Patents

Literature

33results about How to "No lubrication required" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

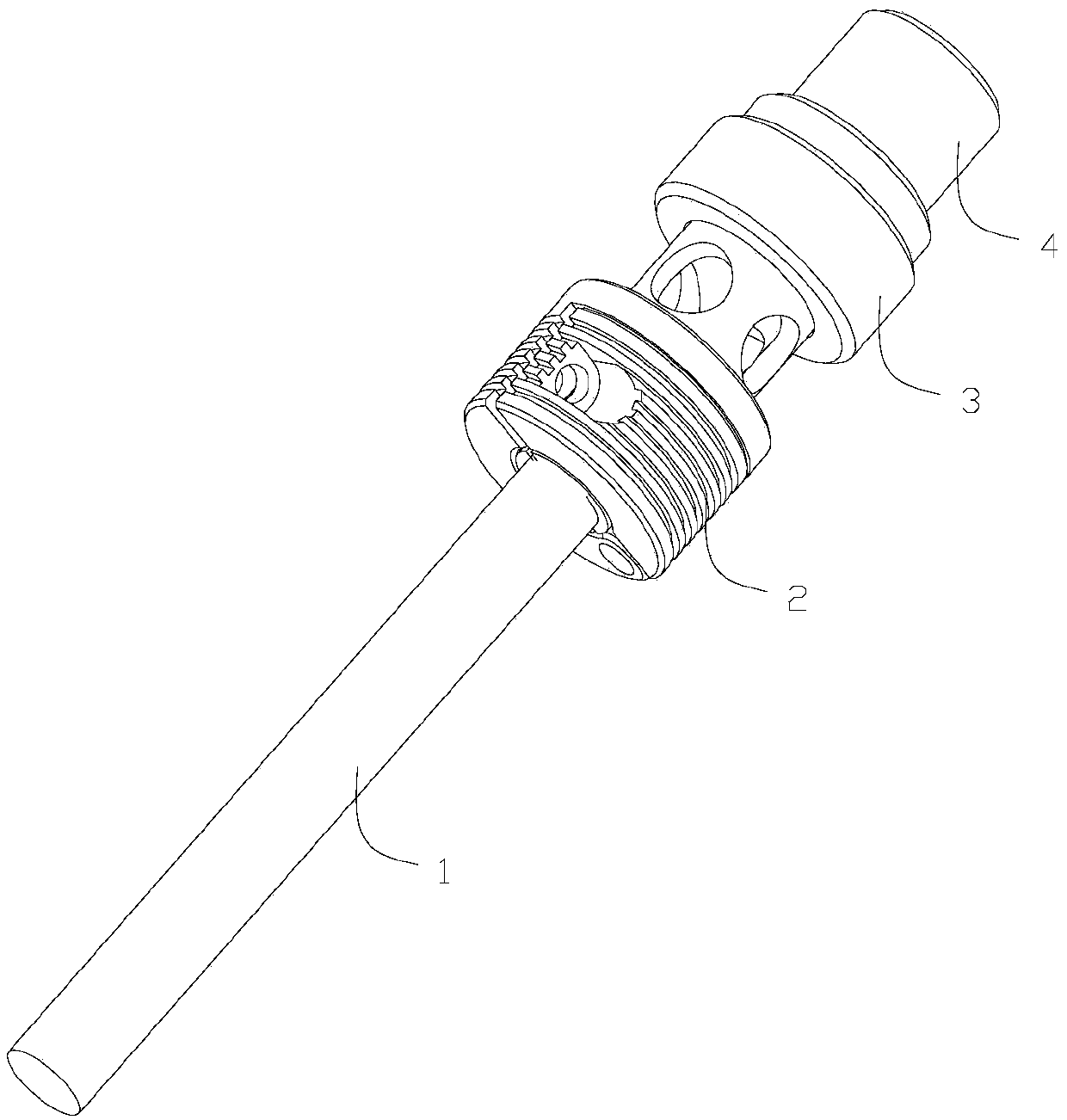

Ultrasonic/sonic wave sampler for drilling

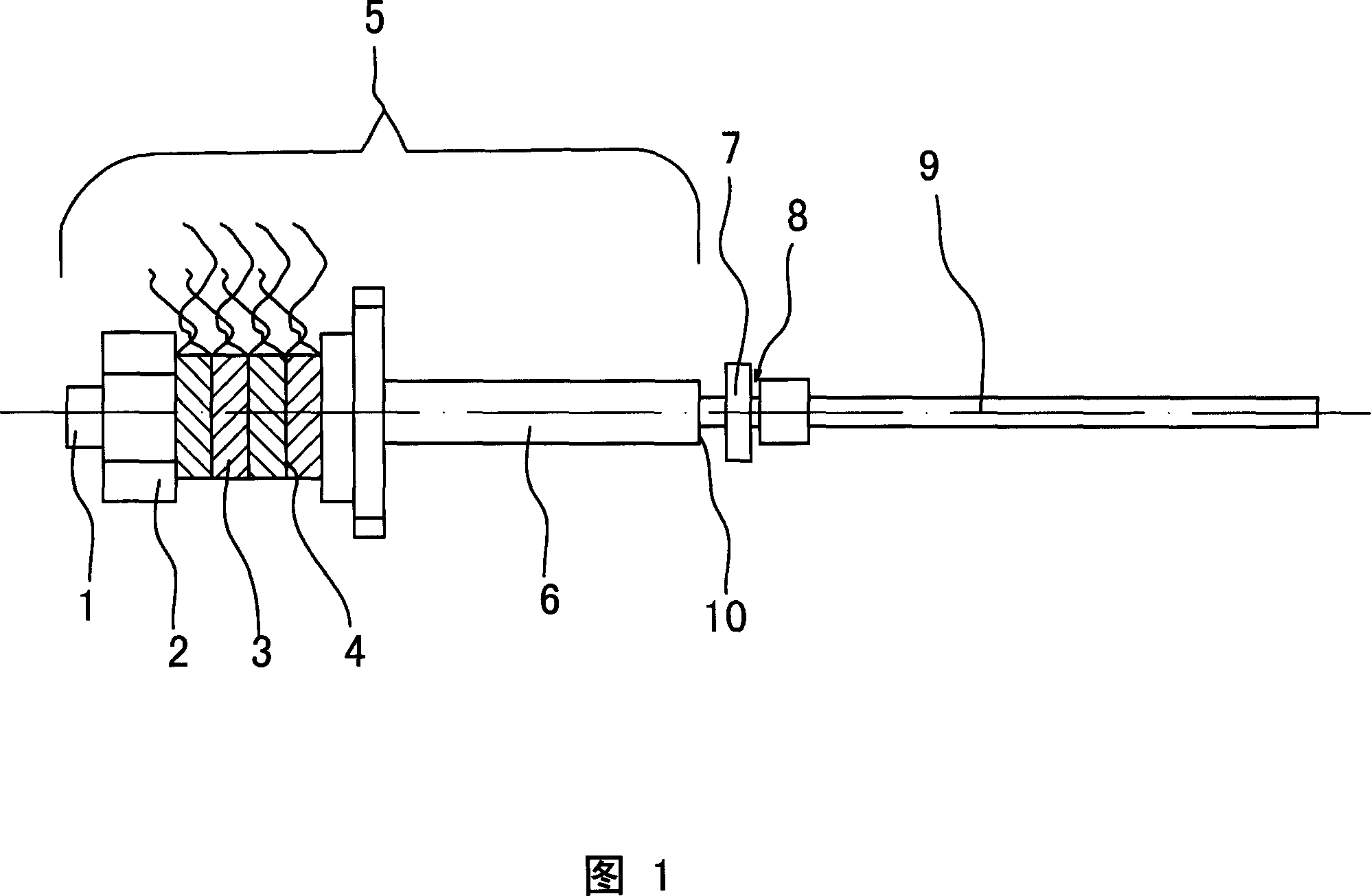

The ultrasonic wave / sonic wave drilling sampler capable of obtaining sample in other planet consists of three main parts: ultrasonic driver, free mass block and drilling rod. The ultrasonic driver consists of screw in the head, clamping piezoelectric ceramic chip in the tail and electrode plate. The ultrasonic driver generates resonance in ultrasonic frequency to be coupled acoustically with the free mass block so as to make the free mass block collide the journal of the drilling rod reciprocally at sound wave frequency. The collision and impact energy is transmitted via the bit to the drilled matter and sample is obtained from the broken matter. The drilling sampler has the features of being light and portable, low power consumption, no need of circumferential holding moment, no motion pair, no need of lubricating and powerful drilling capacity.

Owner:SUZHOU VOCATIONAL UNIV

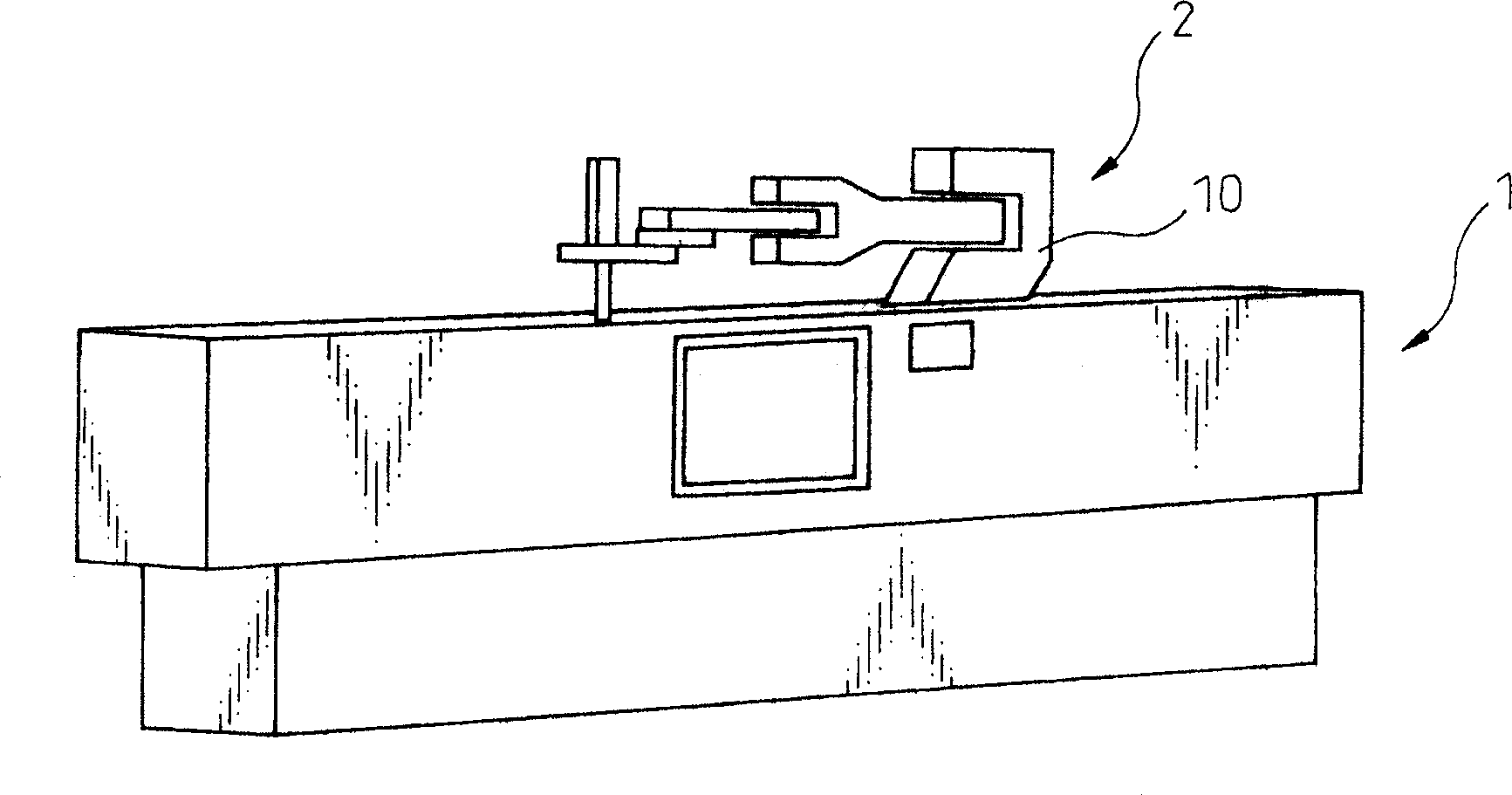

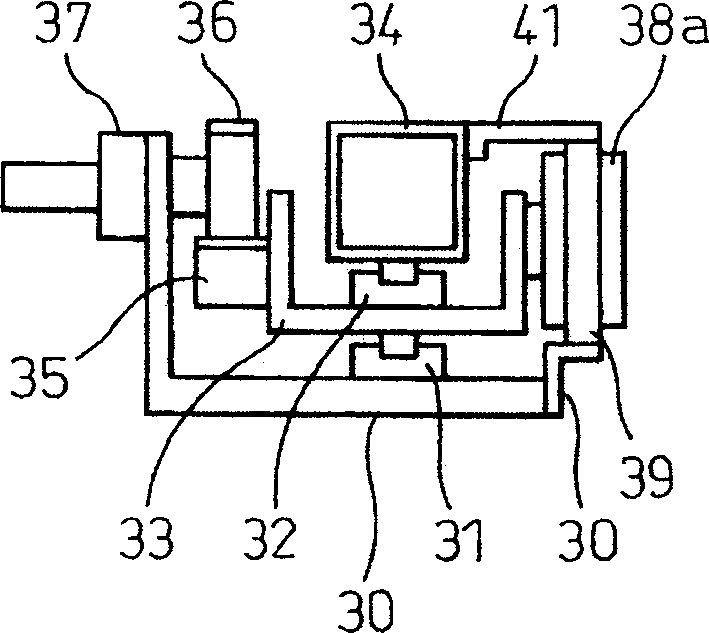

Molded-product removing device

InactiveCN1666854AReduce noiseNo lubrication requiredProgramme-controlled manipulatorArmsGear wheelPinion

Owner:FANUC LTD

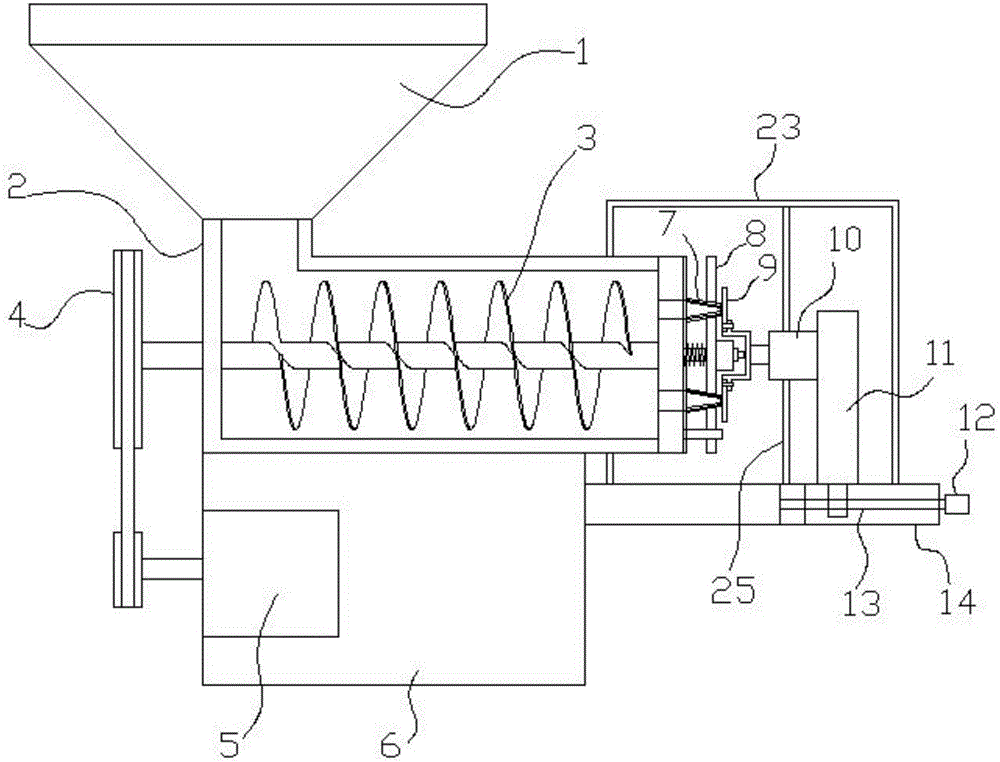

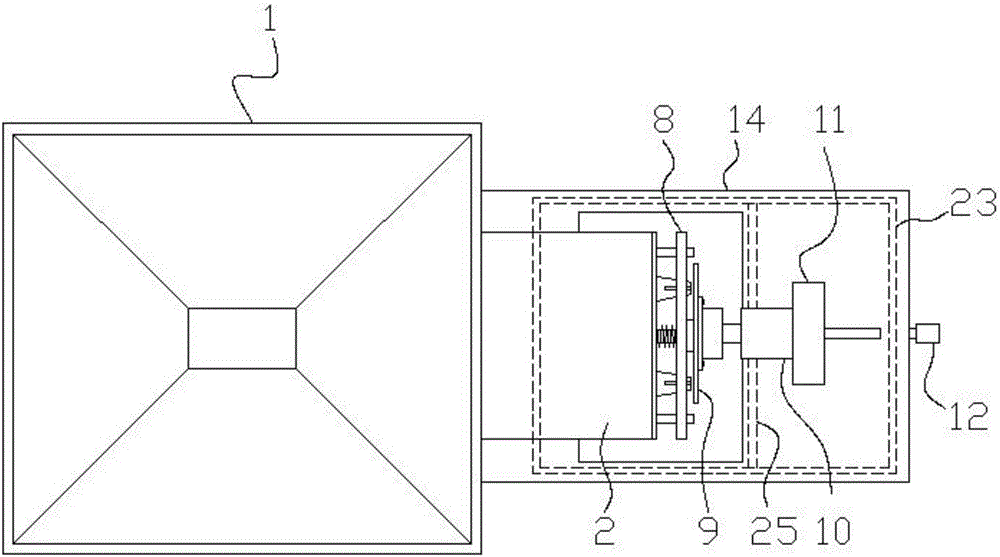

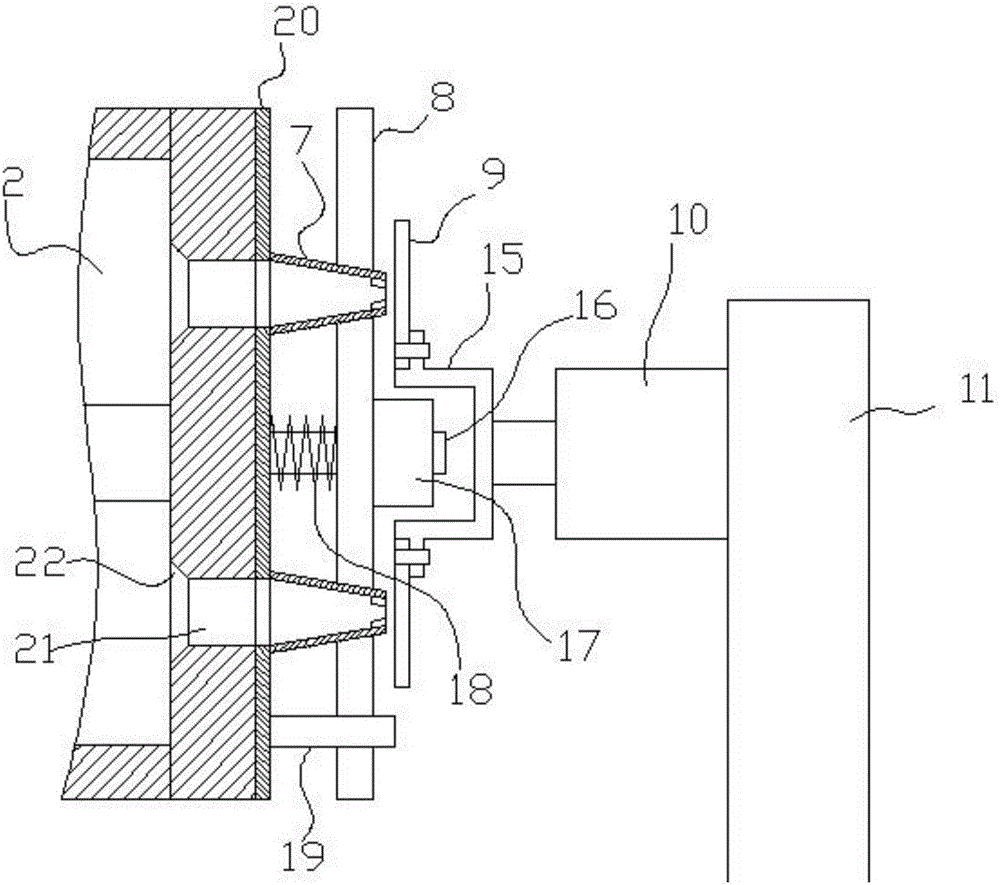

Extrusion cutting type multi-particle size adjustable granulating machine

ActiveCN106622022ALarge adjustment rangeEasy to adjustGranulation in rotating dishes/pansGranulation by material expressionPropellerAgricultural engineering

The invention discloses an extrusion cutting type multi-particle size adjustable granulating machine. The extrusion cutting type multi-particle size adjustable granulating machine comprises a stirring cylinder, wherein the stirring cylinder is arranged on a base, a spiral propeller is arranged in the stirring cylinder, and a material inlet hopper is arranged at the upper end of the stirring cylinder; the spiral propeller is connected with a propelling motor; a granulating disc is arranged at the front end of the stirring cylinder; conical granulating sleeves are uniformly arranged on the granulating disc, and are sheathed on an adjusting disc; a cutting tool disc is arranged at the front end of each conical granulating sleeve, and is fixedly arranged on a fixed disc; the fixed disc is connected with a cutting motor, and the cutting motor is arranged on a slide base; the slide base is connected with a screw rod in a bracket, and the bracket is connected with the base; an adjusting rotary button is arranged at the front end of the screw rod; each conical granulating sleeve is in a conical sleeve shape, and adjusting grooves are uniformly arranged at the front end of each conical granulating sleeve; mounting grooves are arranged on the inner walls of both sides of each adjusting groove; an arc-shaped movable plate is arranged in each mounting groove; outlet tool blades are uniformly arranged on the inner wall of the front end of each conical granulating sleeve. The extrusion cutting type multi-particle size adjustable granulating machine has the advantages that the quick and high-efficiency granulating function is realized, the granulating size can be adjusted, the adjusting range is wide, and the flexibility and convenience in use are realized.

Owner:湖南康易达绿茵科技有限公司

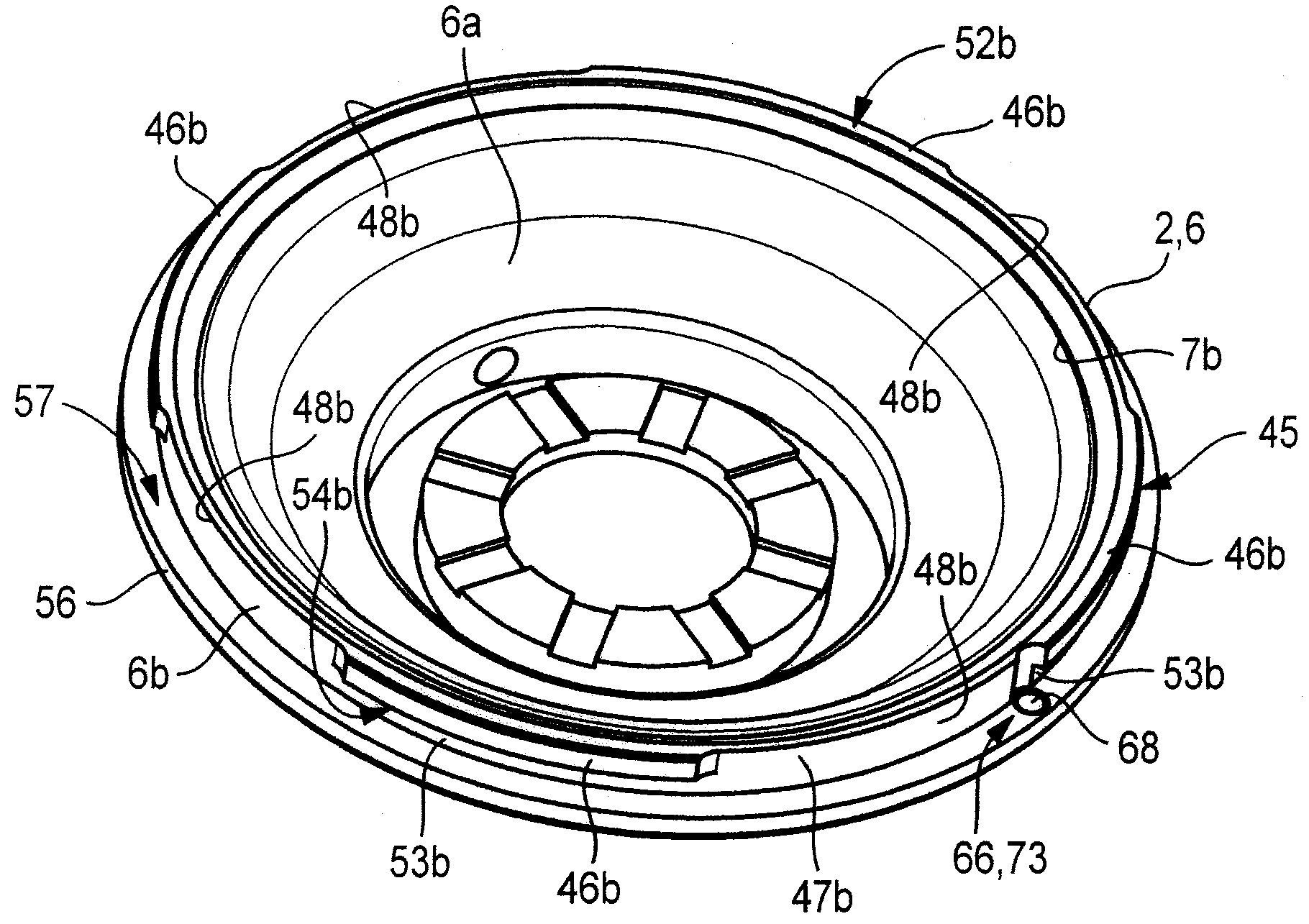

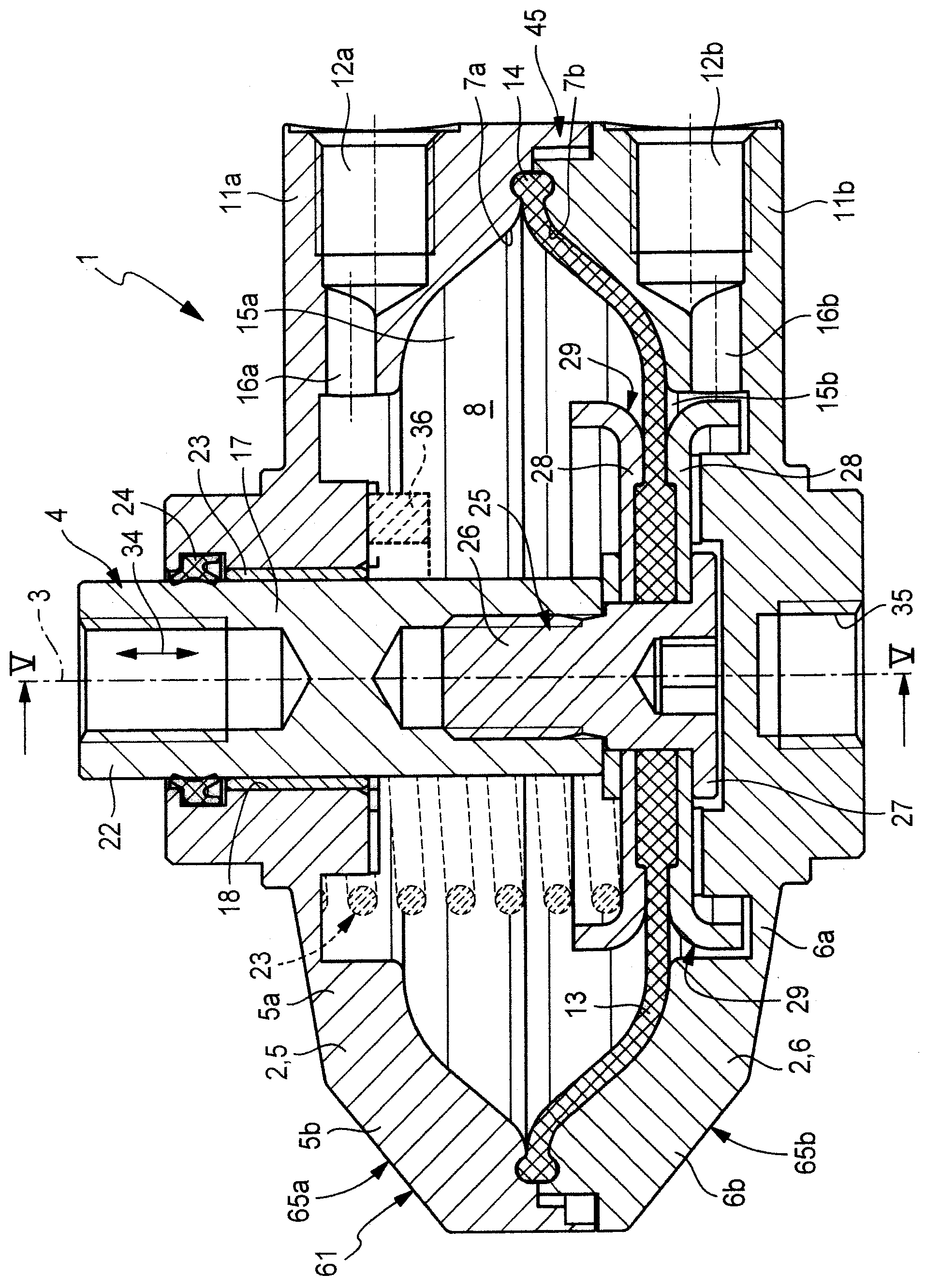

Fluid-actuated diaphragm drive

InactiveCN103443477AQuick and easy to assembleEasy to assembleFluid-pressure actuatorsEngineeringMechanical engineering

Owner:FESTO AG & CO KG

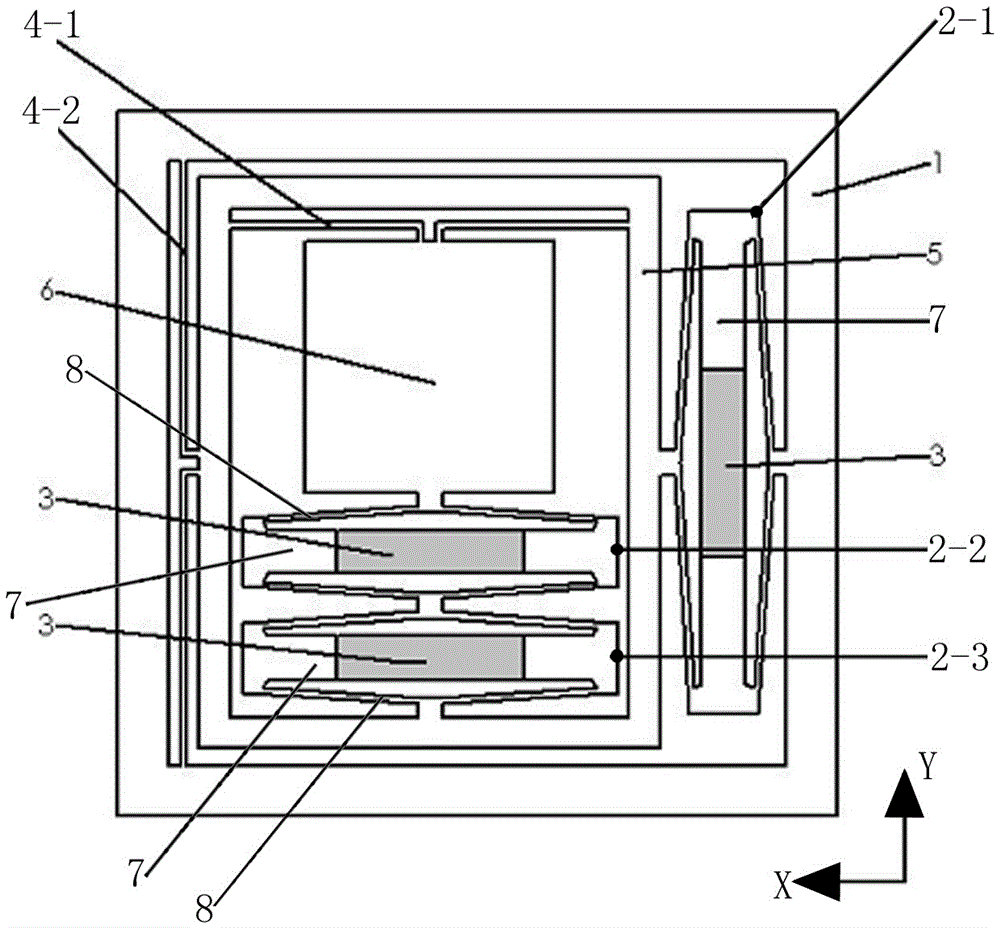

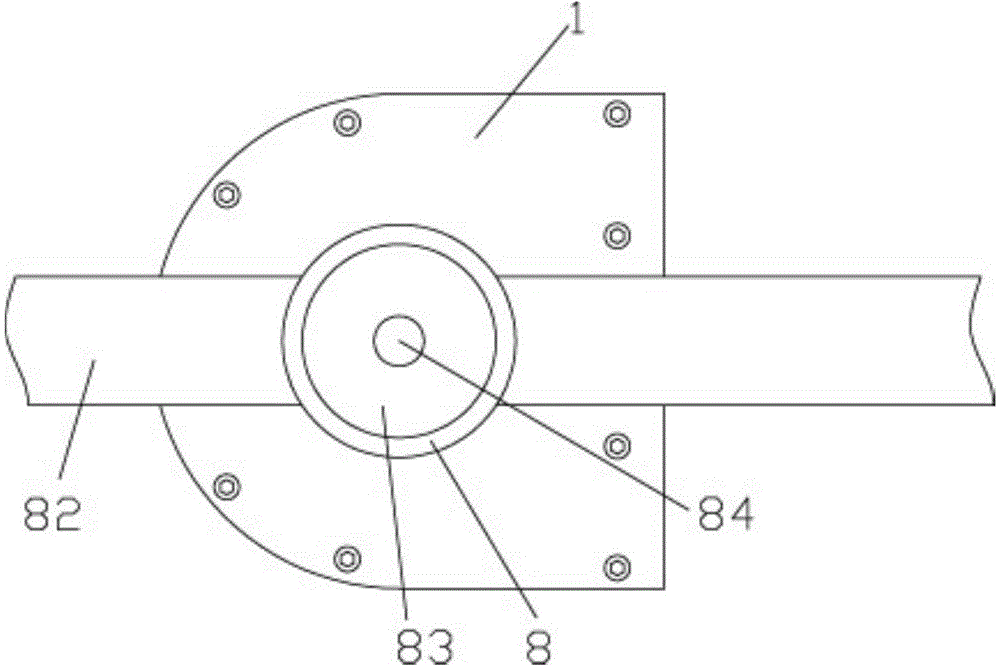

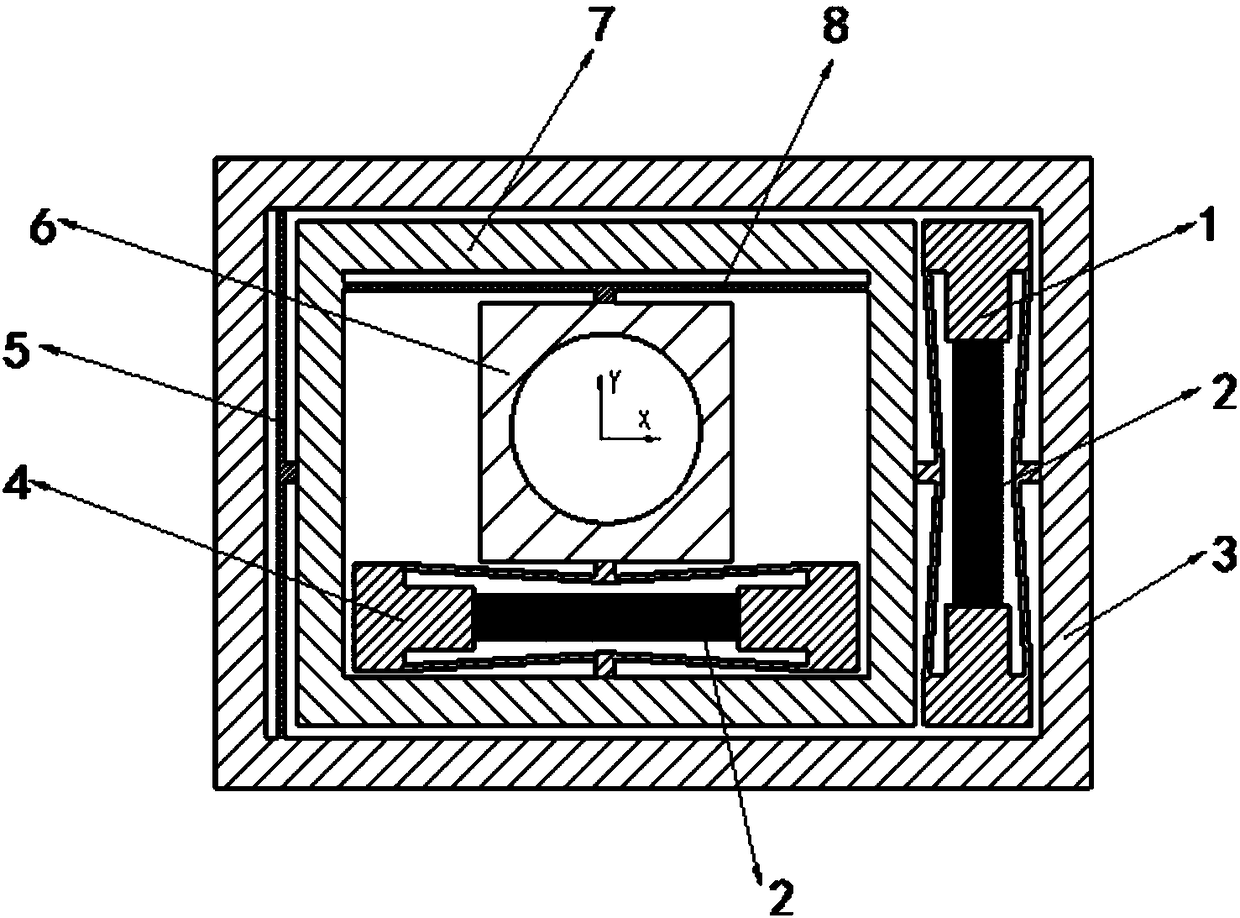

Piezoelectric driving large-stroke no-coupling two-dimensional precise micro locating platform

InactiveCN106373617ASolve the problem of small output displacementImprove working precisionInstrumental componentsIndependent motionImage resolution

Disclosed is a piezoelectric driving large-stroke no-coupling two-dimensional precise micro locating platform. The piezoelectric driving large-stroke no-coupling two-dimensional precise micro locating platform is characterize in that the platform comprises an outer layer support seat, a rhombus displacement magnifying mechanism, a piezoelectric ceramic actuator, symmetrical long arm hinges, an inner layer base plate and a workbench; and compared with the prior art, the platform has the advantages that 1, X-direction and Y-direction independent motion can be achieved, and X-direction and Y-direction simultaneous motion can also be achieved; 2, the maximum displacement output quantities in the X direction and the Y direction are close; 3, displacement quantity can be increased, coupling is eliminated, and error is reduced; and 4, the platform has the advantages that mechanical friction, delaying and clearance are avoided, lubrication is not needed, heat and noise are not produced, and the motion resolution is high.

Owner:SHENYANG POLYTECHNIC UNIV

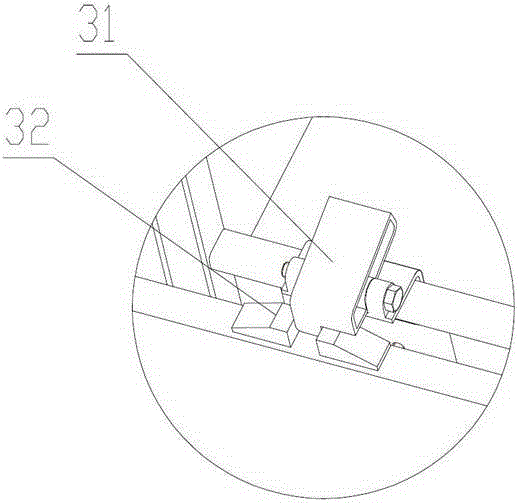

Upper platform extending limiting device of aerial work platform

InactiveCN105271079AReduce in quantityReliable returnSafety devices for lifting equipmentsLocking mechanismEngineering

The invention discloses an upper platform extending limiting device of an aerial work platform. The upper platform extending limiting device comprises an upper platform body and an extending part. The extending part is installed in the upper platform body and can slide in the length direction of the upper platform body. A limiting assembly is arranged between the upper platform body and the extending part. The limiting assembly comprises a locking mechanism and a limiting block. The locking mechanism is installed on the extending part. The limiting block is installed on the upper platform body. The locking mechanism slides to the limiting block of the upper platform body along the extending part to achieve limiting fixing. The upper platform extending limiting device is simple in structure and convenient to control, and the construction safety of personnel is improved.

Owner:JIANGSU LIUGONG MACHINERY

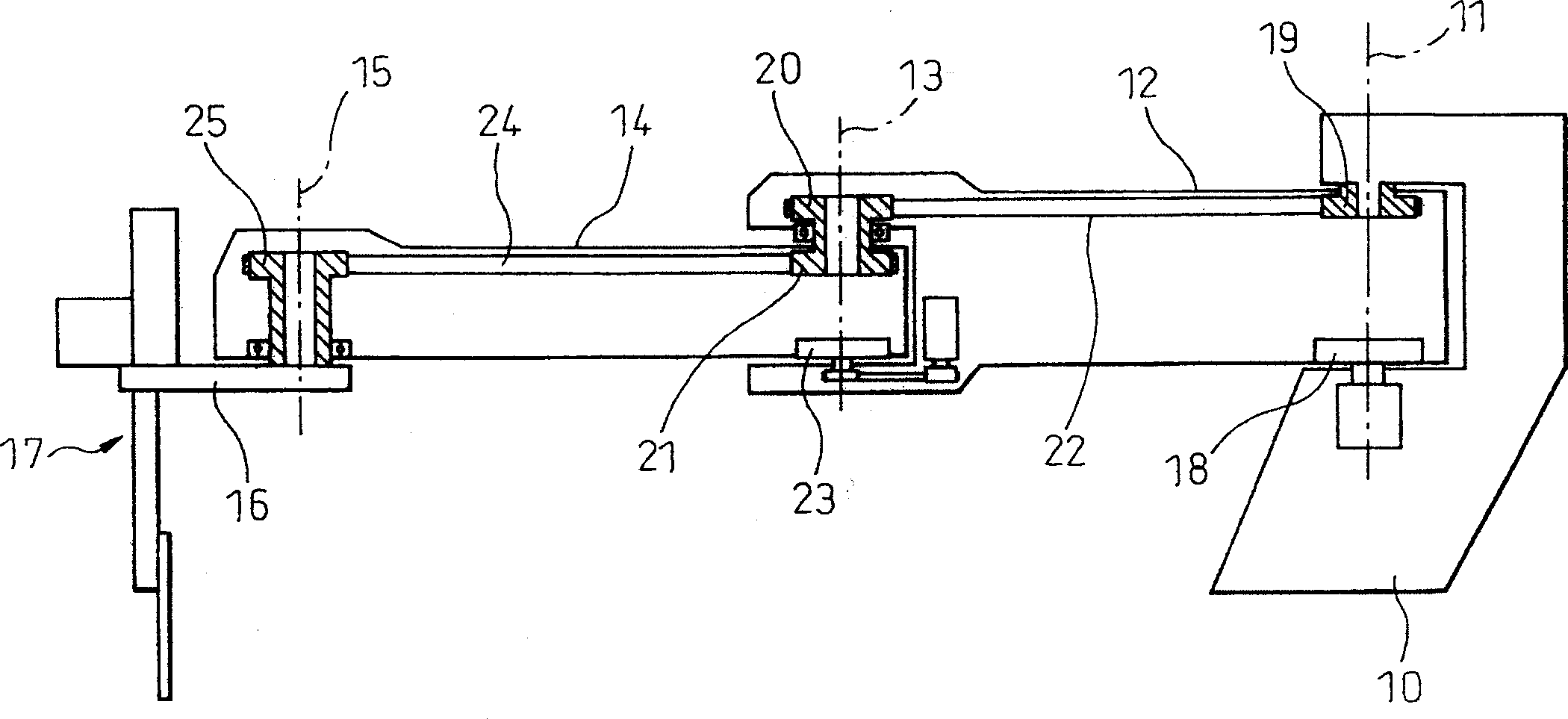

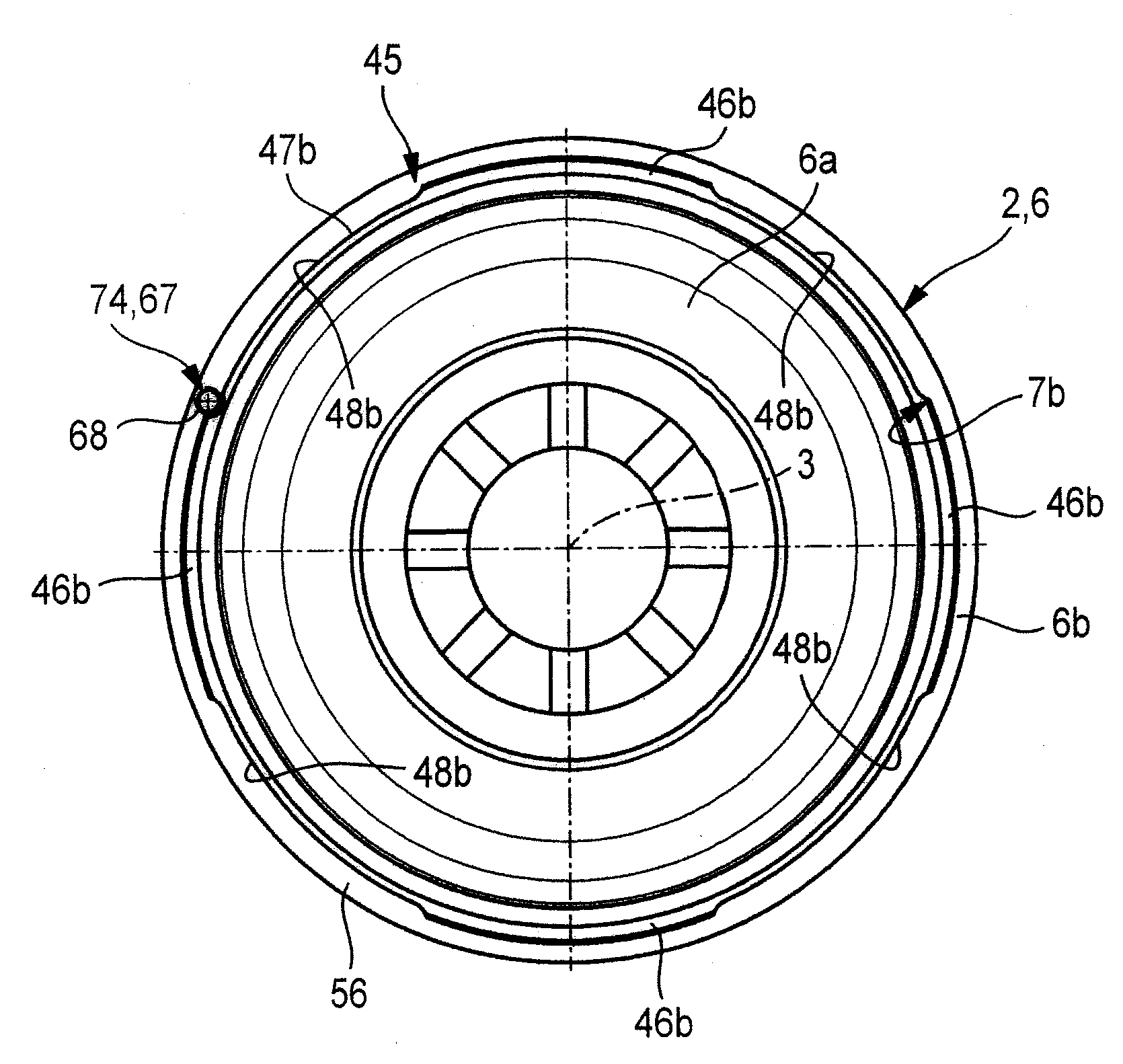

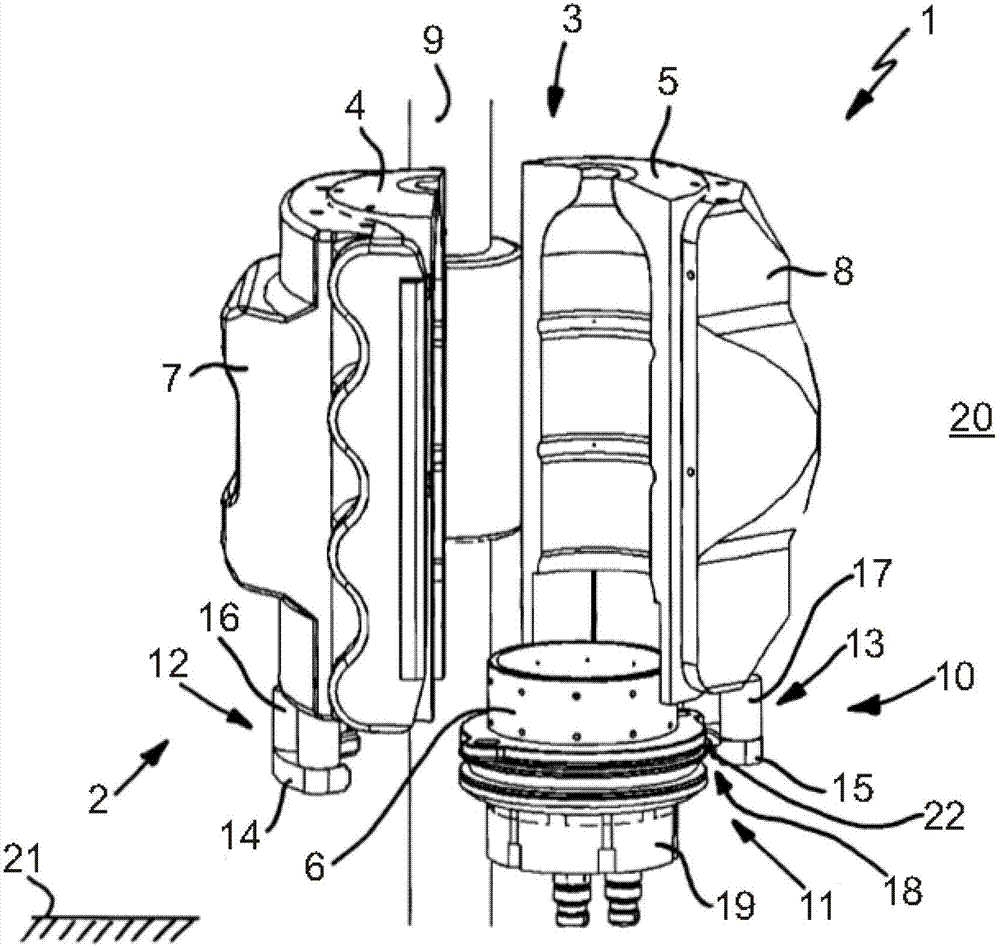

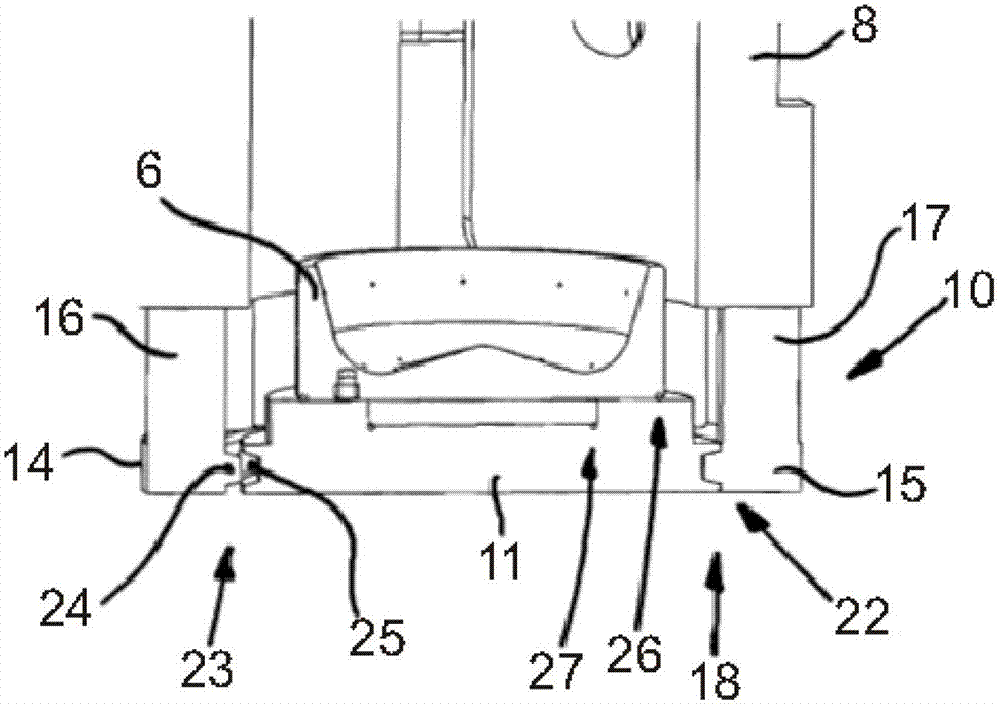

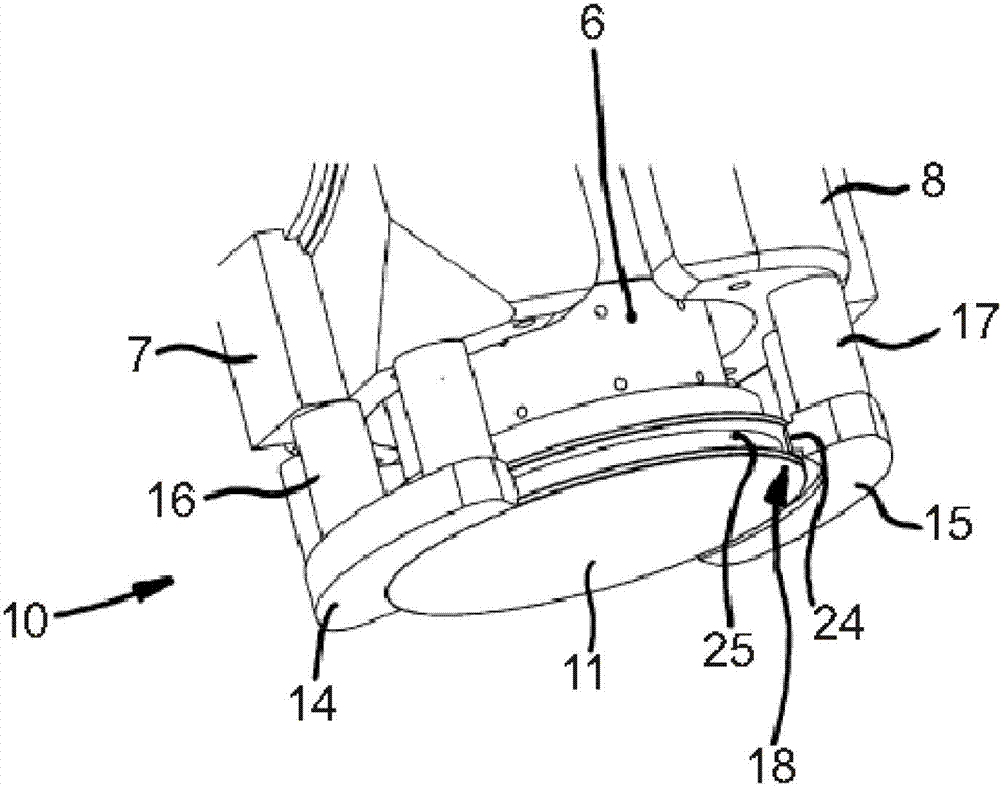

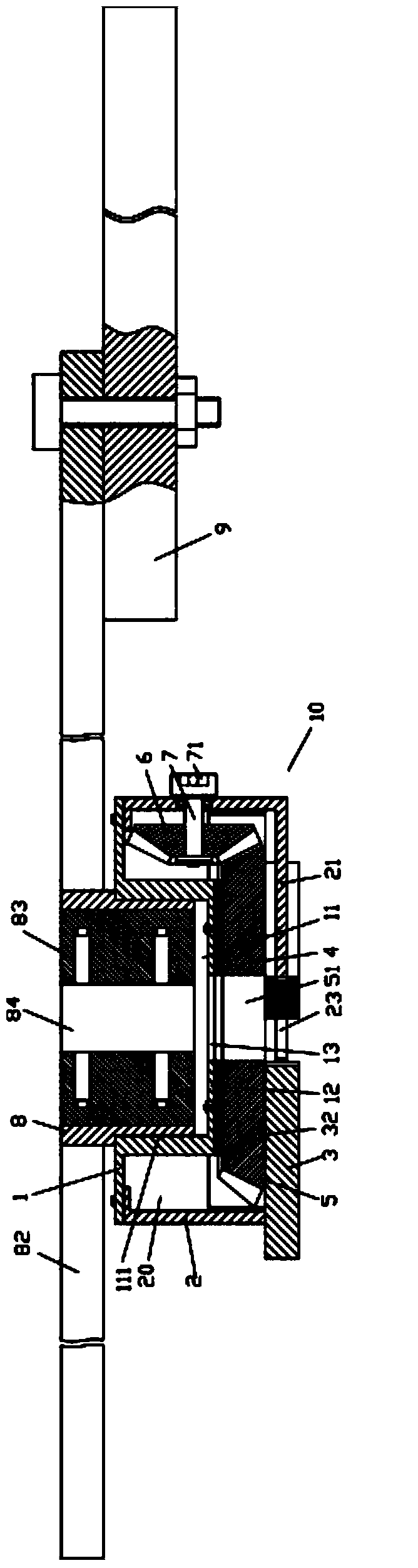

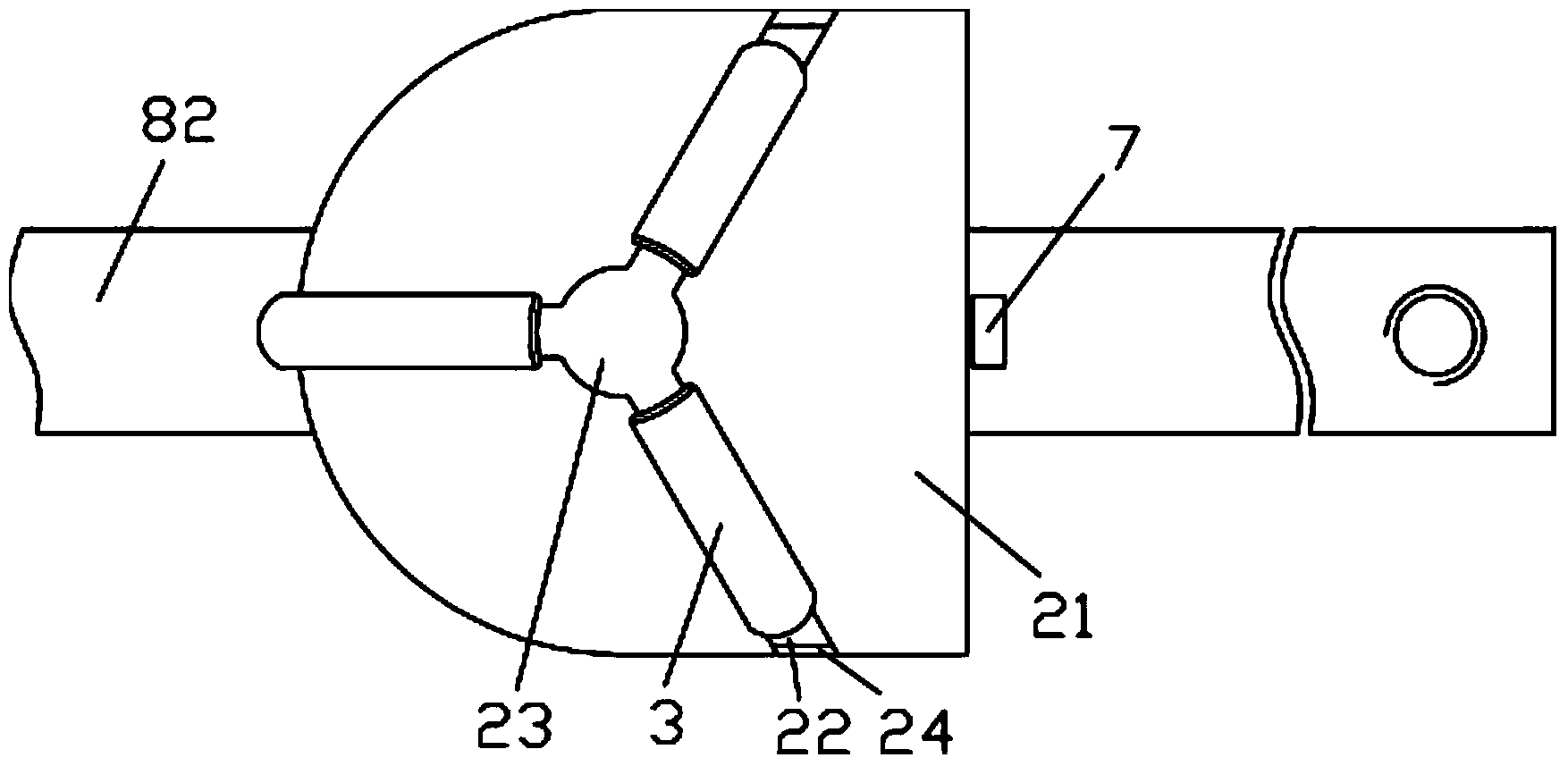

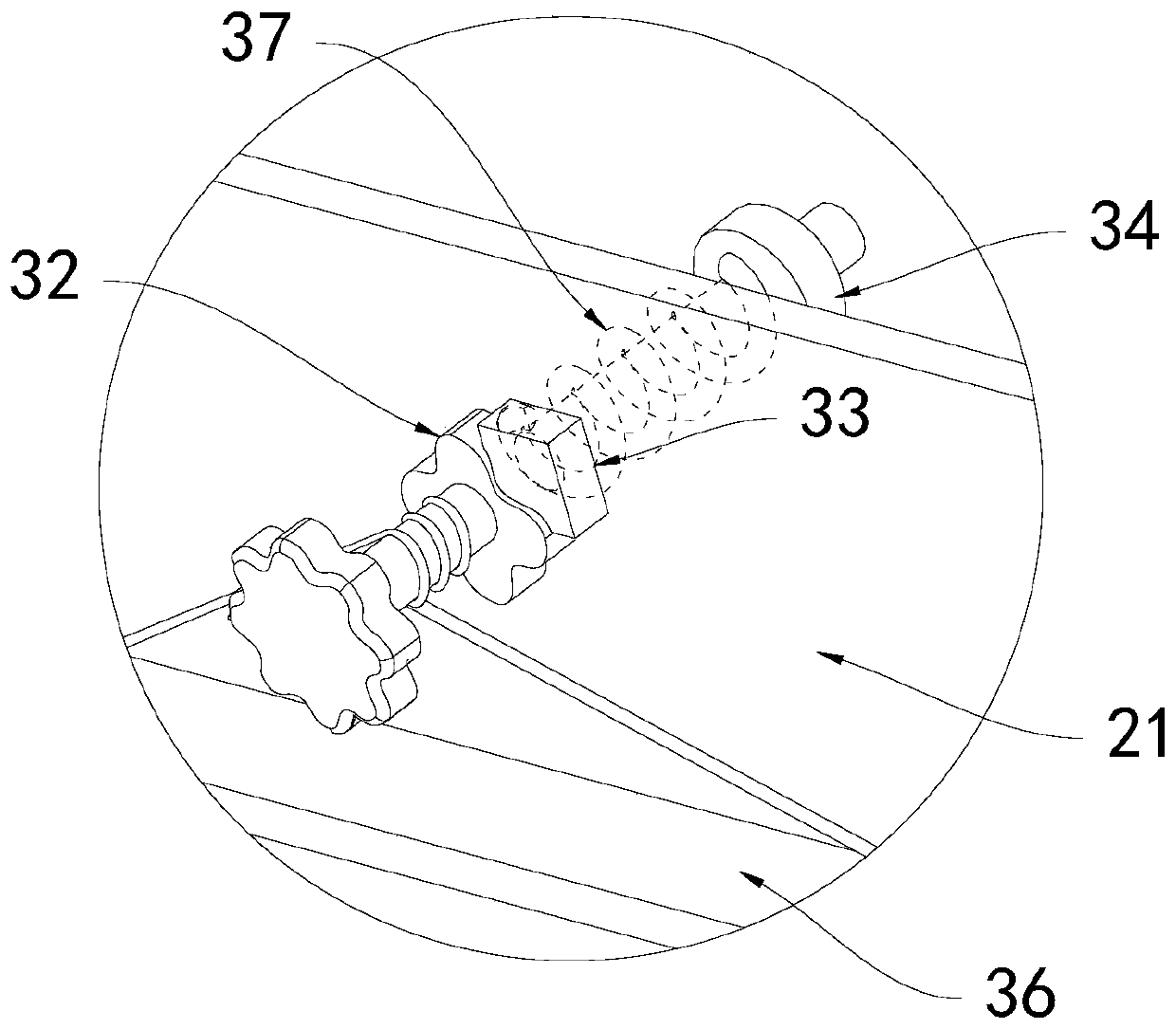

Stretch-blow molding apparatus and equipment of plastic material perform and application of ceramic member

InactiveCN102806655AGood sliding propertiesImprove the stabilityLoad modified fastenersBoltsBlow moldingEngineering

The invention relates to apparatus (1) which perform stretching and blow molding on a plastic material perform to form a plastic material container. The apparatus (1) has a bearing assembly (2) used for bearing a blow-molding die (3) comprising at least two housing components (4, 5) and a base component (6), and has a base component clamping assembly comprising a base component accommodating mechanism (11; 111) and used for holding a holding assembly (12, 13 and 14, 15; 114, 115 respectively) of the base component accommodating mechanism (11; 111), wherein the base component accommodating mechanism (11; 111) can be clamped to the holding assembly (12, 13 and 14, 15; 114, 115 respectively) via a forced interlocking fastening part (18; 118), and the forced interlocking fastening part (18; 118) has a forced interlocking area (22) made of ceramic materials.

Owner:KRONES AG

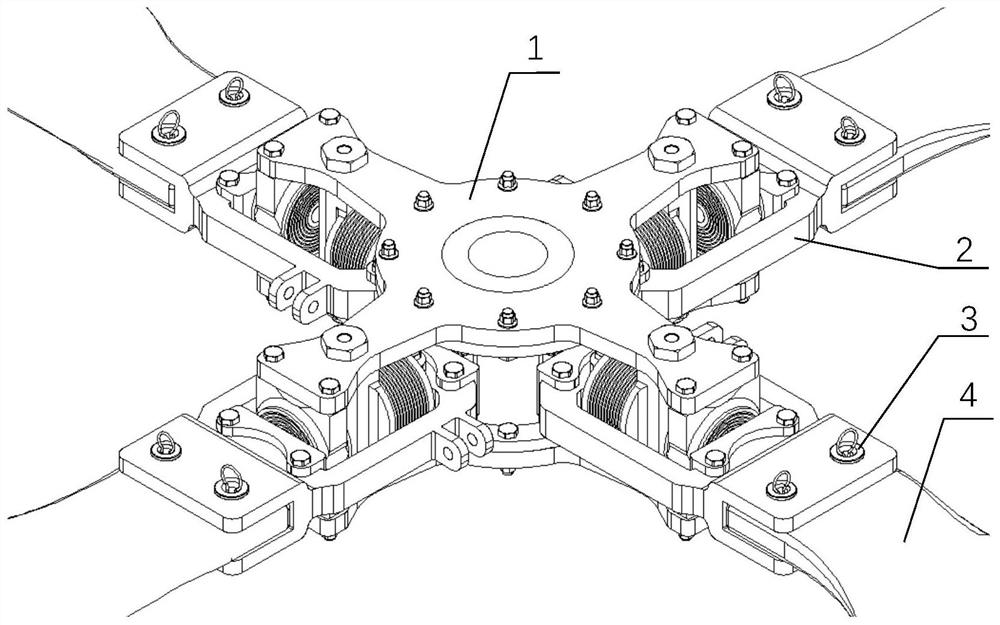

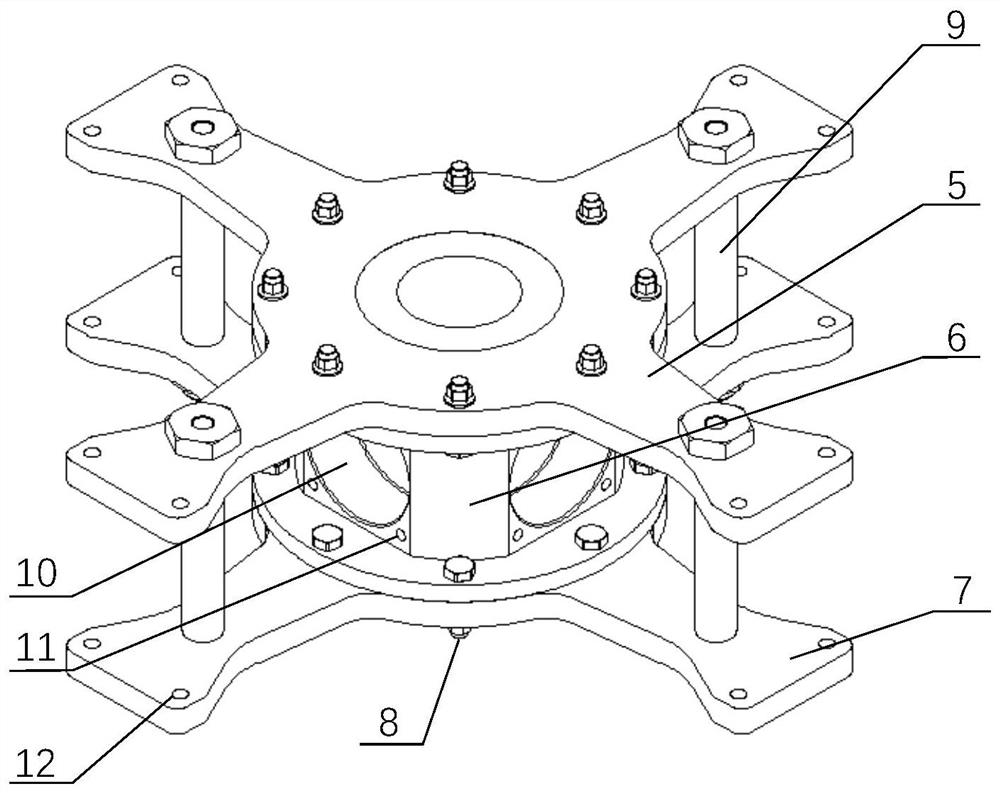

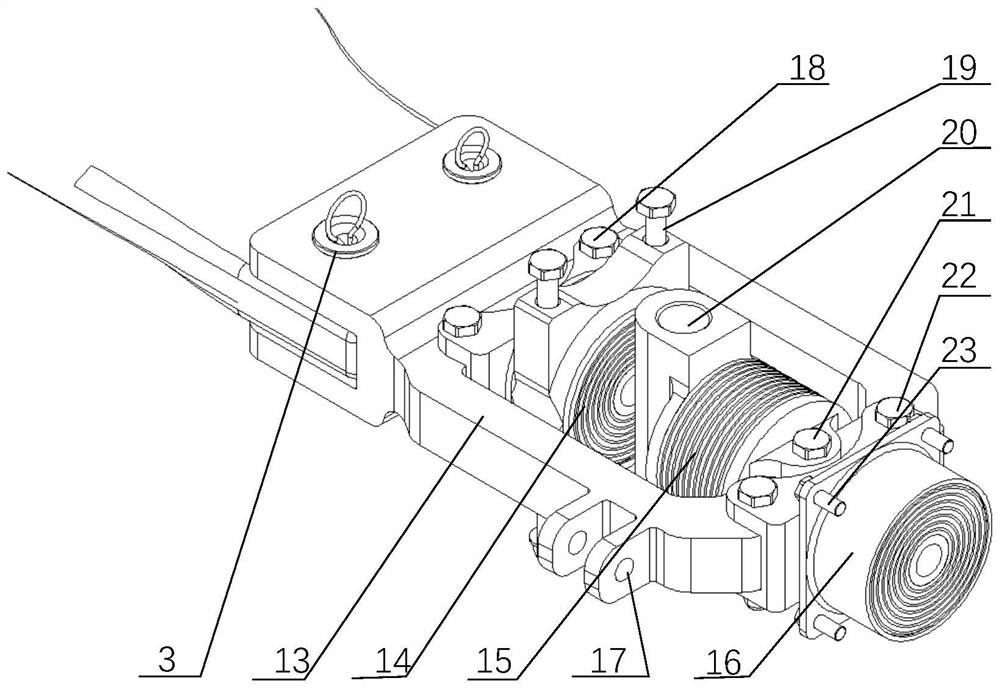

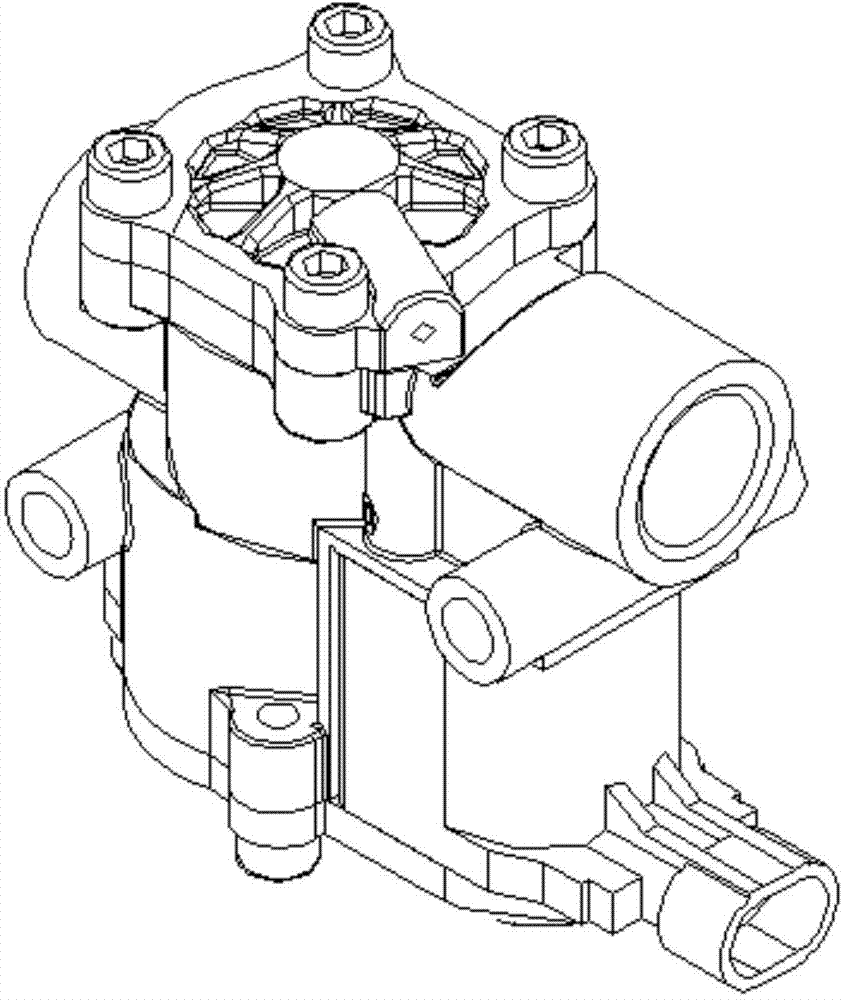

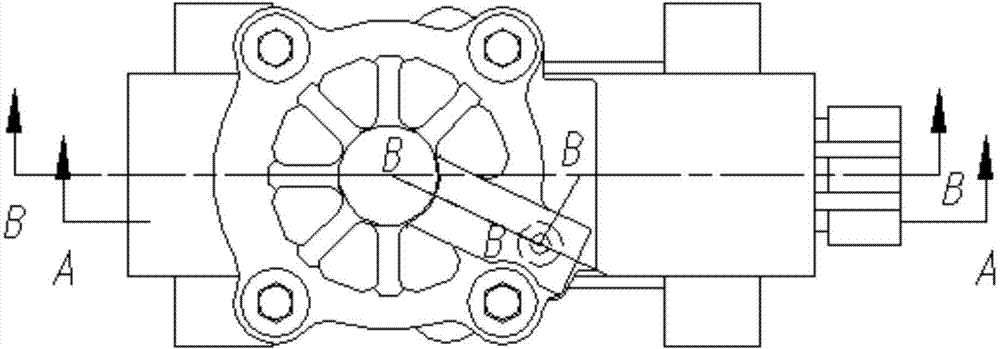

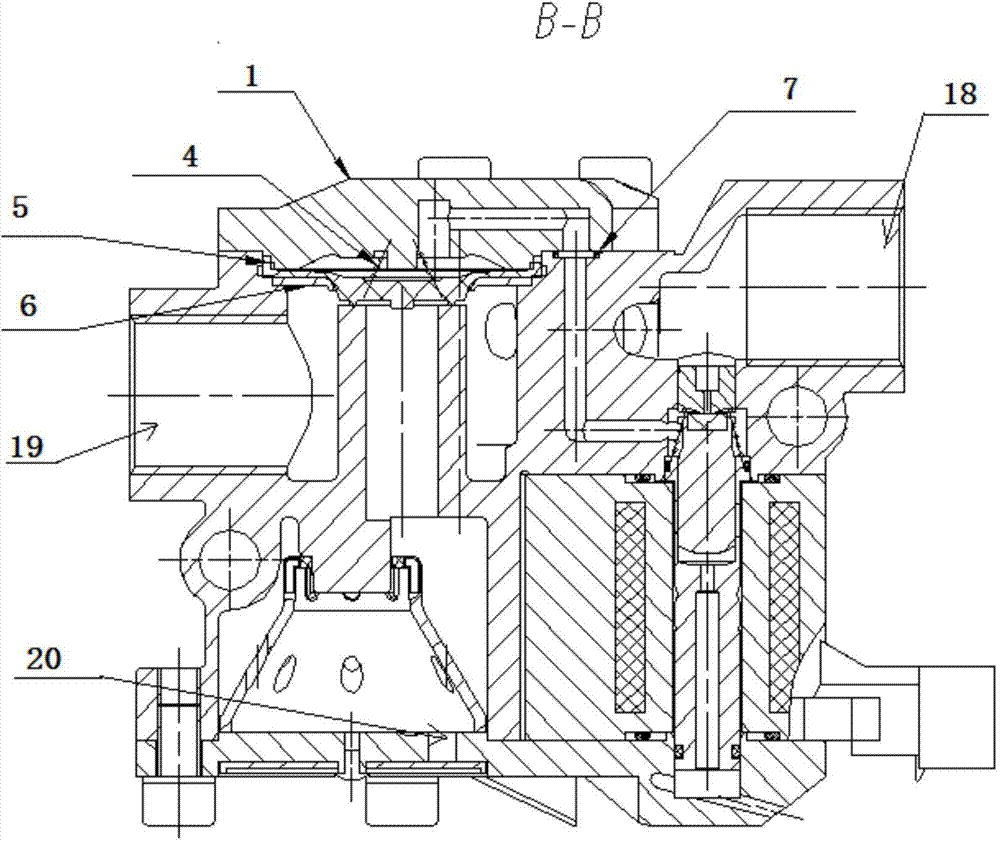

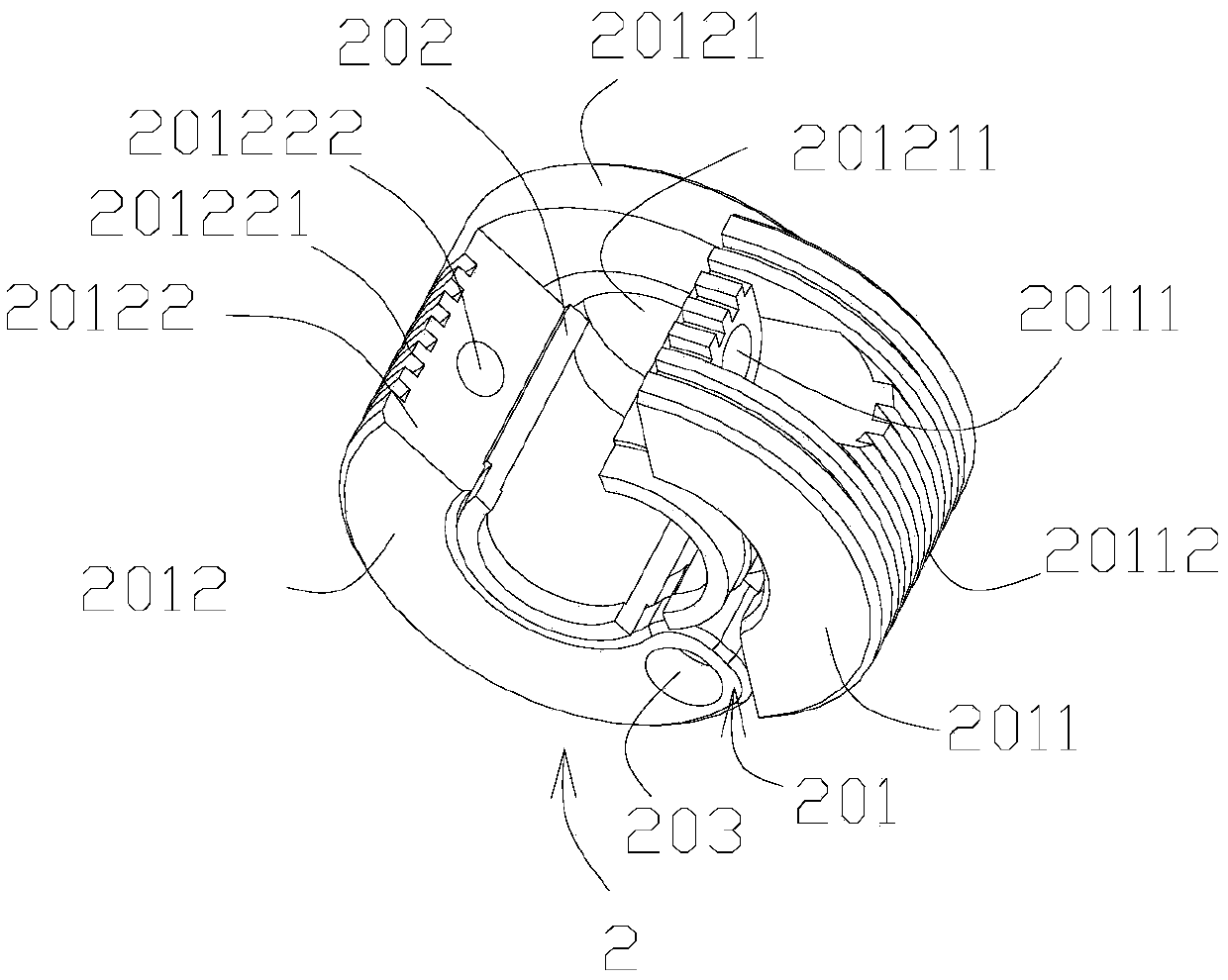

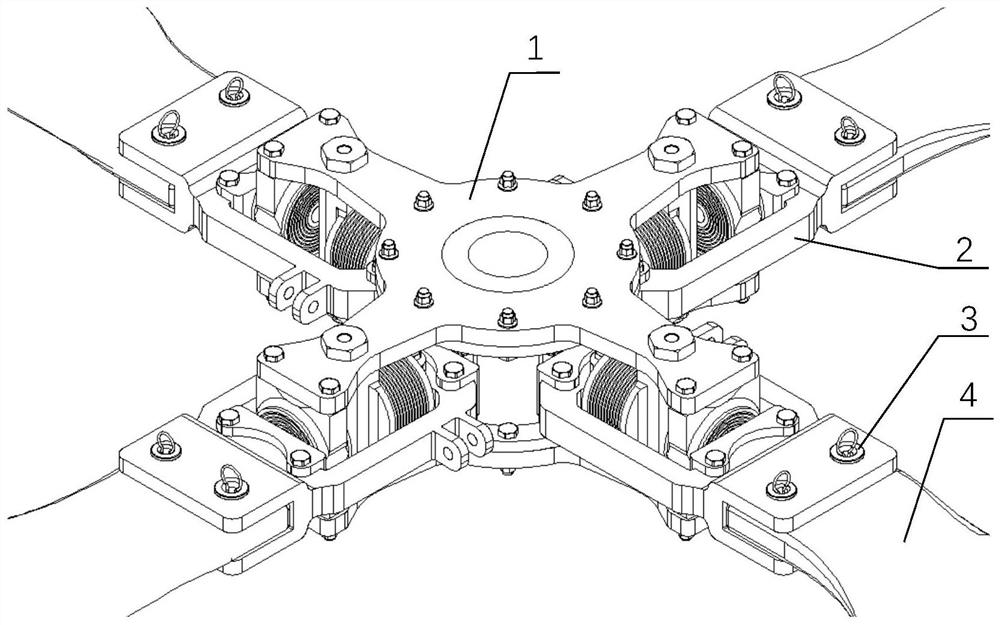

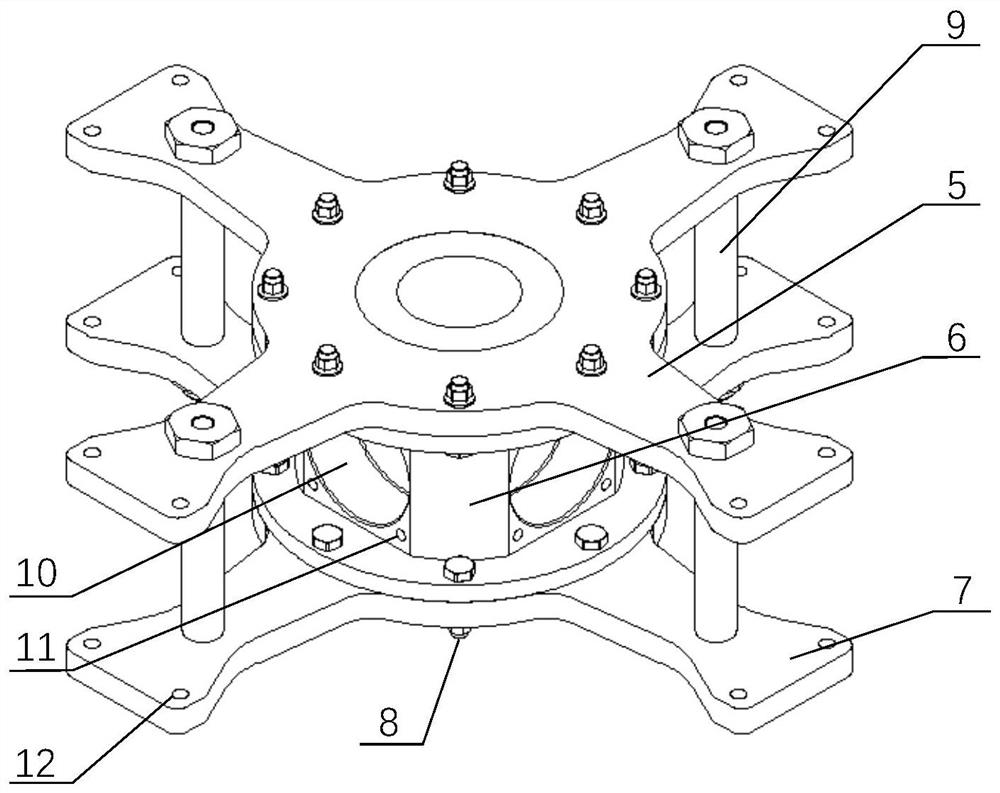

Rigid rotor hub of helicopter

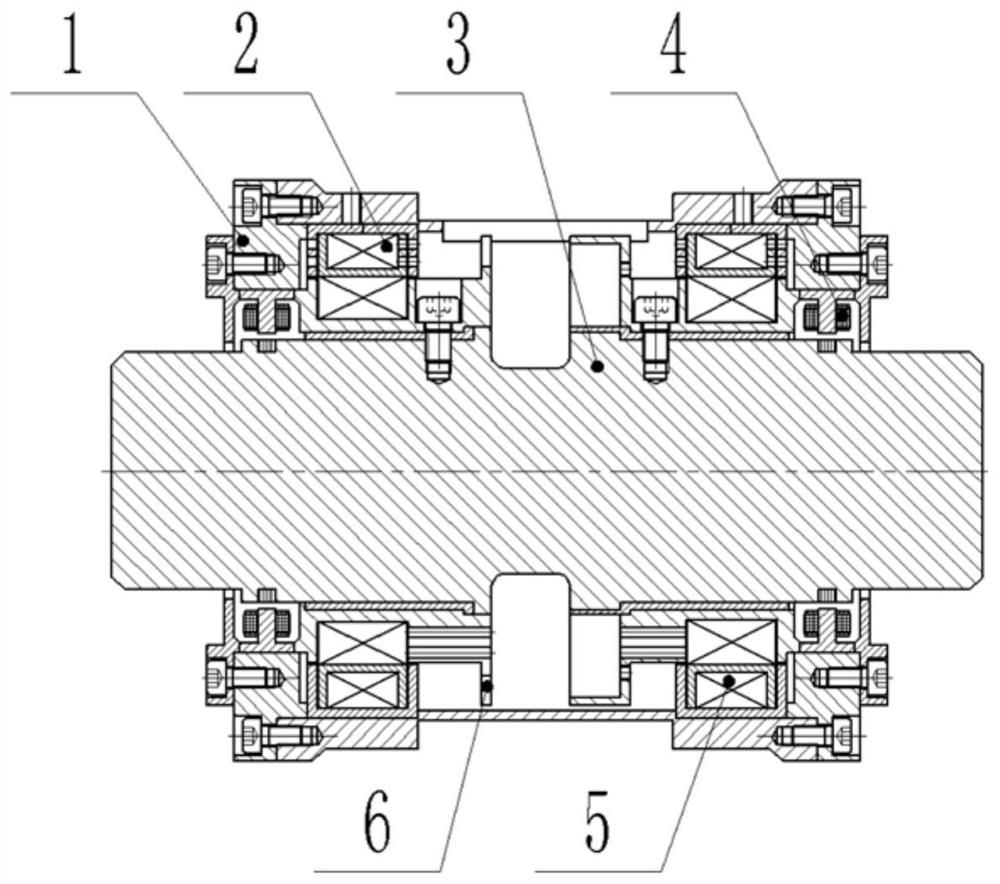

ActiveCN112046739AGuaranteed stiffnessChange dynamicsPropellersRotocraftRigid rotorAerospace engineering

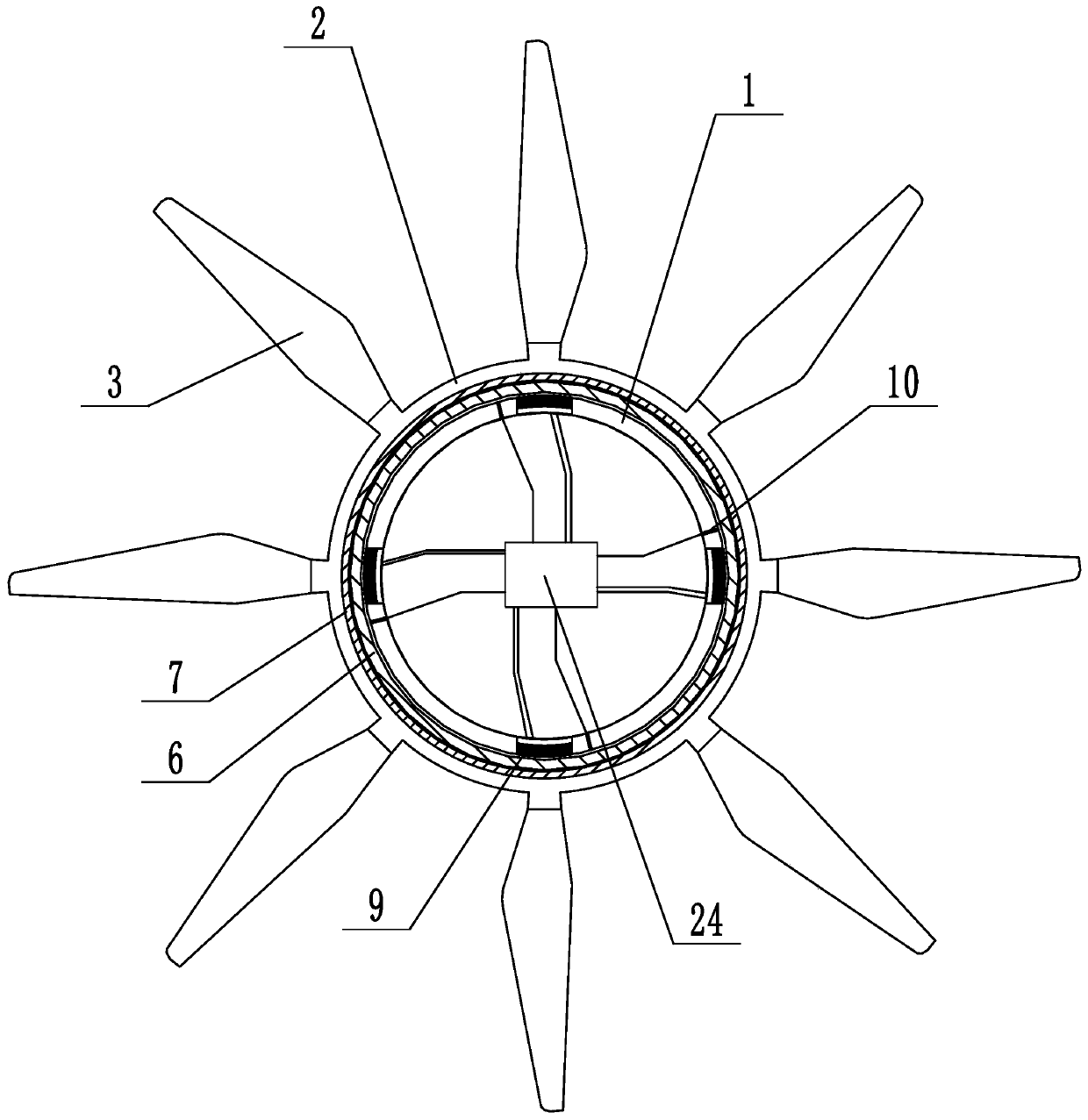

The invention discloses a rigid rotor hub of a helicopter. A plurality of variable-pitch arm modules are arranged around a center piece module; paddles are fixed on the variable-pitch arm module; eachvariable-pitch arm module comprises a paddle mounting base, an outer side radial laminated elastic bearing, a thrust laminated elastic bearing and an inner side radial laminated elastic bearing; thepaddles are fixed on the paddle mounting bases; the outer side radial laminated elastic bearings and the inner side radial laminated elastic bearings have the same structure; an inner ring of each outer side radial laminated elastic bearing is fixed on the corresponding paddle mounting base, and an outer ring of each outer side radial laminated elastic bearing is fixed on the center piece module;an inner ring of each inner side radial laminated elastic bearing is fixed on the corresponding paddle mounting base, and an outer ring of each inner side radial laminated elastic bearing is fixed with the center piece module; each thrust laminated elastic bearing is composed of laminated elastic layers stacked in the axial direction, the inner side of each thrust laminated elastic bearing is fixed to the corresponding paddle mounting base, and the outer side of each thrust laminated elastic bearing is fixed to the center piece module; and the axes of the three elastic bearings of each variable-pitch arm module are collinear. The rigid rotor hub has the advantages of being long in service life and free of lubrication and maintenance, having no abrasion, and the like.

Owner:NO 60 RES INST OF GENERAL STAFF DEPT PLA

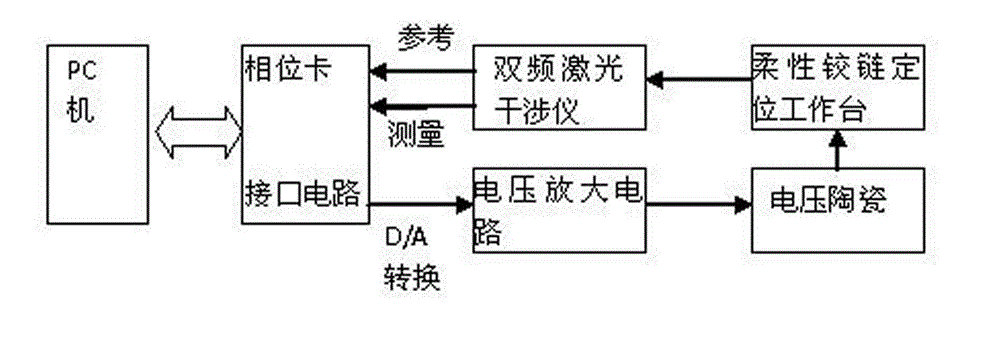

Ultra precision positioning workbench with nanometer resolution

The invention relates to a positioning workbench, in particular to an ultra precision positioning workbench with nanometer resolution. The ultra precision positioning workbench with the moving precision and positioning precision can be in the sub micron or even nanometer level. The workbench comprises a soft hinge workbench body and a piezoelectric ceramic micro displacement device and is characterized in that a dual frequency laser interferometer (SJD5) is adopted for detection, and a loop control system is obtained through a computer and a phase meter; digital signals are transmitted the computer and are converted and amplified through a D / A converter, the 0 to 1000V variable voltage with the step of 1 V is produced to drive the piezoelectric ceramic to stretch, and the piezoelectric ceramic drives the soft hinge workbench body to perform micro displacement.

Owner:李志刚

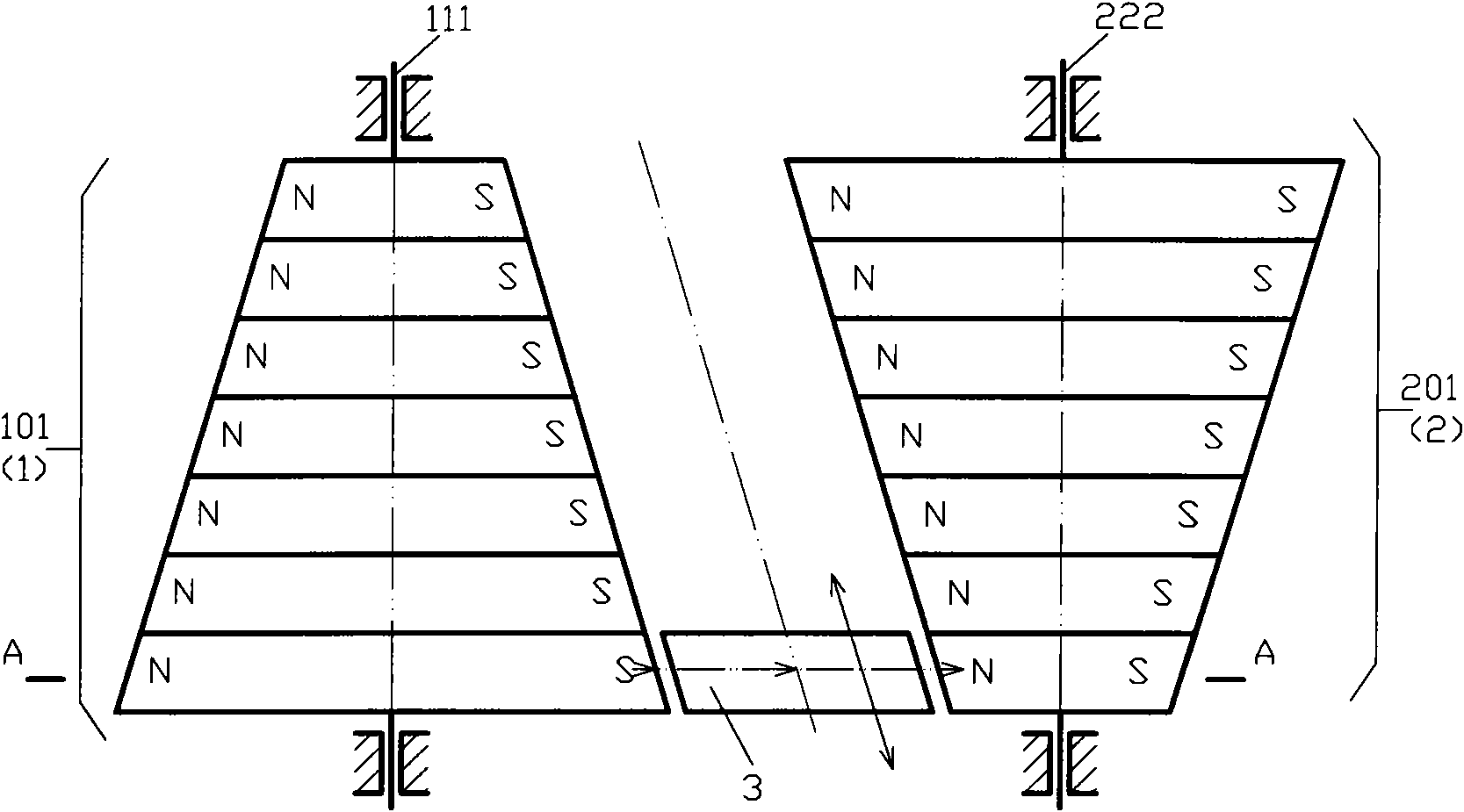

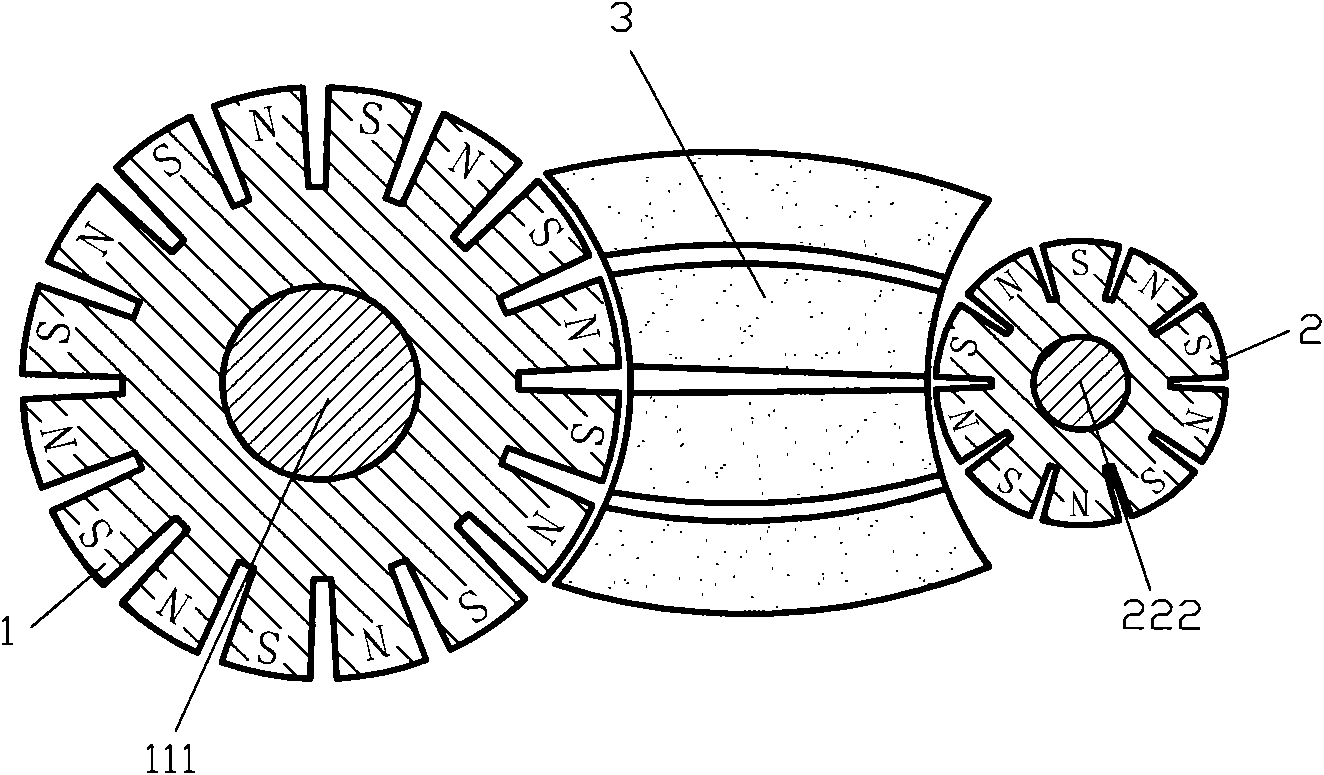

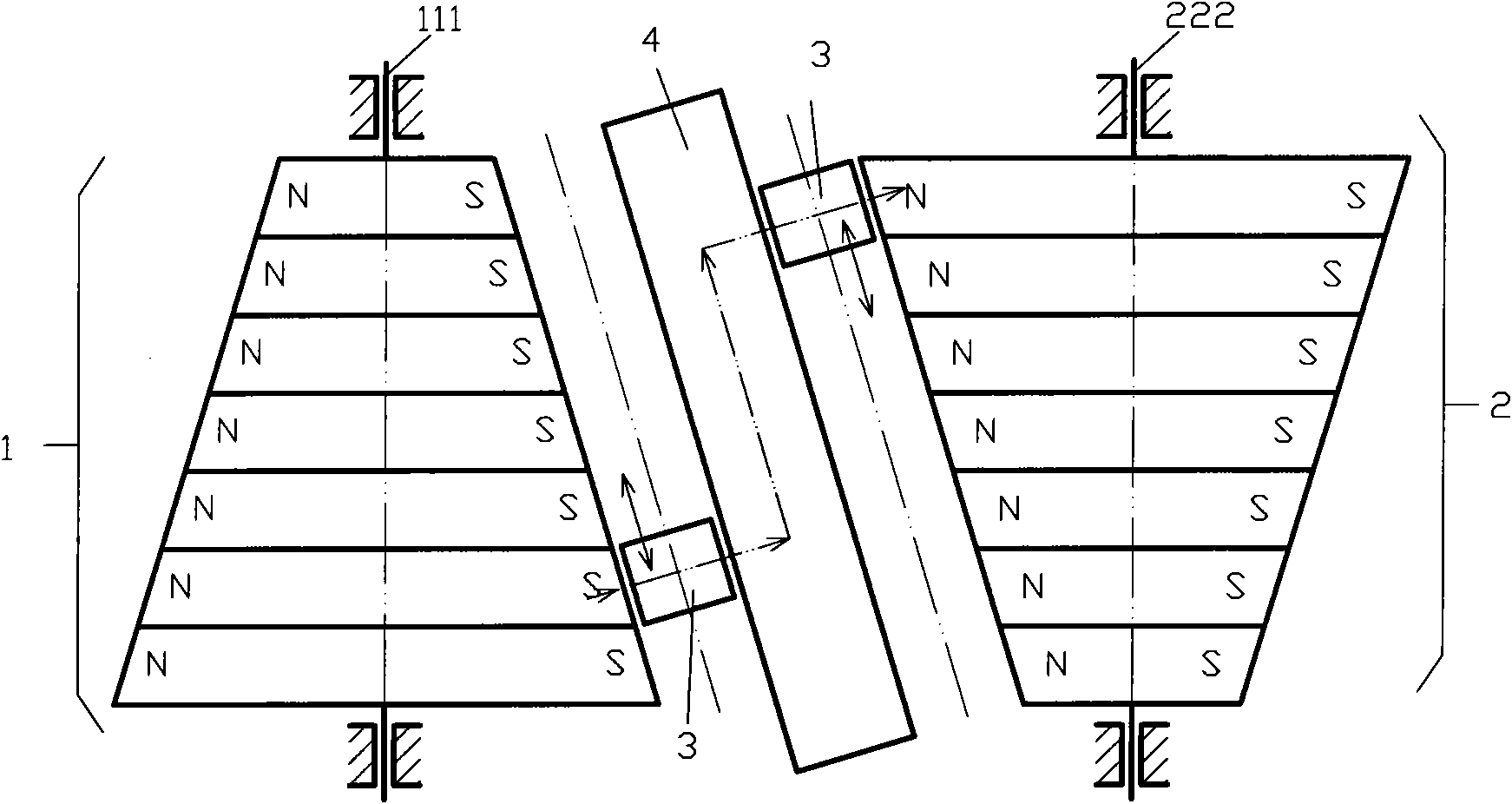

Magnetic gear shifting mechanism

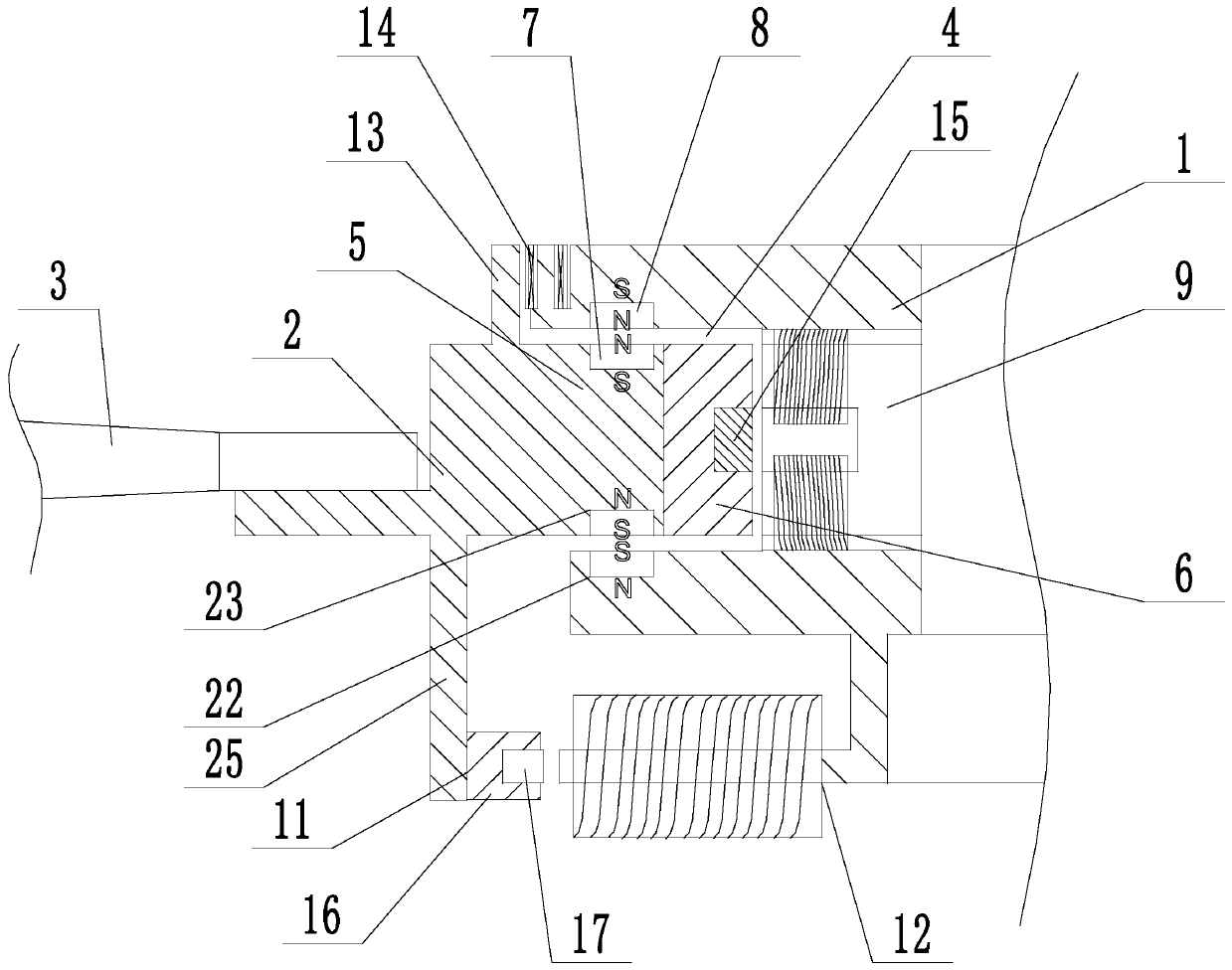

The invention discloses a magnetic gear shifting mechanism which comprises a first magnetic gear set and a second magnetic gear set. The first magnetic gear set comprises N magnetic gears coaxially arranged, the second magnetic gear set comprises M magnetic gears coaxially arranged, and the sum of M and N is greater than or equal to 3; the diameters of the magnetic gears in the first magnetic gear set are equal, and the diameters of the magnetic gears in the magnetic gear set are different; and at least one moving magnetizer is arranged between the first magnetic gear set and the second magnetic gear set, and transfers the magnetic lines of force of certain magnetic gear of the first magnetic gear set to certain magnetic gear of the second magnetic gear set, and either of a shaft A of the first magnetic gear set and a shaft B of the magnetic gear set is set as a power input shaft, and the other one is set as a power output shaft. The magnetic gear shifting mechanism disclosed by the invention has the advantages of simple structure and low energy consumption, and does not need lubrication.

Owner:靳北彪

Pressure retaining valve used for automobile tire inflation and deflation system

InactiveCN104728500AGood reliabilityLow powerOperating means/releasing devices for valvesMultiple way valvesLubricationElectromagnetic coil

The invention discloses a pressure retaining valve used for an automobile tire inflation and deflation system. The pressure retaining valve comprises a valve deck, a valve body, a valve seat, a first conical spring, a membrane piece, a gasket, a first O-shaped ring, a silencer, a nozzle, a rubber blanket, a second conical spring, a second O-shaped ring, a movable iron core, a stationary iron core, a third O-shaped ring, a wiring harness plug and an electromagnetic coil; the valve deck is installed on the valve body, the valve seat is installed at the bottom of the valve body, the membrane piece is installed below the valve deck, the first conical spring is installed at the position of the membrane piece, the gasket is installed below the membrane piece, the movable iron core is installed below the nozzle, the second conical spring is installed at the position of the nozzle, the rubber blanket is installed at the top of the movable iron core, the stationary iron core is installed at the bottom of the movable iron core, and the silencer is communicated with the bottom of the stationary iron core through an air flue. According to the pressure retaining valve, the reliability is good, the membrane piece is adopted for controlling the opening and closing of a gas port, compared with a piston type valve, the durability is better, the high temperature resistance and the low temperature resistance are better, and no lubrication is needed; a solenoid valve is adopted for conducting pilot control to an air chamber over the membrane piece, the power is low, and the energy consumption is little.

Owner:湖北军缔悍隆科技发展有限公司

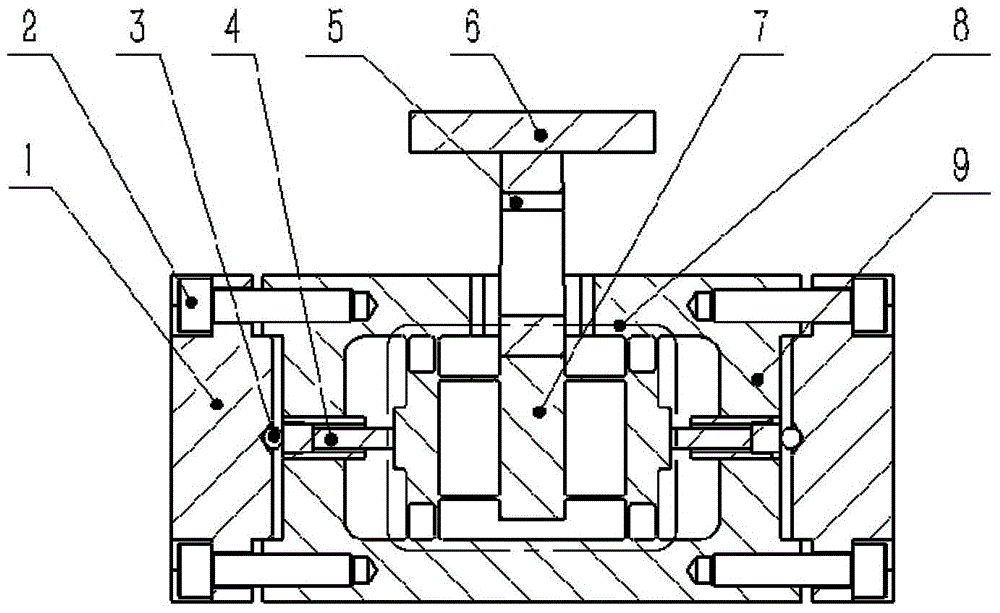

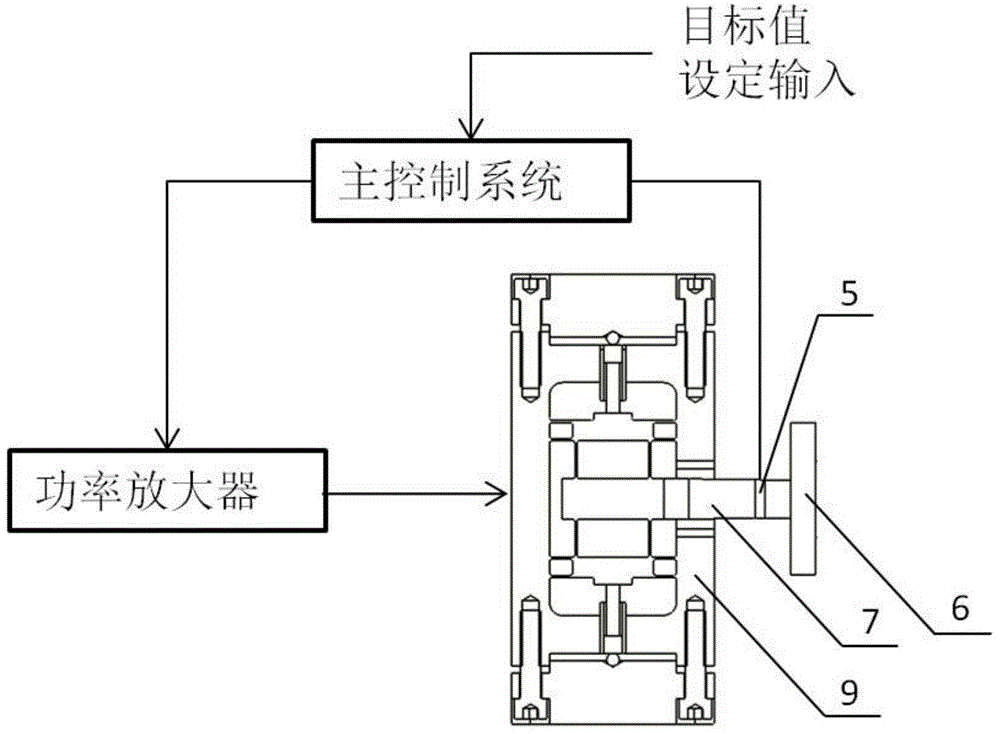

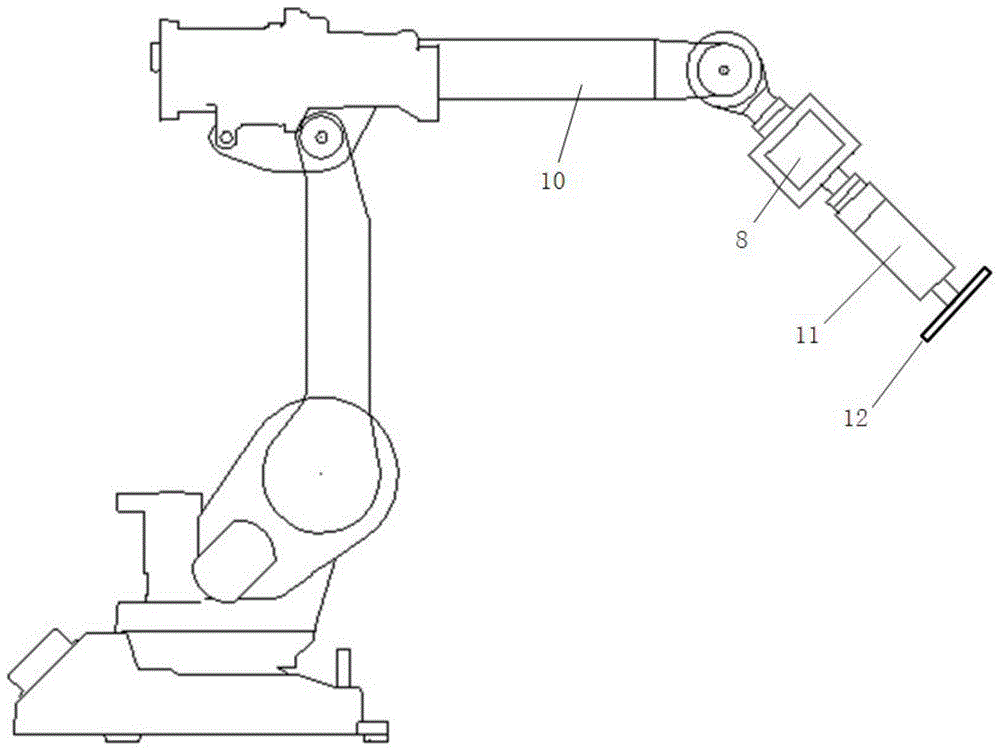

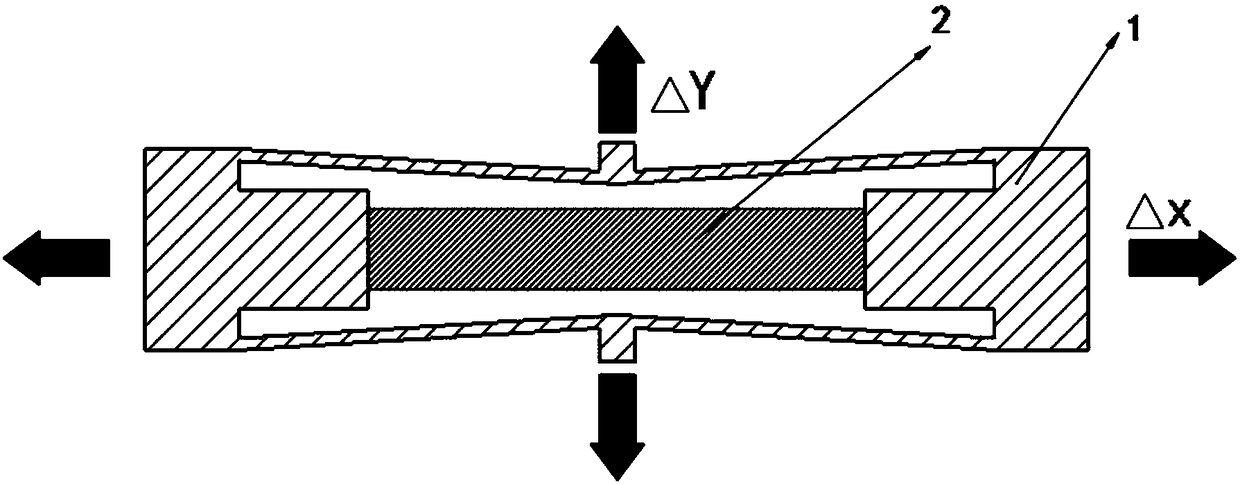

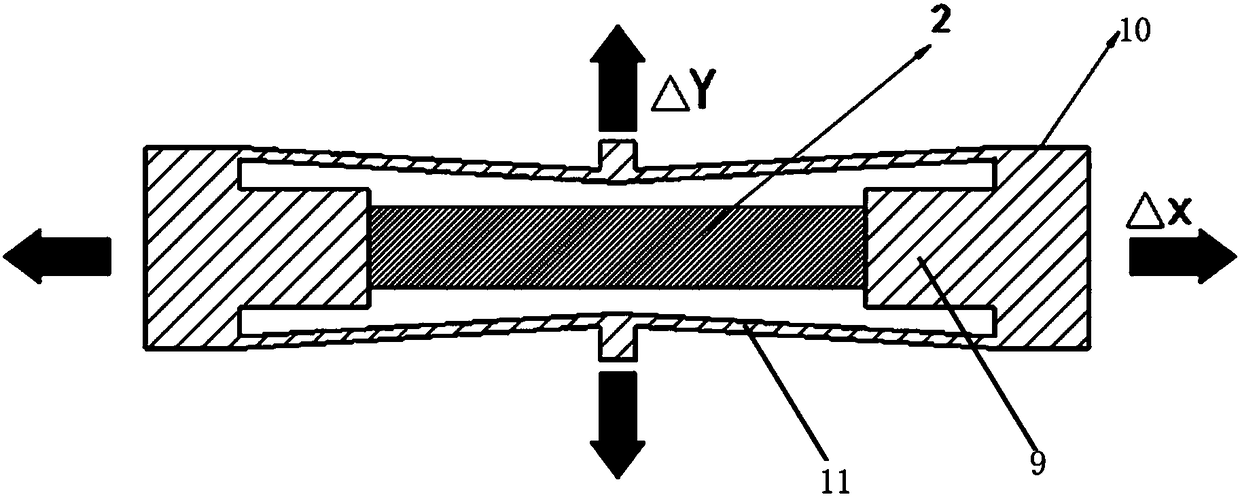

Force Control Module Based on Variable Stiffness Flexible Mechanism

ActiveCN104259991BHigh outputImprove dynamic response performanceGrinding machinesAutomatic grinding controlVariable stiffnessFlexible Mechanisms

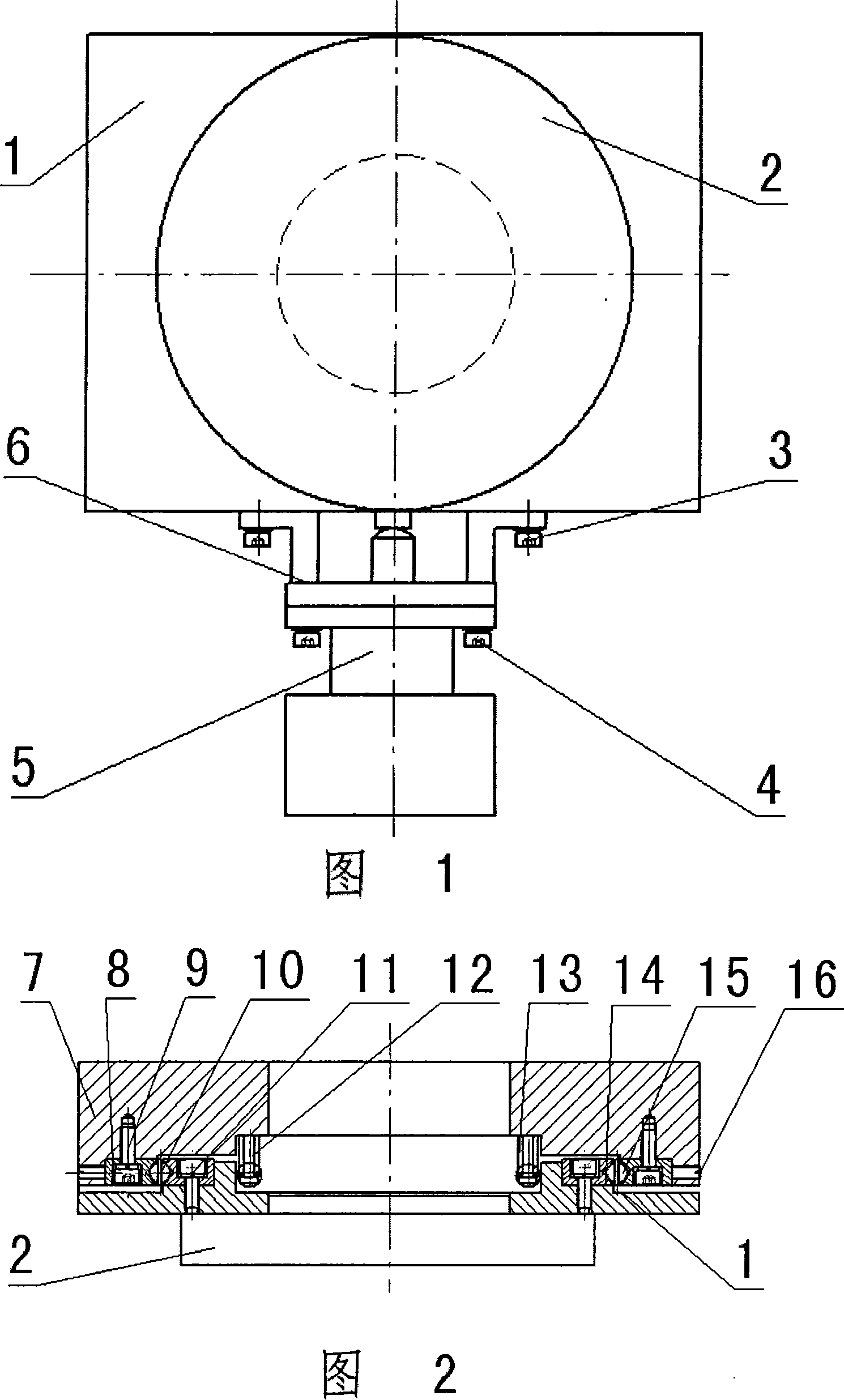

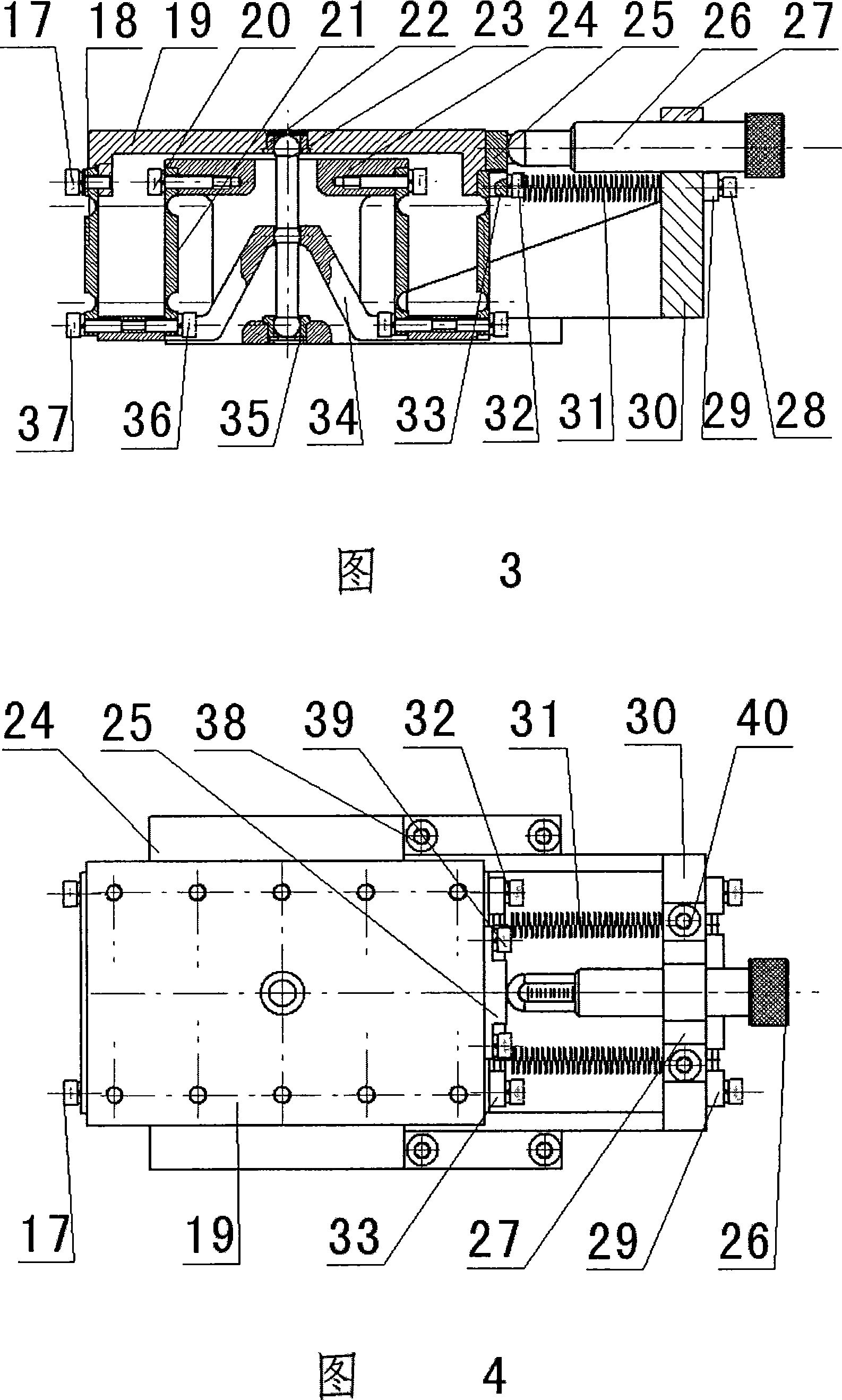

The invention provides a force control module based on a variable-rigidity flexible mechanism, and belongs to the technical field of machining. The module comprises a shell, cover plates covering the two ends of the shell, the flexible mechanism, piezoelectric actuators, pre-tightening steel balls and a sensor. The flexible mechanism is arranged between the two cover plates of the shell, the piezoelectric actuators are arranged between the two ends of the flexible mechanism and the cover plates respectively, the pre-tightening steel balls are arranged between the cover plates and the piezoelectric actuators, and the sensor is arranged at the output end of the flexible mechanism. In the contact type operation process, rigidity is actively variable, and contact force exerted on an object and displacement of an executor can be controlled independently. The force control module has high precision and high dynamic reaction performance, and the high-performance execution mechanism can serve as an additional module to provide high-performance actions and direct force control ability to a traditional position control system.

Owner:宏阔(南通)智能装备有限公司

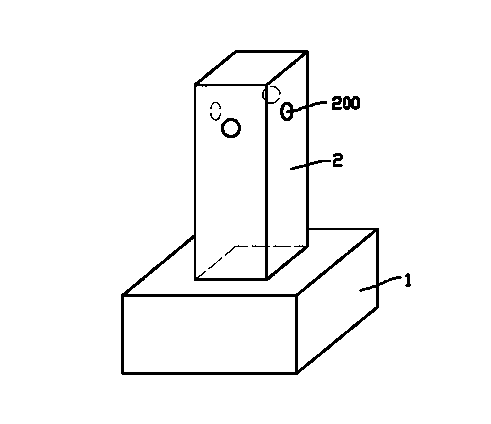

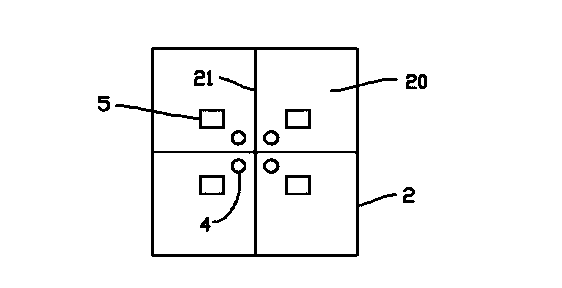

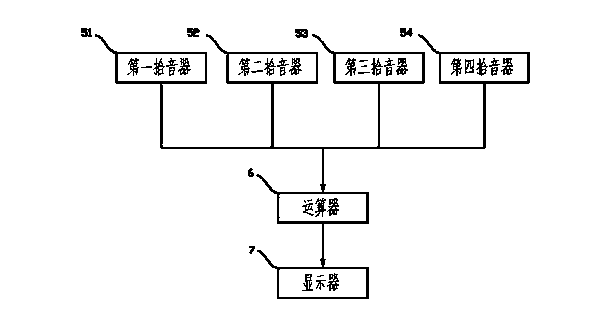

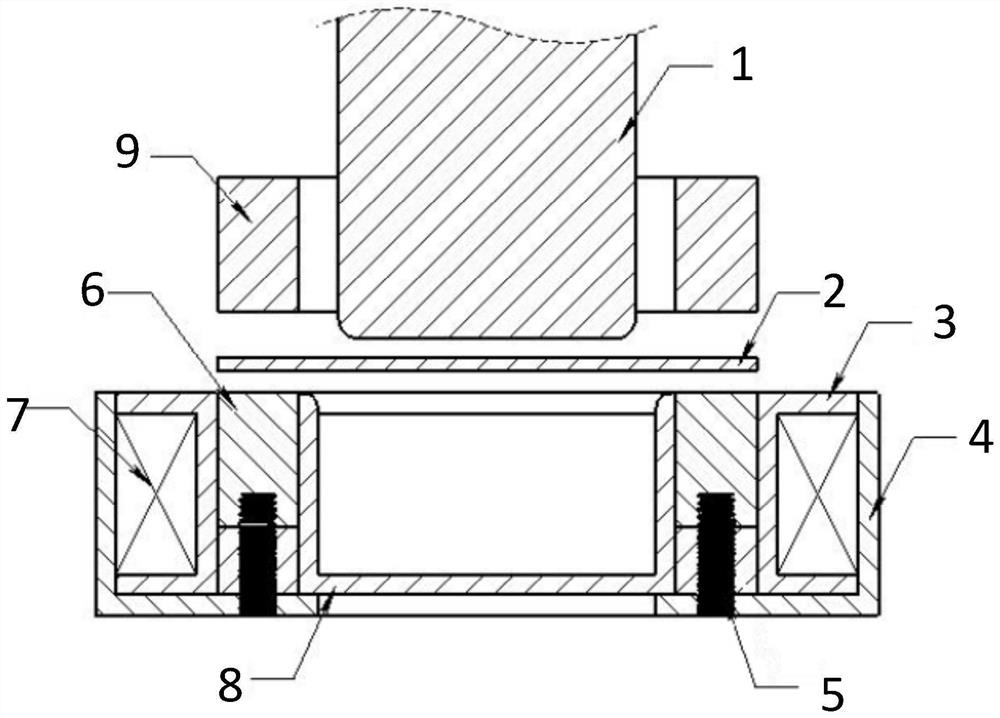

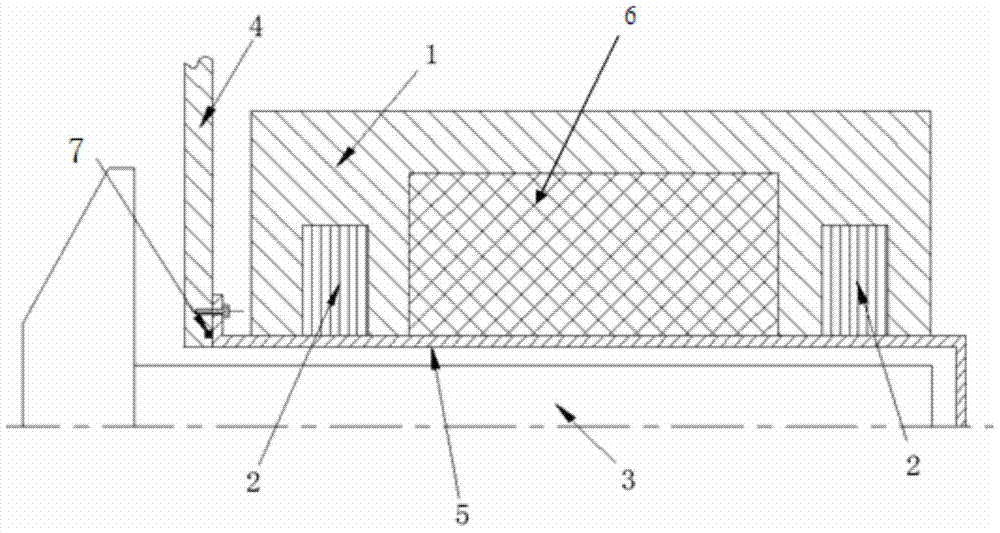

Whistle analysis type wind power monitor

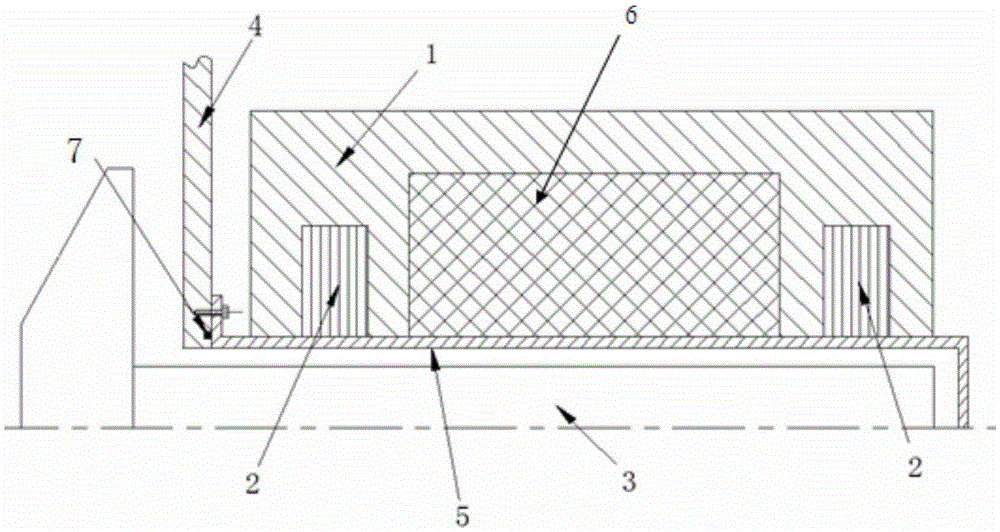

InactiveCN103675336ANo lubrication requiredGuaranteed monitoring accuracyIndication/recording movementFluid speed measurementDisplay deviceEngineering

The invention provides a whistle analysis type wind power monitor. The whistle analysis type wind power monitor comprises a base, wherein a fixed cuboid column is arranged on the top of the base in an extension mode, an air inlet hole is formed in each of the four side faces of the cuboid column, the air inlet holes are formed in the positions with the equal horizontal heights, the portion, arranged inside the cuboid column, of each air inlet hole is connected with a flow guiding pipe, each flow guiding pipe is connected with a whistle, a sound pick-up is assembled on each whistle in a matched mode, the sound pickups are electrically connected with a common arithmetic unit, the arithmetic unit calculates the wind direction and the wind speed according to audio signals picked up by the sound pickups, and the monitoring result is sent to a display and is displayed by the display. The whistle analysis type wind power monitor can resist severe weather environments, and cannot be easily damaged, and high measurement accuracy can be kept for a long time.

Owner:SUZHOU FENGZHIHUO DIGITAL TECH

Die blank holder device and application method thereof

PendingCN112517726AAvoid wrinklingThe workpiece is evenly stressedShaping toolsMetal-working feeding devicesMagnetoMagnet

The invention discloses a die blank holder device and an application method thereof. The die blank holder device comprises a shell and a die body. The die body comprises a male die, a female die, a magneto-rheological elastomer blank holder, an excitation coil, a coil framework and a permanent magnet. The excitation coil is wound on the coil framework; the permanent magnet is fixedly arranged in the coil framework; the magneto-rheological elastomer blank holder is arranged in the coil framework and is fixedly connected with the permanent magnet; the female die is arranged at the inner side ofthe magneto-rheological elastomer blank holder, and the male die is connected with a stamping mechanism to stamp a plate on the female die; the excitation coil generates a magnetic field after being electrified; and the size of the magnetic field is controlled, and the rigidity of the magneto-rheological elastomer blank holder is adjusted so as to control the blank holding force and the distance between the magneto-rheological elastomer blank holder and the plate. By means of the material characteristics of the magneto-rheological elastomer, the blank holder force in deep drawing forming is controlled, a workpiece is prevented from being broken in deep drawing forming, the workpiece forming rate is increased, lubrication is not needed, the cost is reduced, the structure is compact, and thepracticability is high.

Owner:SHANGHAI APPLIED TECHNOLOGIES COLLEGE +2

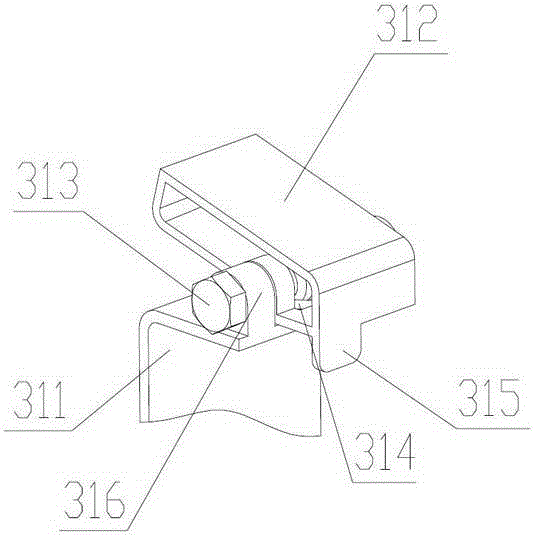

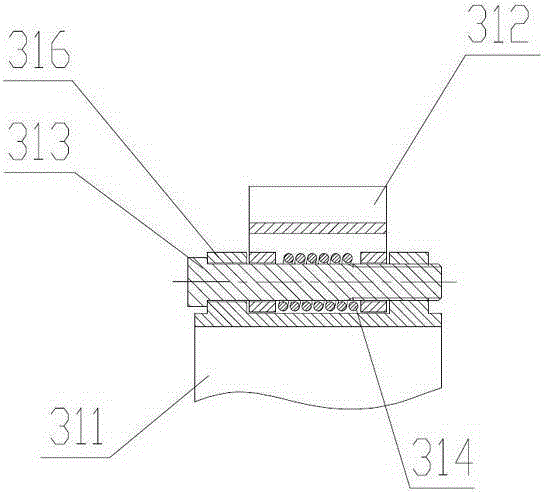

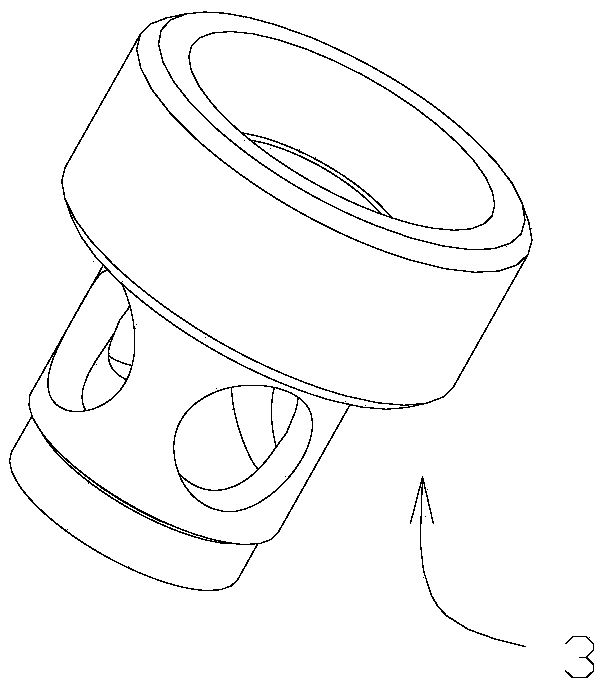

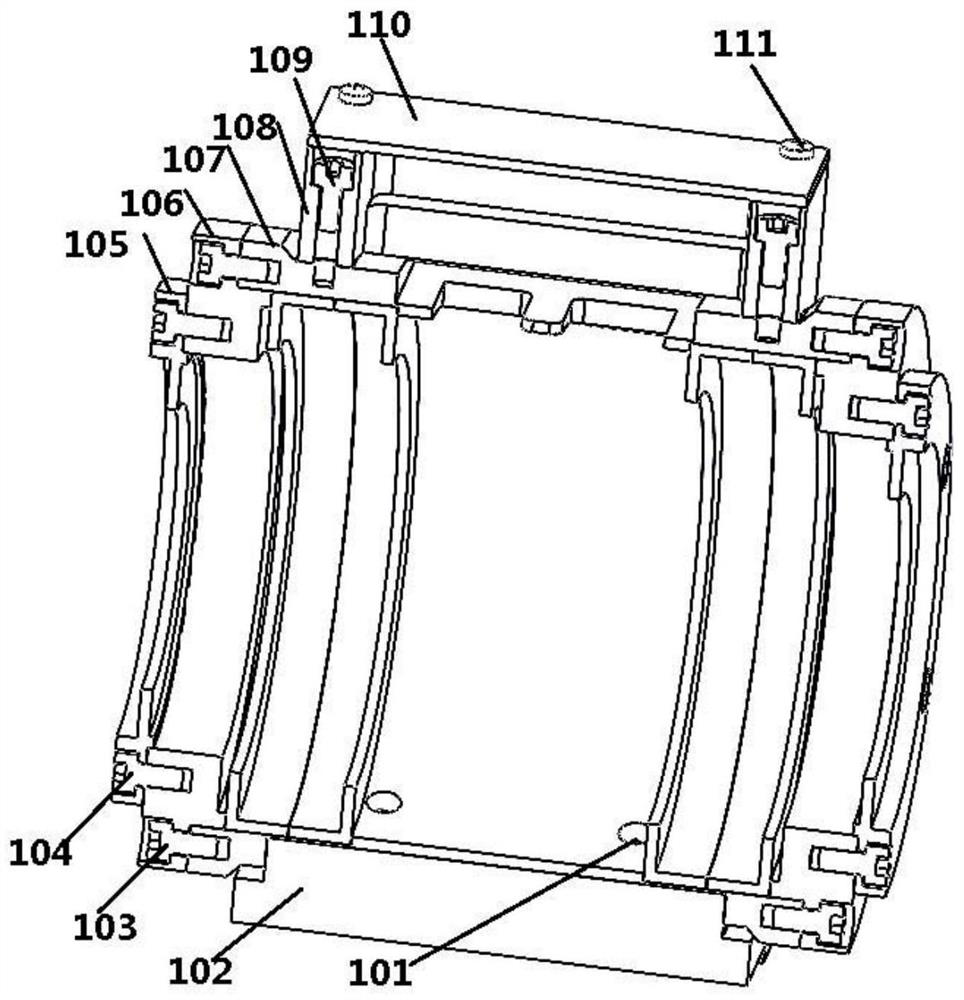

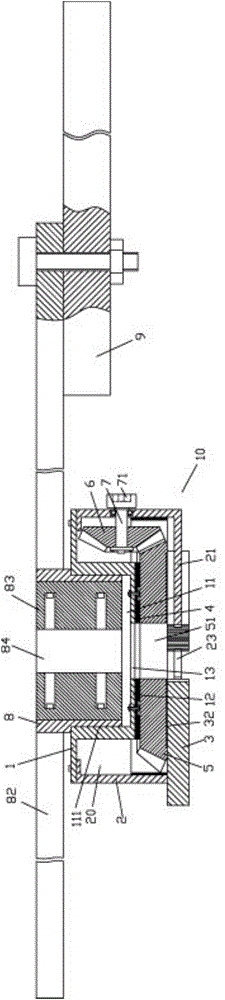

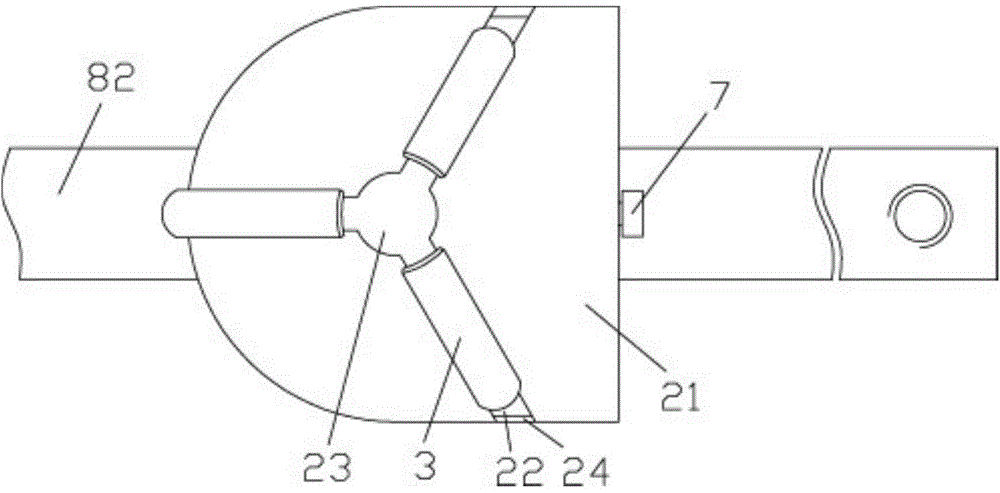

Optical fiber preformrod collet

PendingCN109095766AReduce labor intensityImprove general performanceGlass making apparatusIntensity controlEngineering

The invention discloses an optical fiber preformrod collet. The optical fiber preformrod collet comprises a preformrod fixing seat, a heat dissipation element and a connecting element, wherein the preformrod fixing seat comprises a clamping element and an opening-closing lining, the external surface of the opening-closing lining is jointed with the inner surface of the clamping element, and the inner surface of the opening-closing lining is jointed and connected with the external surface of the optical fiber preformrod; and the upper end of the clamping element is in threaded connection with the lower end of the heat dissipation element, the upper end of the heat dissipation element is in threaded connection with the lower end of the connecting element, and the upper end of the connectingelement is used for being connected with a three-jaw chuck. According to the optical fiber preformrod collet disclosed by the application of the invention, two steps of clamping and loading can be separately performed, so that the labor intensity of workers can be reduced, and the technological level can be increased; and the problems of difficult intensity control, difficult heat dissipation, inconvenient operation and the like in a three-jaw chuck type method can be solved.

Owner:NANJING CHUNHUI SCI & TECH IND

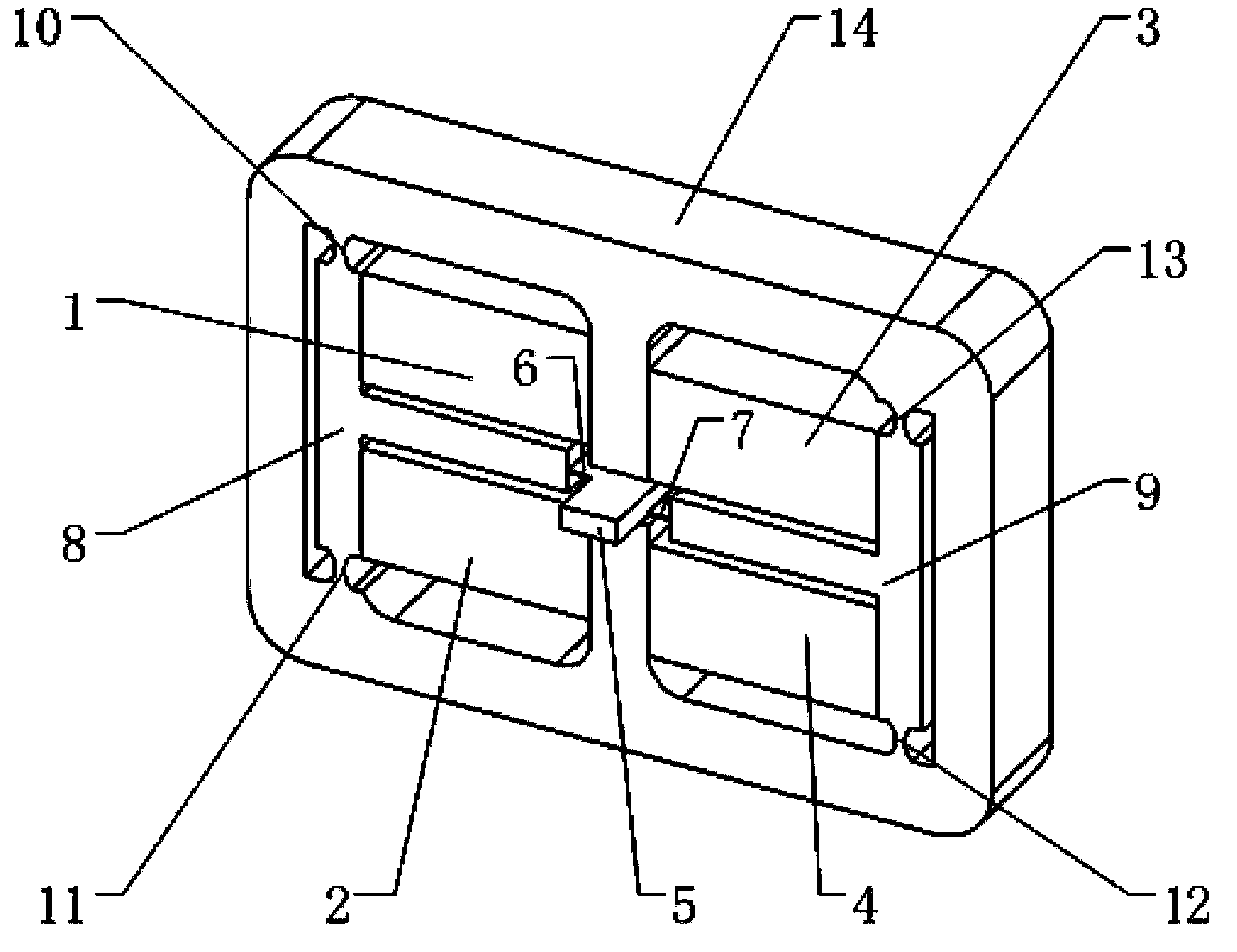

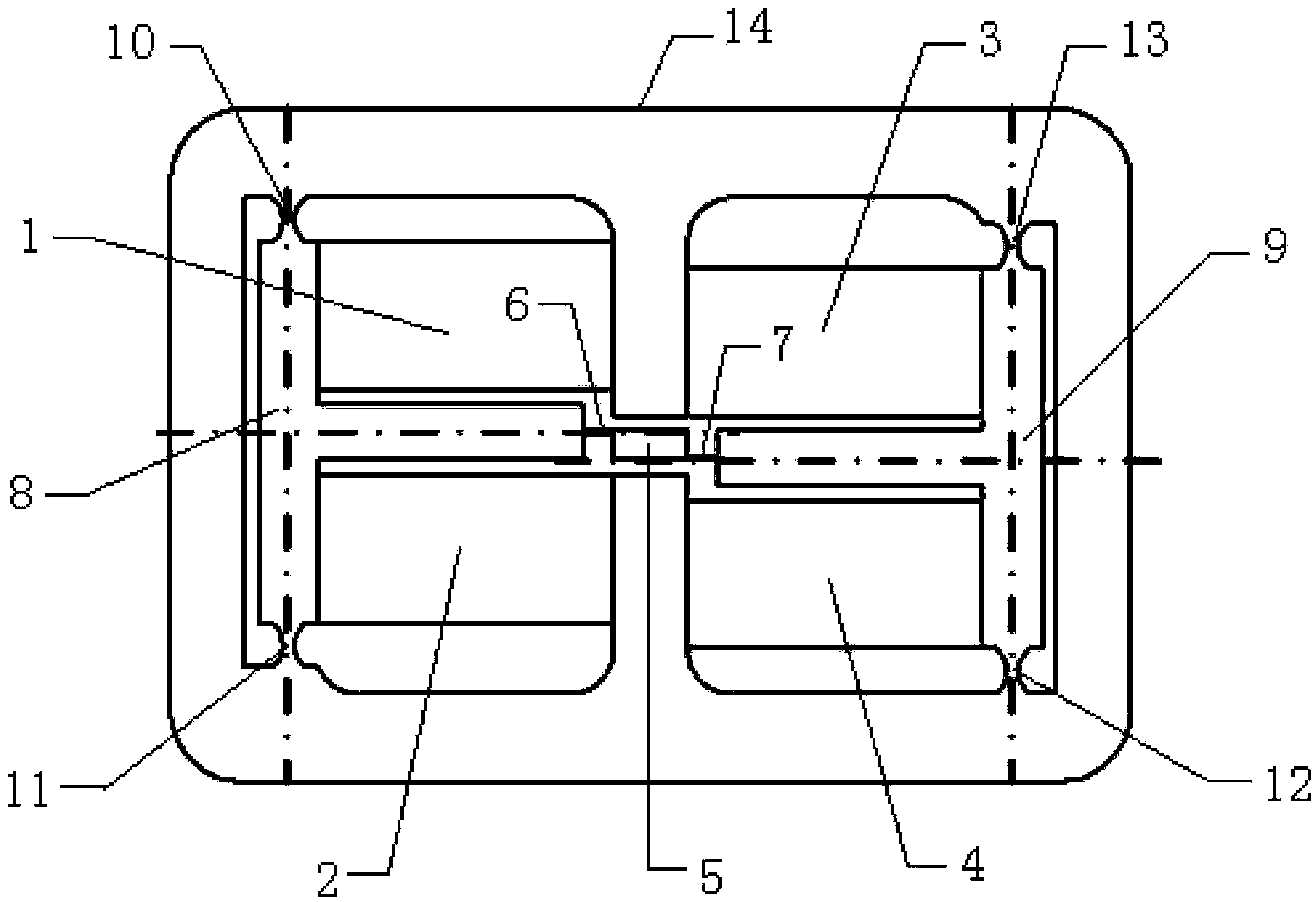

Detachable pipe wrench

A detachable pipe wrench comprises a wrench body. The wrench body comprises an upper shell and a lower shell. A gear cavity is formed inside the upper shell and the lower shell. The middle of the upper shell is concaved downwards to form a circular groove, a circular through hole is formed in an upper bottom plate of the circular groove, three long through grooves and an inserting hole are formed in a bottom plate of the lower shell, three notches are formed in the bottom of the side wall of the lower shell, the notches are communicated with the tail ends of the long through grooves, long-strip-shaped grooves are formed in the two side walls of clamping blocks, and the two side walls of the long through grooves are inserted into the long-strip-shaped grooves in a sleeved mode. A Teflon layer is fixed on the lower bottom face of the upper bottom plate, the gear cavity is internally provided with a main bevel gear and a drive bevel gear which are meshed with each other, and the main bevel gear is arranged between the Teflon layer and the clamping blocks. The detachable pipe wrench is simple in structure, a user can hold two wrench arms to carry out double-hand operation by hands, efficiency is improved, the three clamping blocks and a circular elastic block are used for carrying out further clamping, the clamping effect is improved, and a pipe is prevented from skidding when rotating.

Owner:SUZHOU QISHUO INFORMATION TECH CO LTD

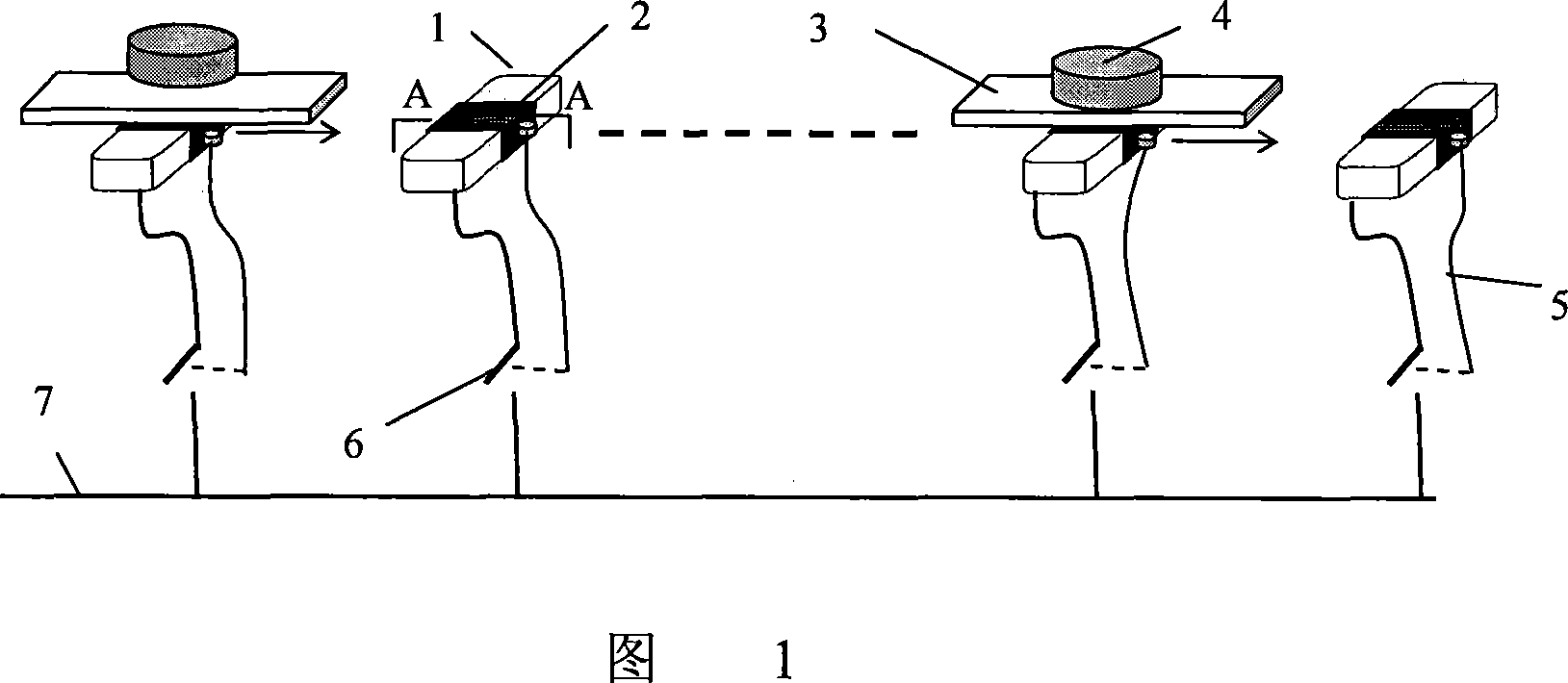

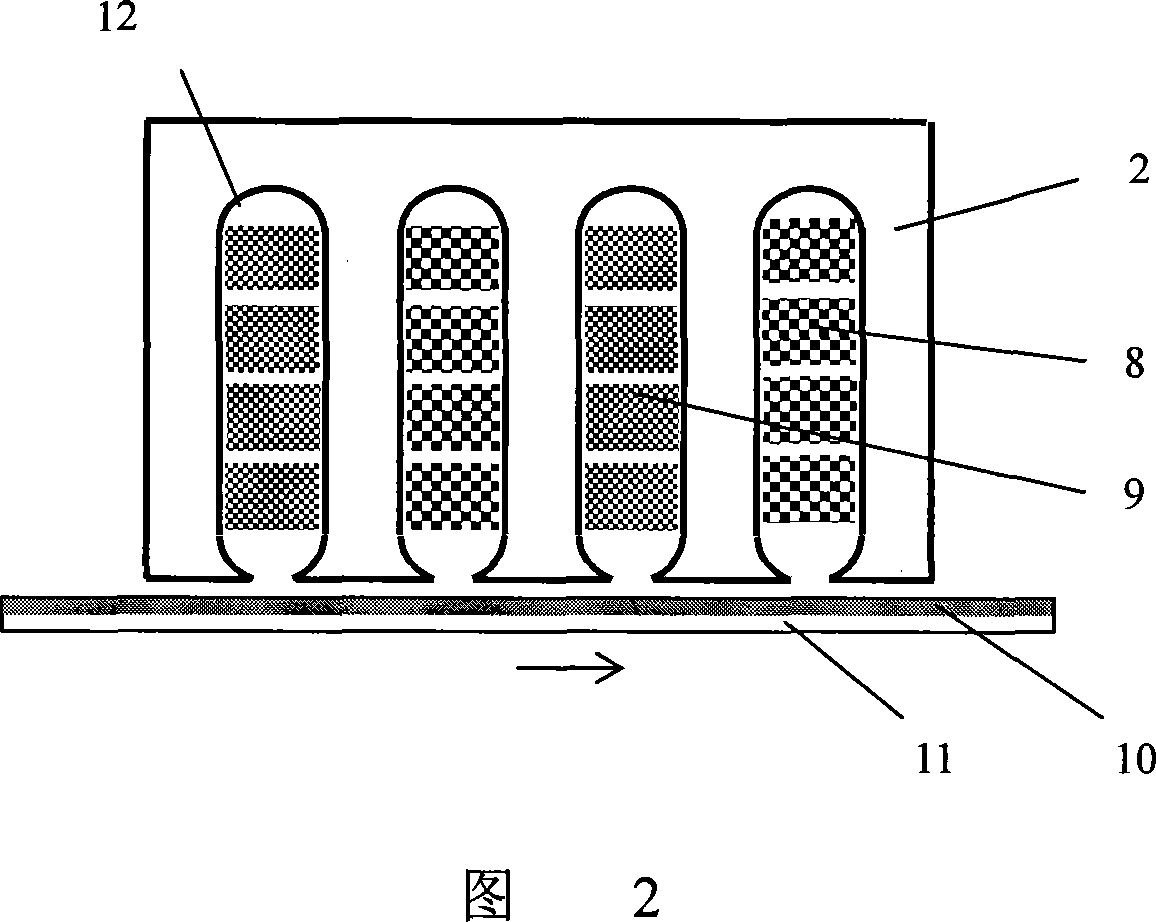

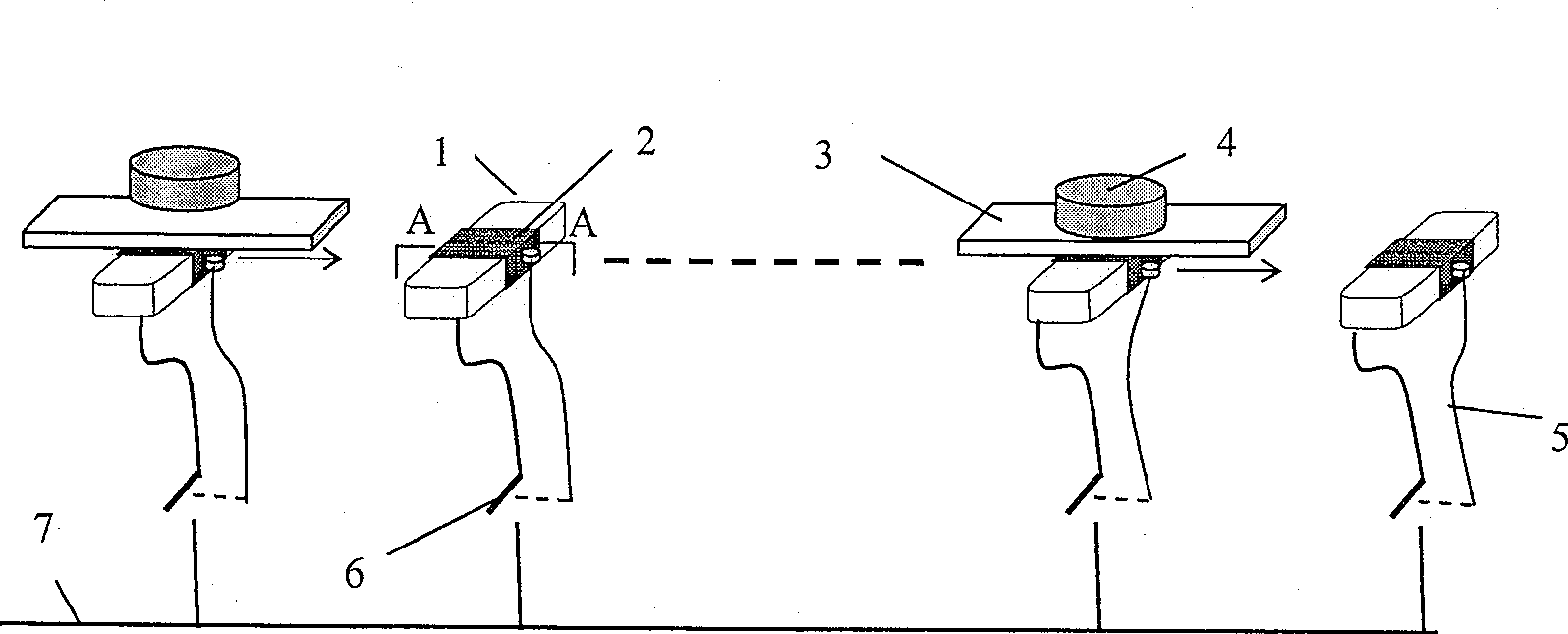

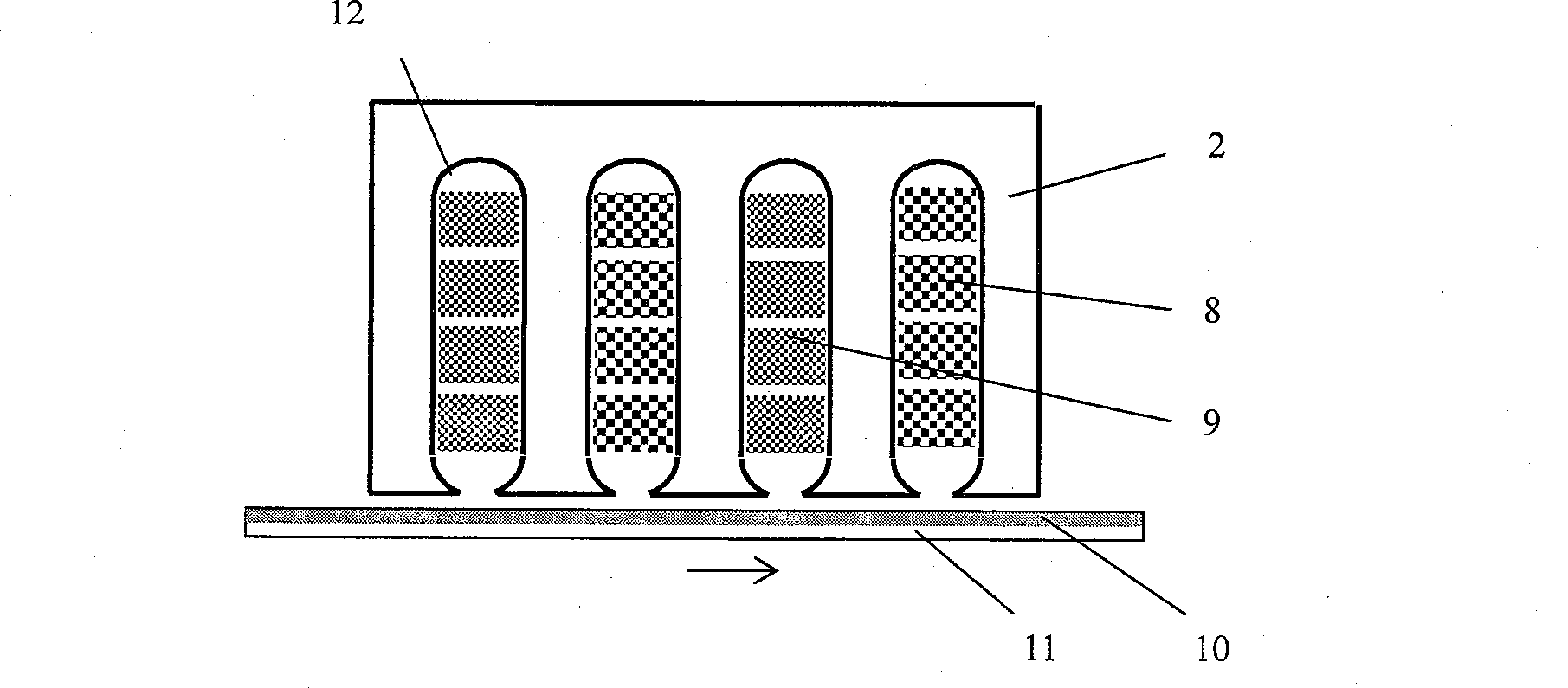

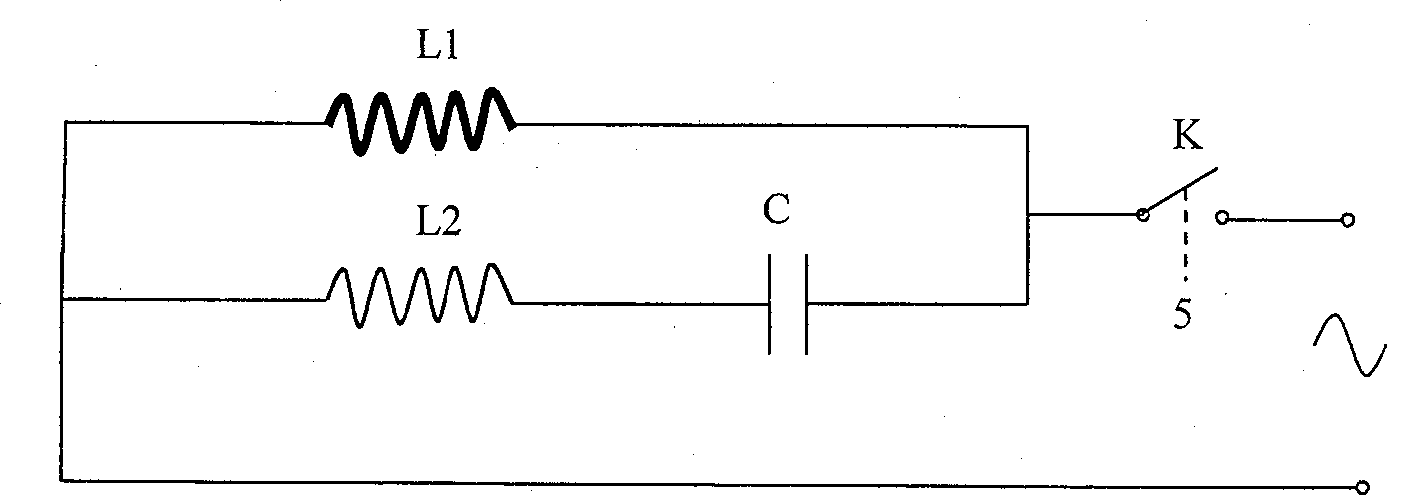

A deep slot single-phase capacitance operation linear motor

The present invention discloses a deep slot type linear electric motor running with single-phase capacitance. The electric motor includes two levels: the primary and the combined secondary, wherein the primary unit is positioned along the transmitting line in an interval distribution modus. The characteristics are: 1) four deep grooves are positioned on each primary iron core, wherein the ratio of the highness and the width of the groove is 6~12 and the windings are layered in the groove; 2) the primary main winding is unsymmetrical with the secondary winding which is connected to a capacitor C in series, and the turn number is not identical to the line radius, and the main winding is connected to the secondary winding which is connected to a capacitor C in series in parallel and is connected to the electric power source gate through a controllable switch; 3) the secondary winding is in a single phase running relative to the primary and has a cuprum-iron compound structure. The linear electric motor drives the load directly and has a simple structure, a small starting current, a low noise, a high efficiency and a high reliability. The single-phase running of the linear electric motor satisfies the requirement of the physical distribution conveying line and is adaptable for the production and the situation in which the physical distribution line in commercial use is running in a straight line of any types of linear electric motors and is especially adaptable for the physical distribution lines in supermarket or medicine use of common people.

Owner:ZHEJIANG UNIV

Non extensible guide precision displacement platform

InactiveCN101140810ASimple structural partsReduce manufacturing costInstrumental componentsEngineeringMechanical equipment

A precise mobile platform without guide is provided, which belongs to the technical field of mechanical equipment. The technical matters required to be solved is to provide a precise mobile platform without guide. The technical solution to solve the problem are composed of a movable table, a pullback spring, a driving mechanism, a base, a deformed plate, an upper bush, a proportional handspike, a move-down plate, a lower bush and other elements. The proportional handspike, a rigid straight bar with spherical surfaces at both ends and in the middle, is symmetrical distributed under the movable table to form a supporting structure. The base, deformed plate and the move-down plate form an internal parallelogram structure, while the move-down plate, lower bush and movable table shapes an external parallelogram structure. The two composite parallelogram structures guarantee an only rectilinear translation motion forward and backward without seesaw motion when the movable table is in motion, thus to realize a high precision rectilinear motion of the functional elements on the mobile platform.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

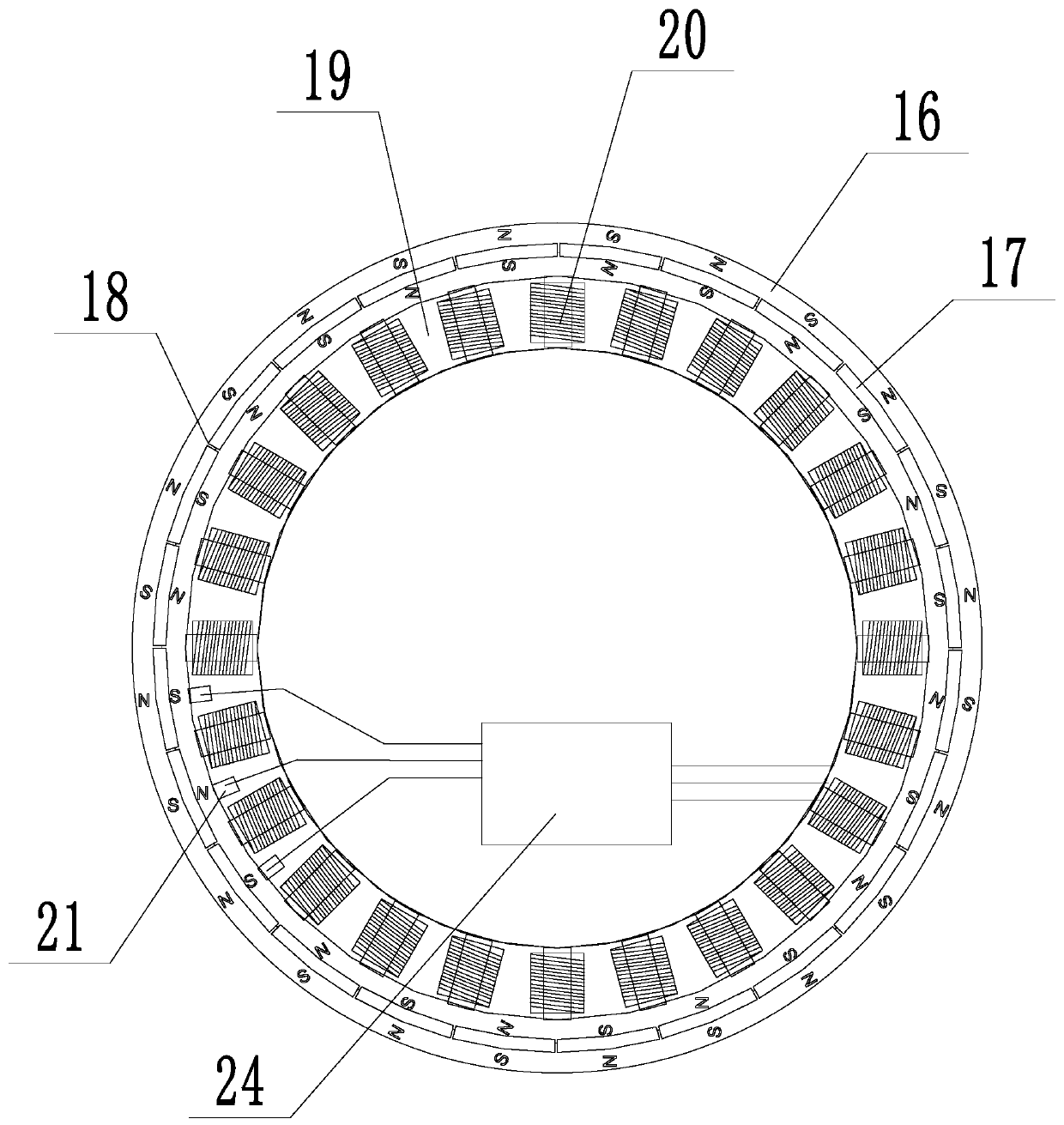

A large-diameter annular magnetic levitation motor and its control method

ActiveCN109713869BNo lubrication requiredNo mechanical wearDynamo-electric machinesMagnetic holding devicesControl systemMagnetic poles

Owner:ZHEJIANG AFO AVIATION SCI & TECH CO LTD

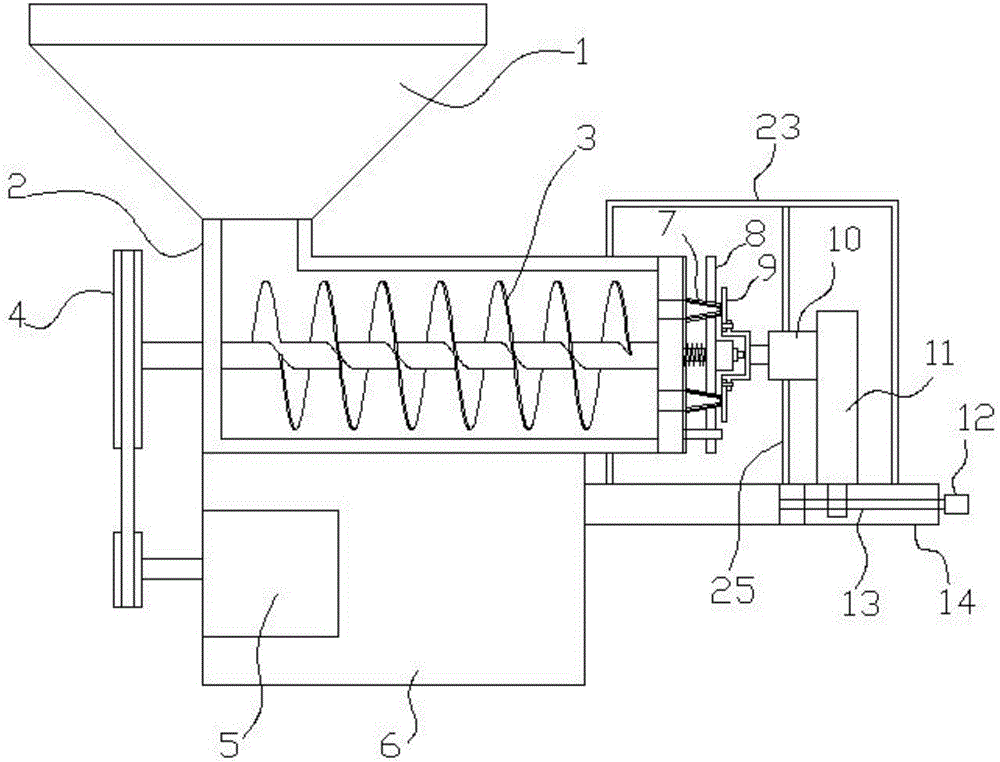

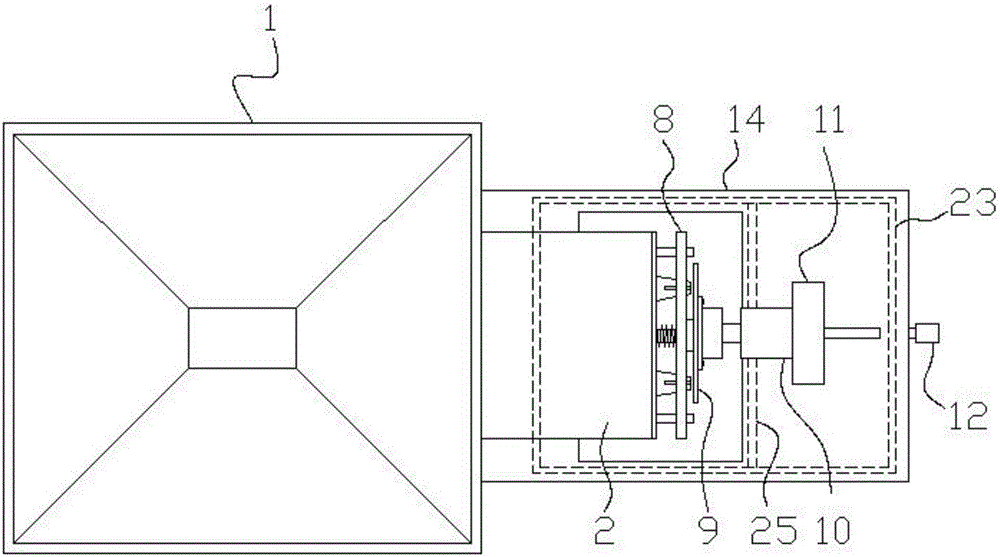

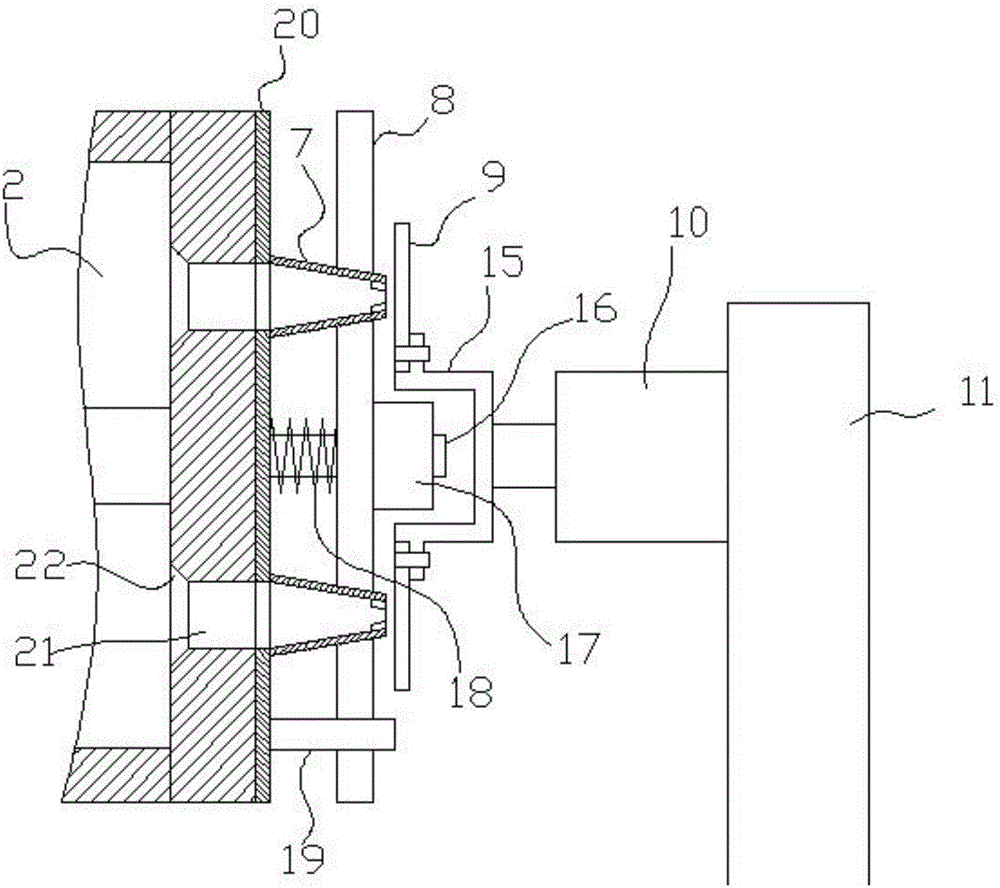

An extrusion cutting type multi-particle size adjustable granulator

ActiveCN106622022BLarge adjustment rangeEasy to adjustGranulation in rotating dishes/pansGranulation by material expressionPropellerAgricultural engineering

The invention discloses an extrusion cutting type multi-particle size adjustable granulating machine. The extrusion cutting type multi-particle size adjustable granulating machine comprises a stirring cylinder, wherein the stirring cylinder is arranged on a base, a spiral propeller is arranged in the stirring cylinder, and a material inlet hopper is arranged at the upper end of the stirring cylinder; the spiral propeller is connected with a propelling motor; a granulating disc is arranged at the front end of the stirring cylinder; conical granulating sleeves are uniformly arranged on the granulating disc, and are sheathed on an adjusting disc; a cutting tool disc is arranged at the front end of each conical granulating sleeve, and is fixedly arranged on a fixed disc; the fixed disc is connected with a cutting motor, and the cutting motor is arranged on a slide base; the slide base is connected with a screw rod in a bracket, and the bracket is connected with the base; an adjusting rotary button is arranged at the front end of the screw rod; each conical granulating sleeve is in a conical sleeve shape, and adjusting grooves are uniformly arranged at the front end of each conical granulating sleeve; mounting grooves are arranged on the inner walls of both sides of each adjusting groove; an arc-shaped movable plate is arranged in each mounting groove; outlet tool blades are uniformly arranged on the inner wall of the front end of each conical granulating sleeve. The extrusion cutting type multi-particle size adjustable granulating machine has the advantages that the quick and high-efficiency granulating function is realized, the granulating size can be adjusted, the adjusting range is wide, and the flexibility and convenience in use are realized.

Owner:湖南康易达绿茵科技有限公司

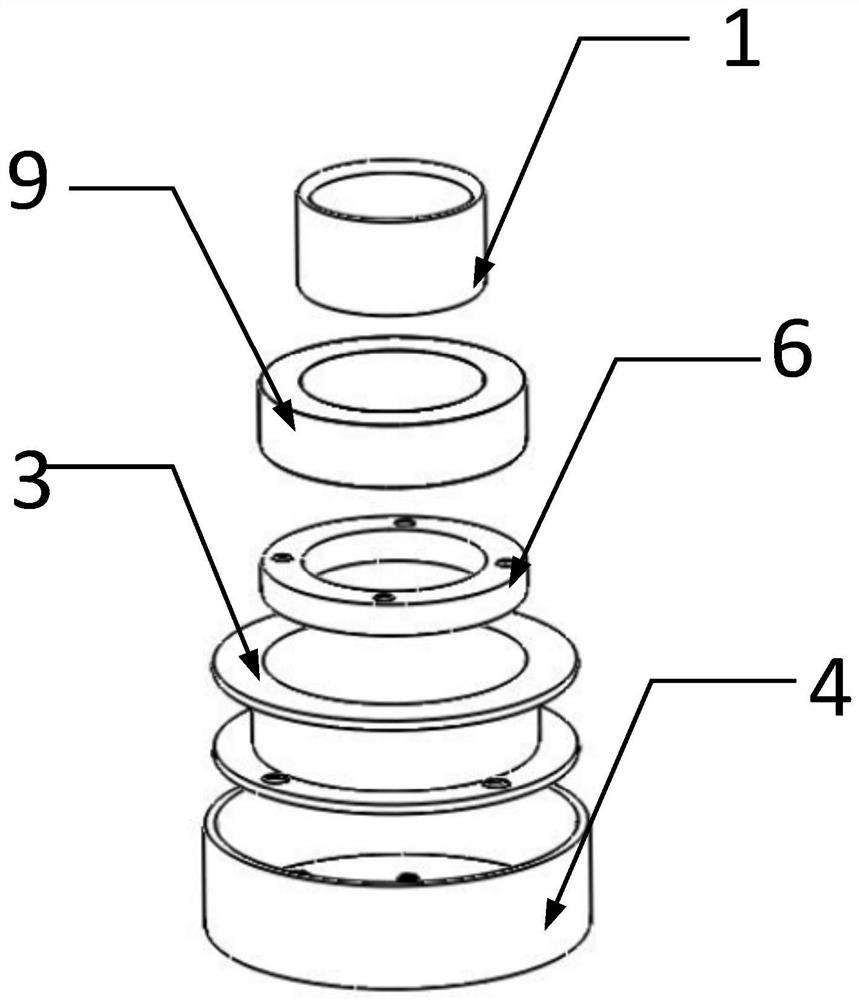

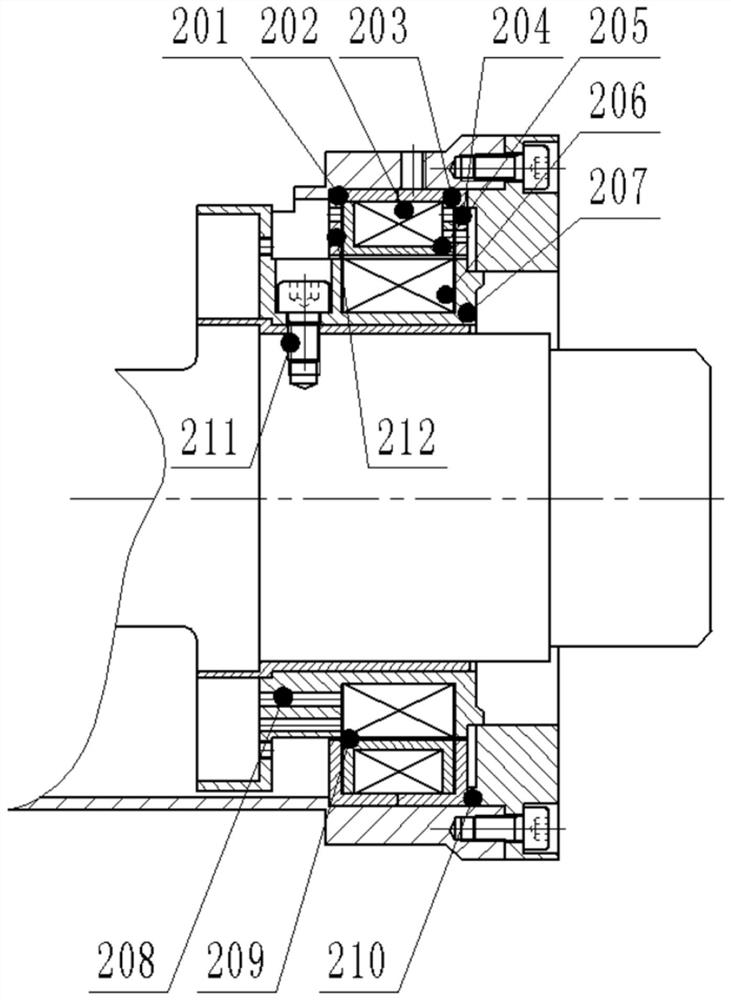

Magnetic suspension bearing isolation rotor structure

The invention discloses a magnetic suspension bearing isolation rotor structure which comprises a base, magnetic suspension bearings, a rotor and a stator, wherein the magnetic suspension bearings and the stator are supported on the base, and the rotor is arranged in the magnetic suspension bearings and the stator in a penetrating manner. The magnetic suspension bearing isolation rotor structure further comprises a fluid container and a sheath, wherein the sheath is in a bucket-shaped structure with one end opened and the other end sealed; the sheath is arranged between the magnetic suspension bearings and the rotor and between the stator and the rotor in a penetrating manner; the open end of the sheath stretches out of the base and is connected with the fluid container; an inner cavity of the sheath is communicated with an inner cavity of the fluid container; and the left end of the rotor stretches into the inner cavity of the fluid container. The magnetic suspension bearing isolation rotor structure is good in sealing effect, long in service life and simple in structure; the sealed magnetic suspension bearing isolation rotor structure is free from limitation of the rotating speed and the linear surface speed of the rotor; except the rotor and the sheath, the other parts are free from the influence from a sealed fluid, and have no special requirements on structures and performances of used materials; and the magnetic suspension bearings require no lubrication.

Owner:NANJING CIGU TECH CORP LTD

Magnetic suspension bearing dynamic torque sensor

ActiveCN106644224BIncrease dynamic rotation speedReduce noiseForce sensorsMagnetic bearingTransducer

The invention discloses a magnetic suspension bearing dynamic torque sensor, which includes a frame structure part, an electric drive part, a rotating shaft sensing part, a magnetic suspension bearing part and a signal processing part, the rotating shaft sensing part includes an elastic body shaft and a resistance strain gauge, and the elastic body shaft The middle section is provided with a ring-shaped groove for installing resistance strain gauges. The electric drive part includes two sets of transformer electromagnetic induction units, each of which includes a stator and a rotor. The two rotors are symmetrically fixed on the elastomer shaft through the ring-shaped groove. , the two stators are respectively fixed on the frame structure part at positions corresponding to their respective rotors, the magnetic suspension bearing part includes two sets of magnetic suspension bearings, which are symmetrically installed outside the two sets of transformer electromagnetic induction units, and the rotors of each set are fixed on the The stators of each group are fixed on the frame structure part on the elastomer shaft, the structure is easy to disassemble, and the rotating speed and torque can be easily measured to reduce accidents.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

A helicopter rigid rotor hub

ActiveCN112046739BHigh frequencyRealize variable distance controlPropellersRotocraftRigid rotorClassical mechanics

A helicopter rigid rotor hub, a plurality of pitch-variable arm modules are arranged around the center piece module; blades are fixed on the pitch-variable arm modules; the pitch-variable arm modules include blade mounts, outer radial lamination elastic bearings, Laminated Elastomeric Bearing, Inner Radial Laminated Elastomeric Bearing; The blade is fixed on the blade mount; Outer Radial Laminated Elastomeric Bearing and Inner Radial Laminated Elastomeric Bearing The outer ring is fixed on the blade mounting seat, and the outer ring is fixed on the center piece module; the inner ring of the inner radially laminated elastic bearing is fixed on the blade mounting seat, and the outer ring is fixed on the center piece module; the thrust lamination elastic bearing The bearing is composed of axially stacked laminated elastic bearings, the inner side of the thrust laminated elastic bearing is fixed on the blade mount, and the outer side is fixed on the center piece module; the axes of the three elastic bearings are collinear. The propeller hub of the present invention has the characteristics of high service life, no lubrication, no wear, no maintenance and the like.

Owner:NO 60 RES INST OF GENERAL STAFF DEPT PLA

Magnetic Suspension Bearing Isolation Rotor Structure

The invention discloses a magnetic suspension bearing isolation rotor structure which comprises a base, magnetic suspension bearings, a rotor and a stator, wherein the magnetic suspension bearings and the stator are supported on the base, and the rotor is arranged in the magnetic suspension bearings and the stator in a penetrating manner. The magnetic suspension bearing isolation rotor structure further comprises a fluid container and a sheath, wherein the sheath is in a bucket-shaped structure with one end opened and the other end sealed; the sheath is arranged between the magnetic suspension bearings and the rotor and between the stator and the rotor in a penetrating manner; the open end of the sheath stretches out of the base and is connected with the fluid container; an inner cavity of the sheath is communicated with an inner cavity of the fluid container; and the left end of the rotor stretches into the inner cavity of the fluid container. The magnetic suspension bearing isolation rotor structure is good in sealing effect, long in service life and simple in structure; the sealed magnetic suspension bearing isolation rotor structure is free from limitation of the rotating speed and the linear surface speed of the rotor; except the rotor and the sheath, the other parts are free from the influence from a sealed fluid, and have no special requirements on structures and performances of used materials; and the magnetic suspension bearings require no lubrication.

Owner:NANJING CIGU TECH CORP LTD

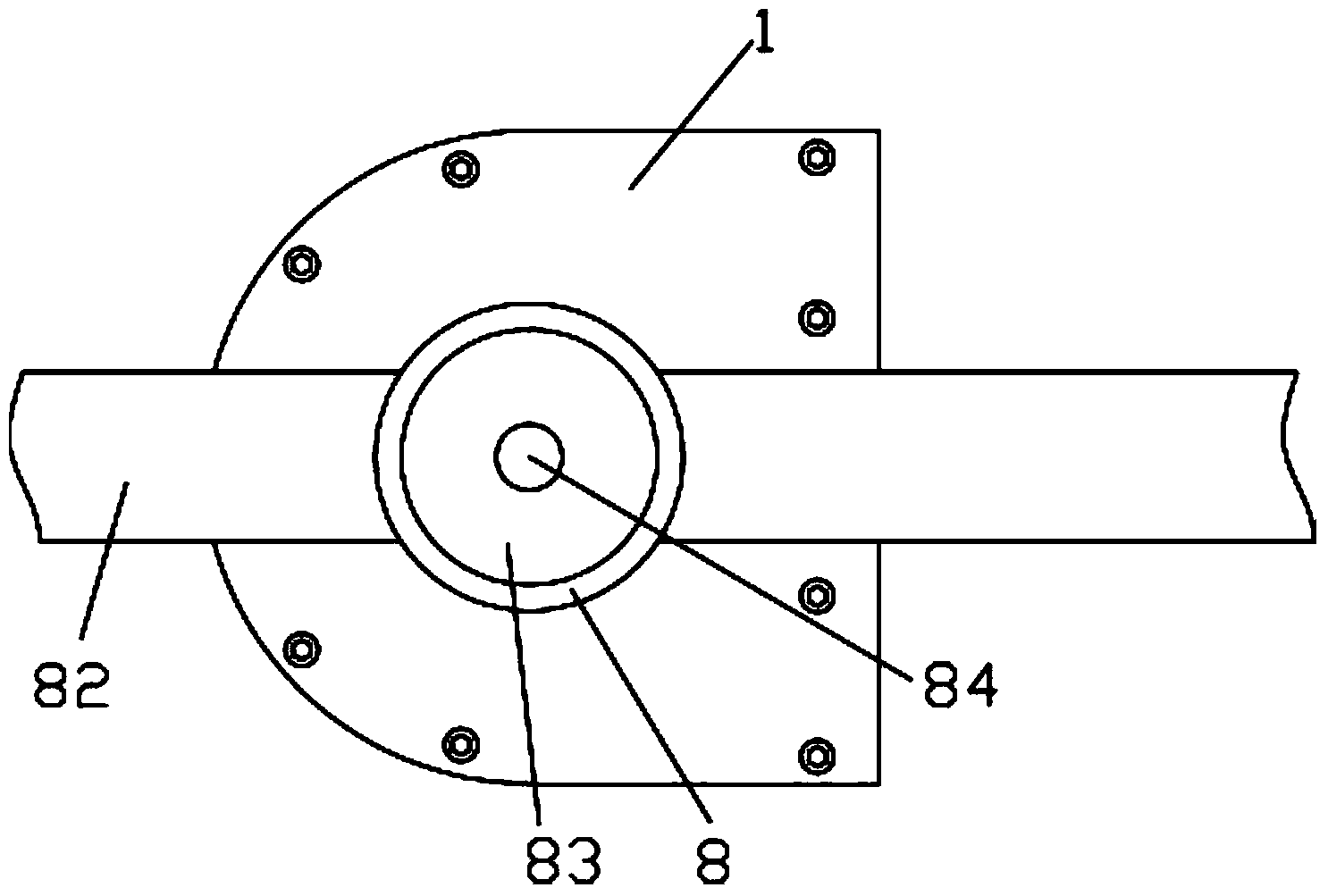

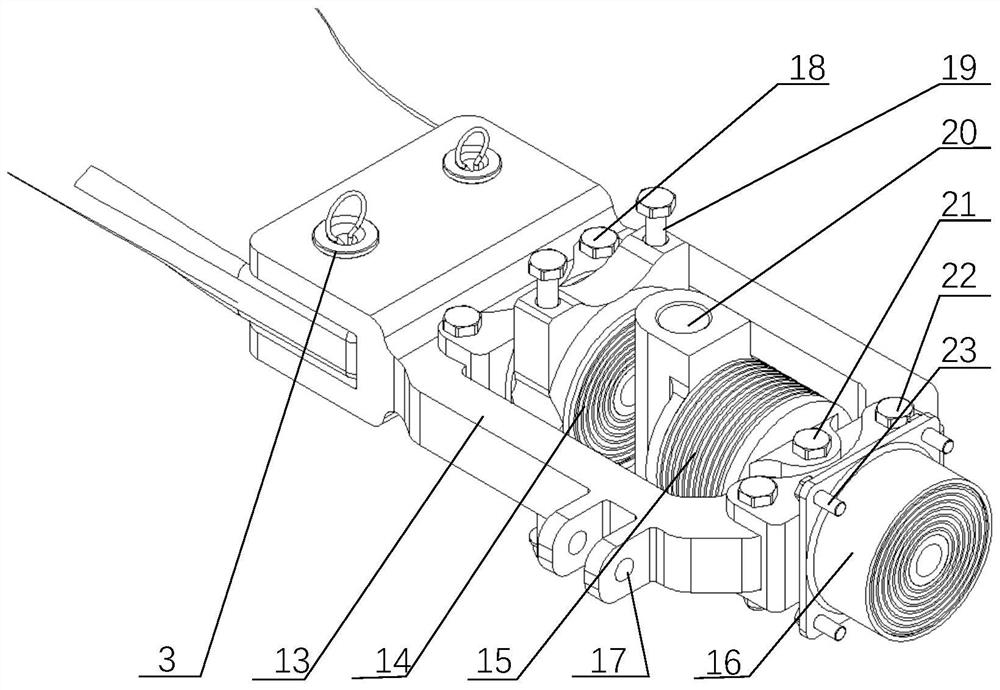

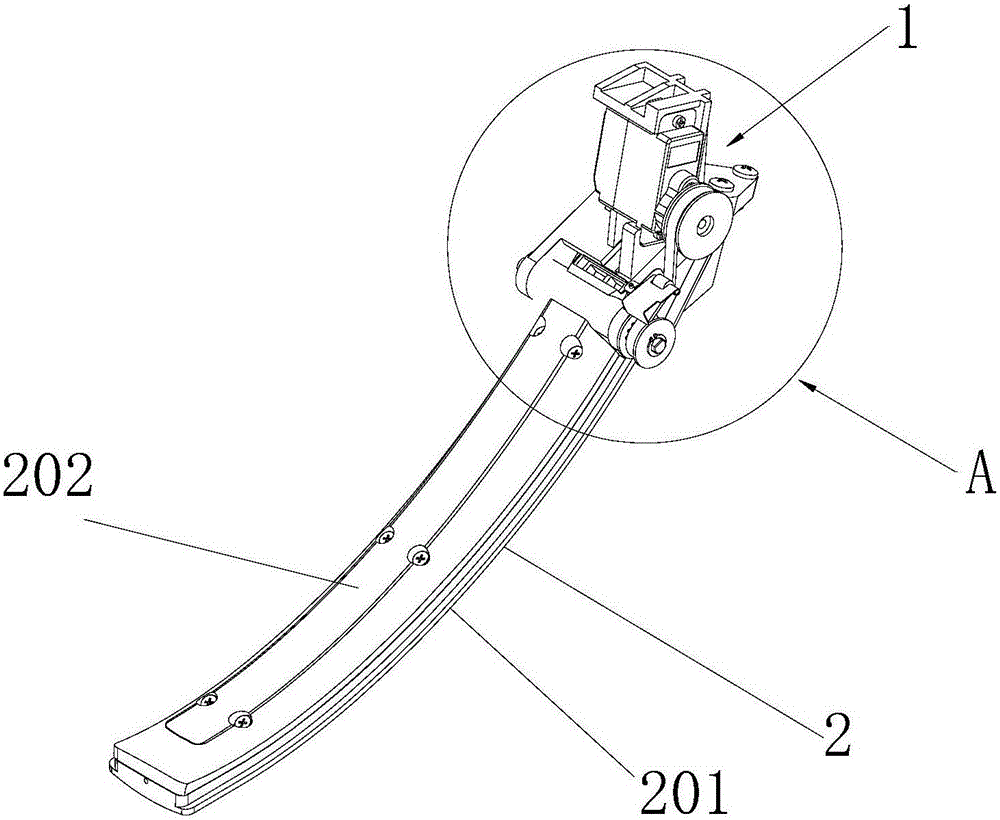

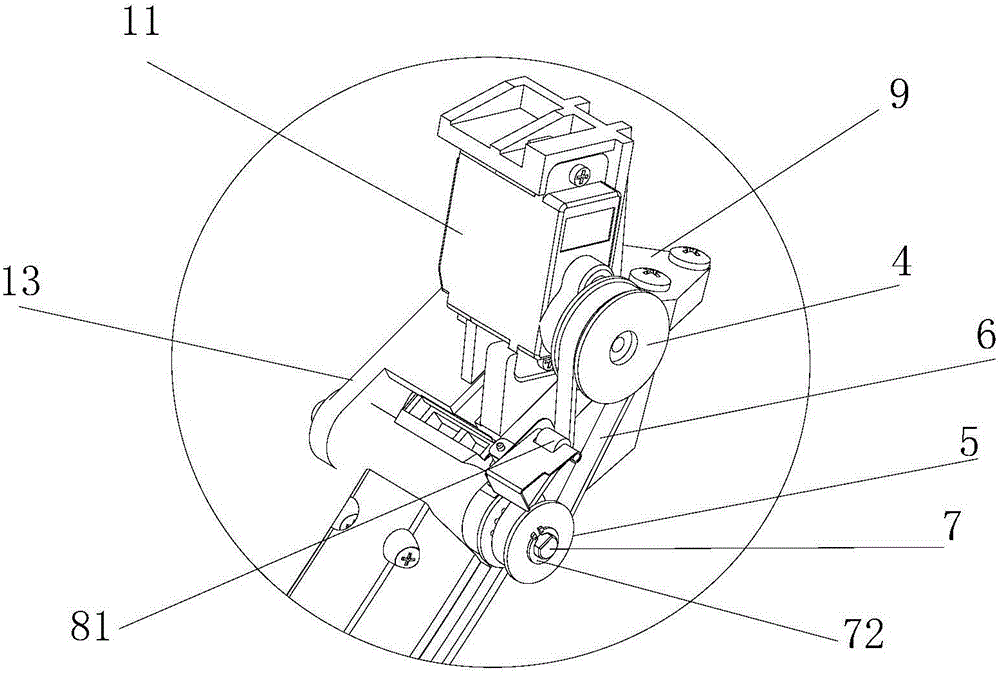

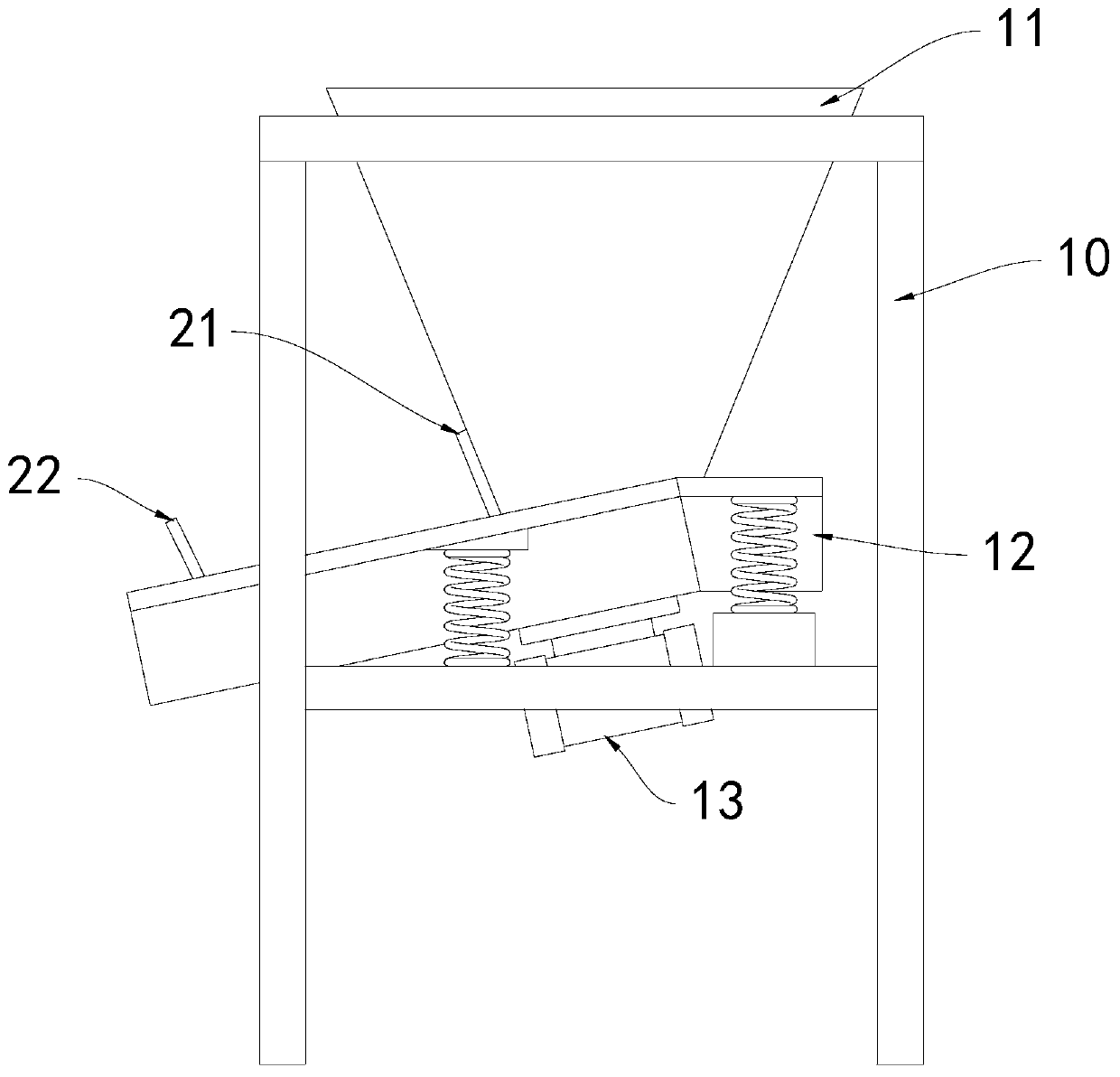

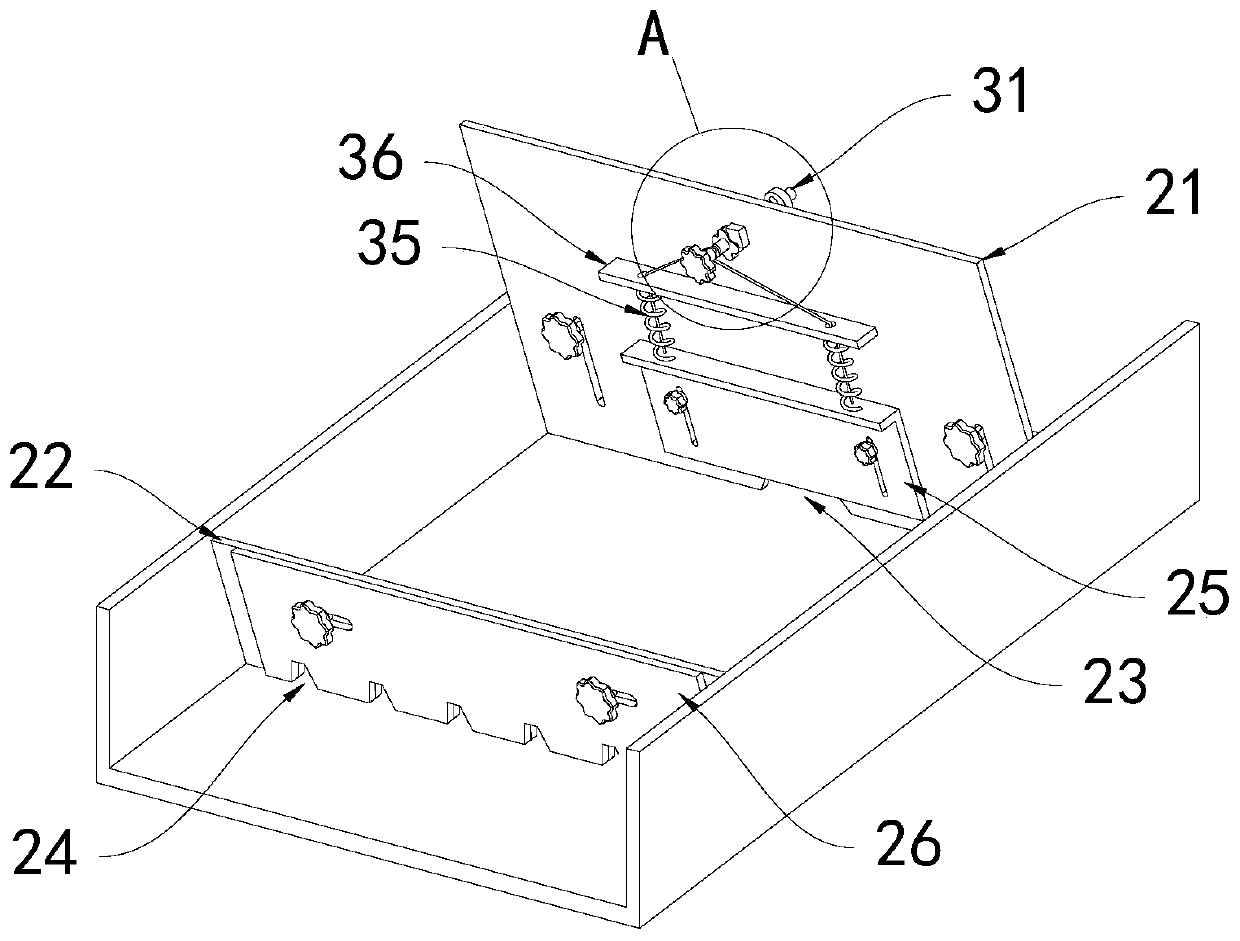

Foot-stand mechanism of unmanned aerial vehicle

The invention discloses a foot-stand mechanism of an unmanned aerial vehicle. The foot-stand mechanism comprises a support, a foot stand and a transmission mechanism, wherein the support is fixed to a main body of the unmanned aerial vehicle, the foot stand is rotatably connected with the support, and the transmission mechanism is arranged between the support and the foot stand. The transmission mechanism comprises a motor fixed to the support, a driving wheel fixedly connected with a motor shaft and a driven wheel, wherein the driven wheel and a rotary shaft of the foot stand are coaxially arranged, and the driving wheel and the driven wheel are connected through a bendable power transmission mechanism arranged between the driving wheel and the driven wheel in a sleeving mode. According to the foot-stand mechanism of the unmanned aerial vehicle, the function that the foot stand of the unmanned aerial vehicle can be folded is achieved, the foot stand of the unmanned aerial vehicle can be folded when not being used, the occupied space of the unmanned aerial vehicle is reduced, and storing is convenient and the foot stand is not liable to be damaged.

Owner:POWERVISION ROBOT INC

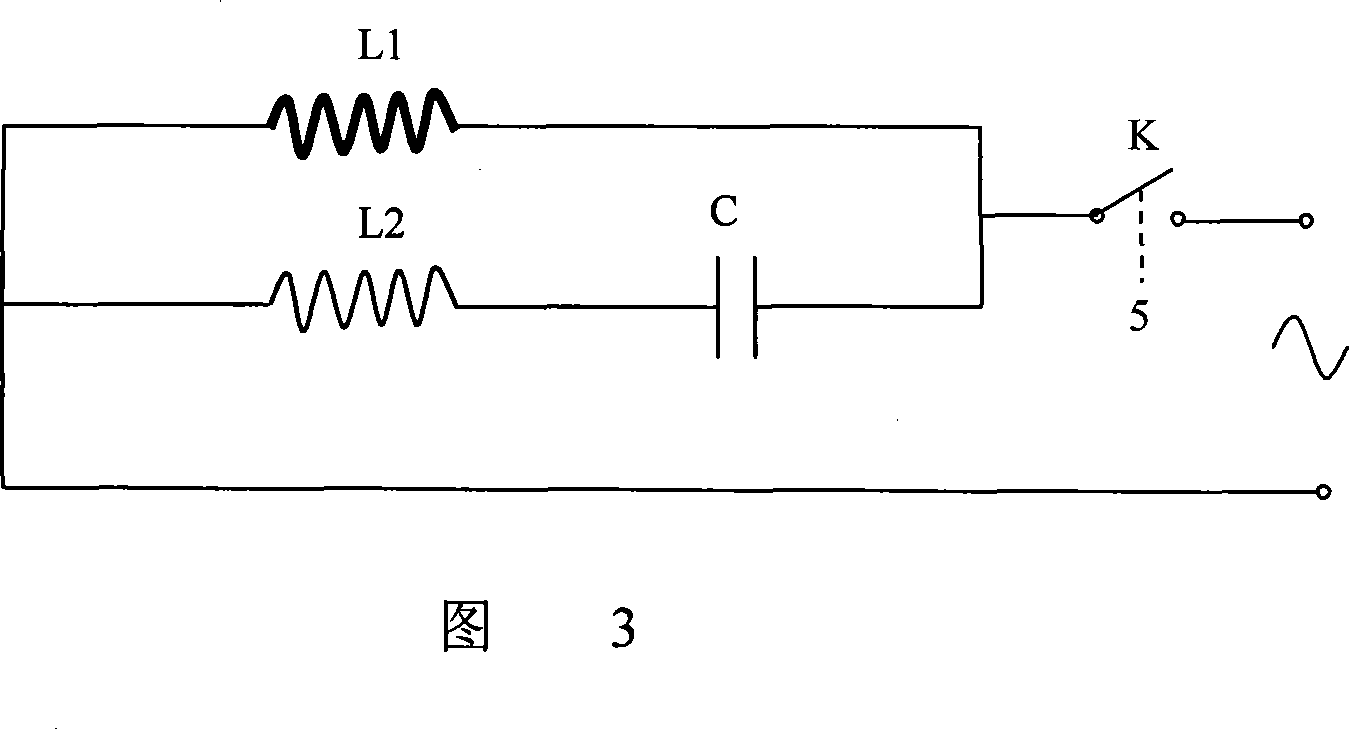

Uniform material scattering method and device for dried vegetable scraps

PendingCN109850530AEvenly distributedThe effect of uniform bulk materialLoading/unloadingConveyor partsComposite material

The invention discloses a uniform material scattering method and device for dried vegetable scraps. Through formation of material distributing holes distributed uniformly in a material flow path in the width direction of the path, materials are uniformly distributed in the width direction of the flow path after passing through the material distributing holes. According to the device, the materialscan be scattered uniformly, and the impurity removal efficiency is improved; and the labor intensity of operators is reduced. In addition, According to the device, the materials are not liable to block, and the structure is simple.

Owner:湖州鲜的食品有限公司

Piezoelectric actuator outputting dynamic micro angular displacement

ActiveCN103107733BImprove output accuracyNo clearancePiezoelectric/electrostriction/magnetostriction machinesPiezoelectric actuatorsControl theory

The invention relates to a piezoelectric actuator outputting dynamic micro angular displacement which comprises an output rod, a first spring slice and a second spring slice, a first T-shaped flexible restraint end connected with the first spring slice and a second T-shaped flexible restraint end connected with the second spring slice. The first spring slice and the second spring slice are respectively connected with upper and lower ends of two sides of the output rod. The first T-shaped flexible restraint end is connected in an external fixed frame through a first flexible hinge and a second flexible hinge on two sides of the first T-shaped flexible restraint end. The second T-shaped flexible restraint end is connected in an external fixed frame through a third flexible hinge and a fourth flexible hinge on two sides of the second T-shaped flexible restraint end. A first piezoelectric stack and a second piezoelectric stack are fixed on the first T-shaped flexible restraint end and the outer fixed frame. A third piezoelectric stack and a fourth piezoelectric stack are fixed on the second T-shaped flexible restraint end and the outer fixed frame. After forward voltage is exerted, length of the four piezoelectric stacks is prolonged and the two T-shaped flexible restraint ends are pushed to move to two sides so as to pull the two spring slices to two sides and consequentially, the output rod rotates around the symmetric center and micro angular displacement is output. The piezoelectric actuator is compact in structure, little in size and light in weight.

Owner:XI AN JIAOTONG UNIV

A deep slot single-phase capacitance operation linear motor

The invention discloses a deep-slot type single-phase capacitor running linear motor. It includes a primary and a composite secondary, and the primary units are arranged along the conveying line in a spaced distribution manner. It is characterized by: 1) Each primary iron core is provided with 4 deep grooves, and the ratio of the groove height to the groove width is 6~ 12. The windings in the slot are placed in layers; 2) The primary main winding and the secondary winding are asymmetrical, the number of turns and wire diameter are not equal, the secondary winding is connected in series with a capacitor C, and the primary winding is connected in parallel with the secondary winding after the series capacitor. The control switch is connected to the power supply; 3) The secondary operates in one direction relative to the primary, and the secondary is a copper-iron composite structure. The linear motor directly drives the load to run, with simple structure, low starting current, low noise, high efficiency, no need for lubrication, and high reliability. Its one-way movement meets the requirements of logistics conveyor lines, and is suitable for various types of production and commercial logistics lines in linear motion occasions, especially in supermarkets, pharmaceutical and civil logistics lines.

Owner:ZHEJIANG UNIV

Detachable pipe wrench

A detachable pipe wrench comprises a wrench body. The wrench body comprises an upper shell and a lower shell. A gear cavity is formed inside the upper shell and the lower shell. The middle of the upper shell is concaved downwards to form a circular groove, a circular through hole is formed in an upper bottom plate of the circular groove, three long through grooves and an inserting hole are formed in a bottom plate of the lower shell, three notches are formed in the bottom of the side wall of the lower shell, the notches are communicated with the tail ends of the long through grooves, long-strip-shaped grooves are formed in the two side walls of clamping blocks, and the two side walls of the long through grooves are inserted into the long-strip-shaped grooves in a sleeved mode. A Teflon layer is fixed on the lower bottom face of the upper bottom plate, the gear cavity is internally provided with a main bevel gear and a drive bevel gear which are meshed with each other, and the main bevel gear is arranged between the Teflon layer and the clamping blocks. The detachable pipe wrench is simple in structure, a user can hold two wrench arms to carry out double-hand operation by hands, efficiency is improved, the three clamping blocks and a circular elastic block are used for carrying out further clamping, the clamping effect is improved, and a pipe is prevented from skidding when rotating.

Owner:SUZHOU QISHUO INFORMATION TECH CO LTD

Piezoelectric driven micro-positioning platform based on hourglass displacement amplifier mechanism

InactiveCN108199610ASolve the problem of small output displacementHigh positioning accuracyPiezoelectric/electrostriction/magnetostriction machinesElectricityEngineering

The invention provides a piezoelectric driven micro-positioning platform based on an hourglass displacement amplifier mechanism. The platform comprises an outer-layer support (3), the hourglass displacement amplifier mechanism, a piezoelectric ceramic actuator (2), symmetrical long arm hinges, a workbench (6) and an inner-layer substrate (7). The hourglass displacement amplifier mechanism comprises an x-direction hourglass displacement amplifier mechanism (1) and a Y-direction hourglass displacement amplifier mechanism (4). The symmetrical long arm hinges comprise x-direction symmetrical longarm hinges (5) and Y-direction symmetrical long arm hinges (8). The piezoelectric driven micro-positioning platform based on the hourglass displacement amplifier mechanism can realize large-stroke motion of the workbench. Certainly, implementation of any product or method of the invention does not necessarily require all the advantages described above to be achieved simultaneously.

Owner:SHENYANG POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com