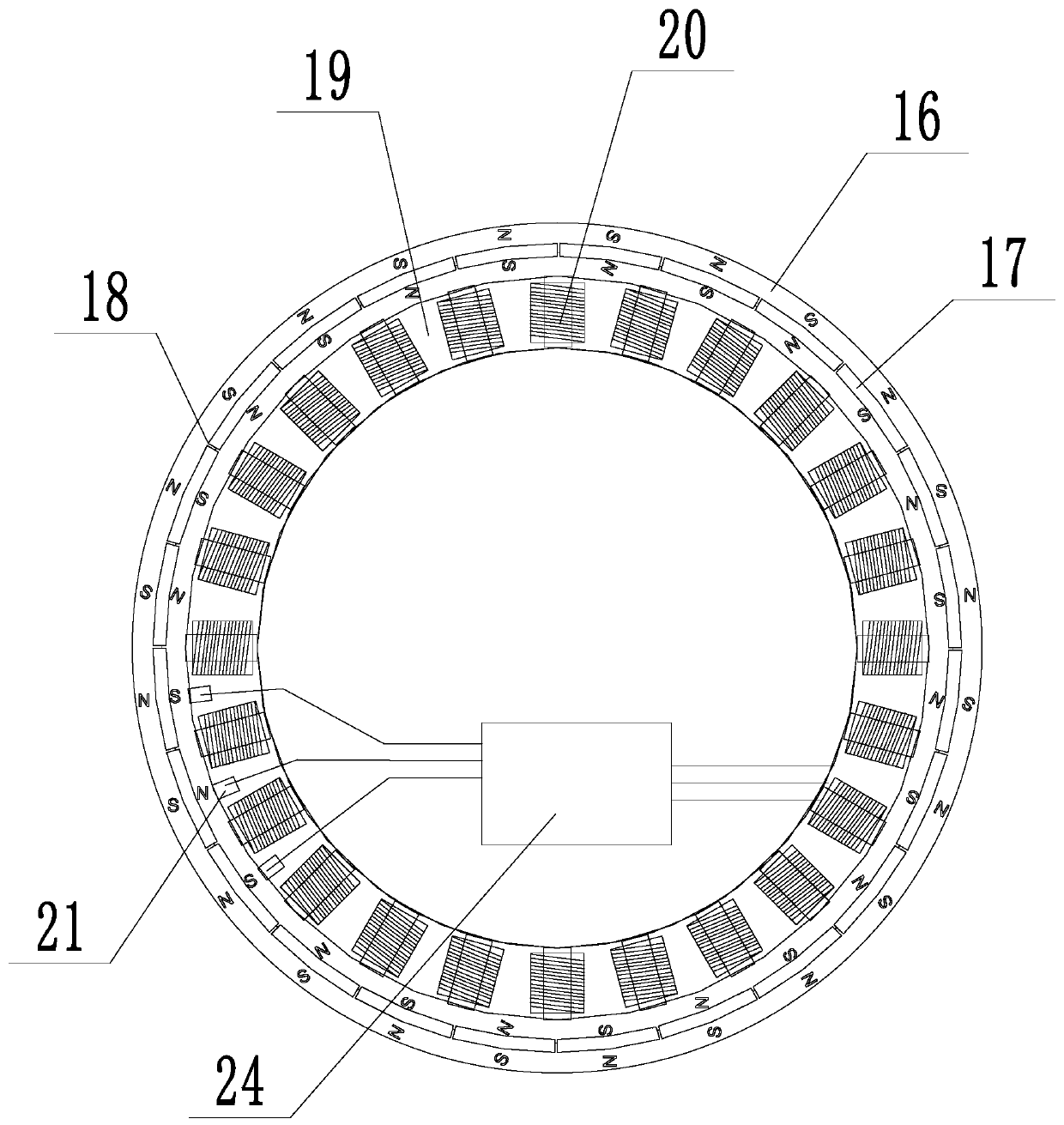

[0021] Embodiment: a kind of large-diameter annular magnetic levitation motor (see attached figure 1 to attach image 3 ), including a rotor fixing ring 1, a rotor rotor 2, and a control system 24. A plurality of propeller blades 3 are evenly distributed on the rotor rotor, an installation groove 4 is arranged on the outer wall of the rotor fixing ring axially arranged, and a suspension ring 5 is arranged on the rotor rotor. , the inner wall of the suspension ring axially installed adsorption ring 6, the adsorption ring is an iron ring, the suspension ring, the adsorption ring and the side wall of the installation groove are all provided with a suspension gap, and the upper and lower surfaces of the suspension ring are equipped with movable permanent Magnetic ring 7, fixed permanent magnetic ring 8 is installed on the side wall of the installation groove and the corresponding position of the movable permanent magnetic ring, and the opposite magnetic poles of the movable perman...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com