A deep slot single-phase capacitance operation linear motor

A linear motor, deep groove technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of short running time, frequent starting, low efficiency, etc., and achieve the effect of simple structure, high reliability and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention will be specifically described below in conjunction with the embodiments and the accompanying drawings.

[0016] Refer to attached picture.

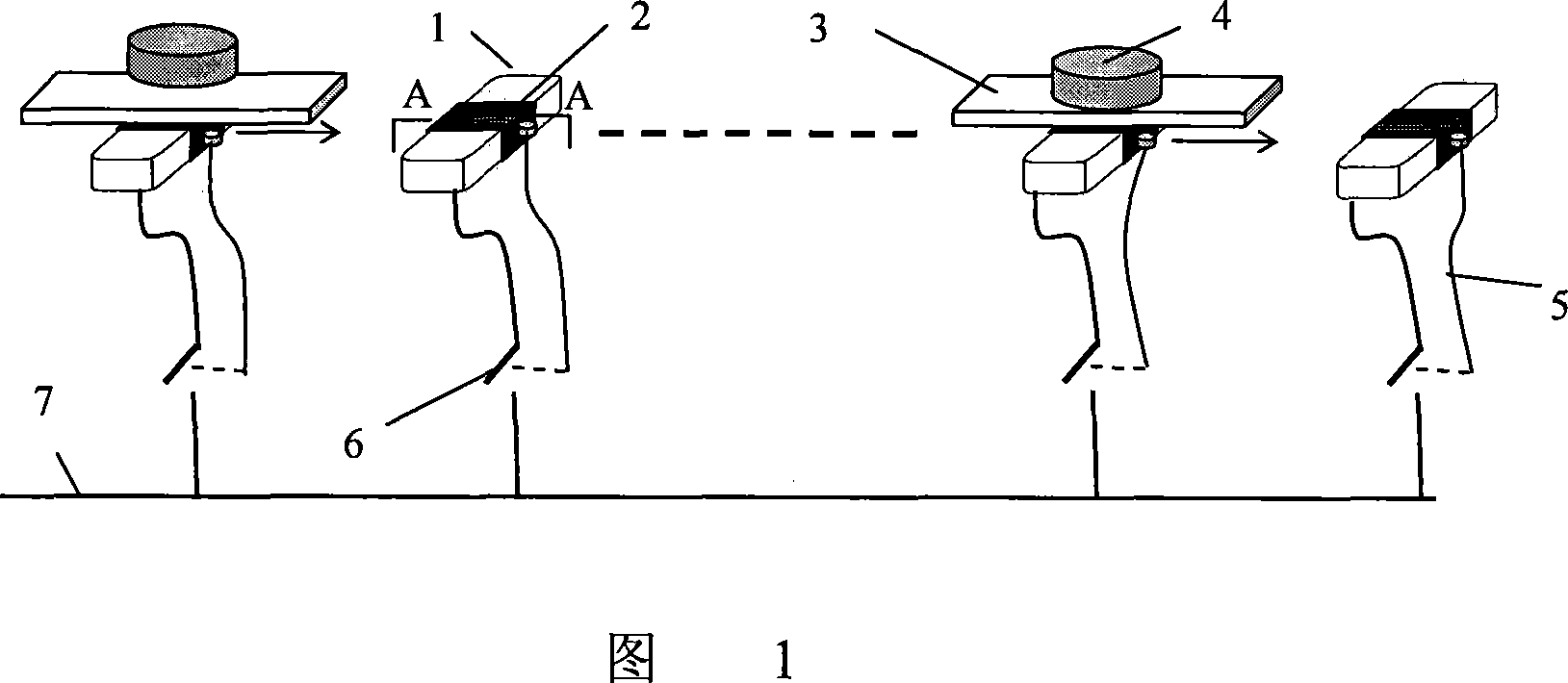

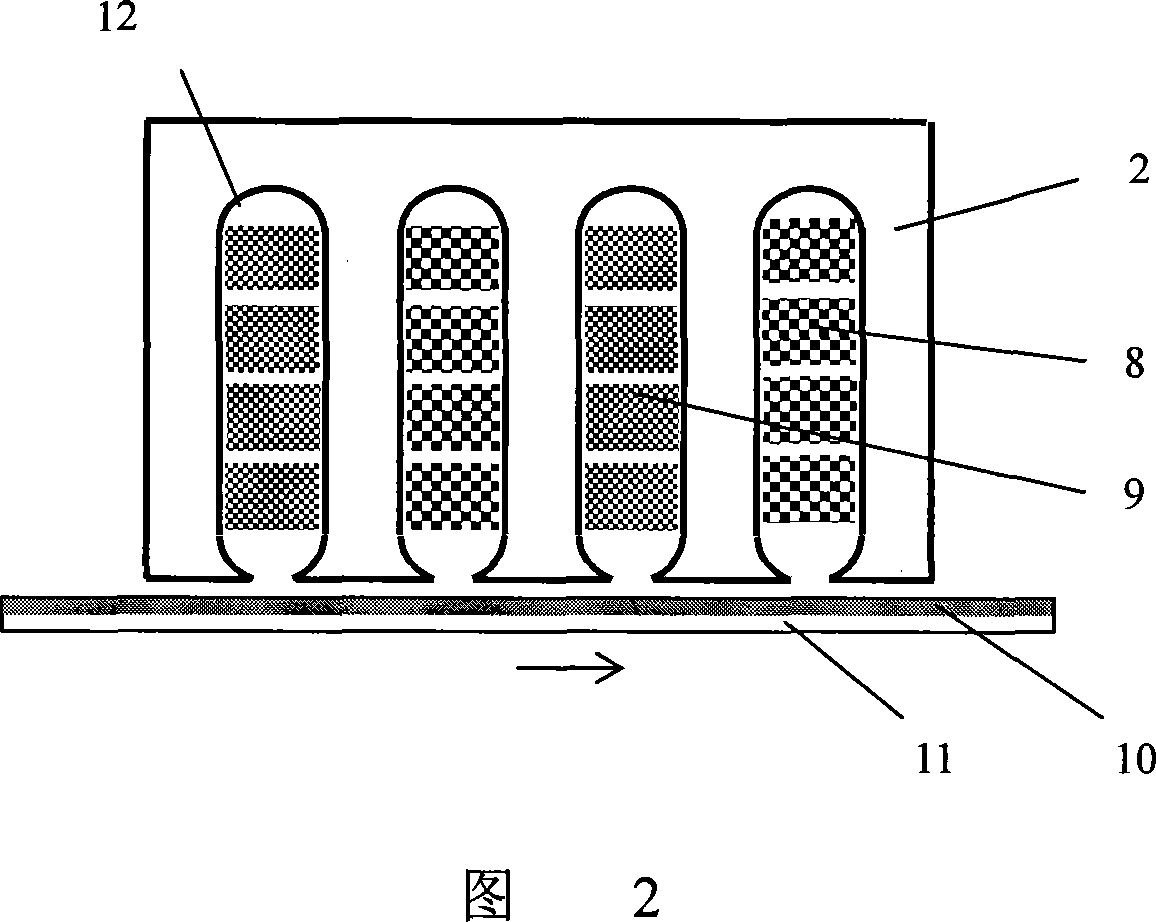

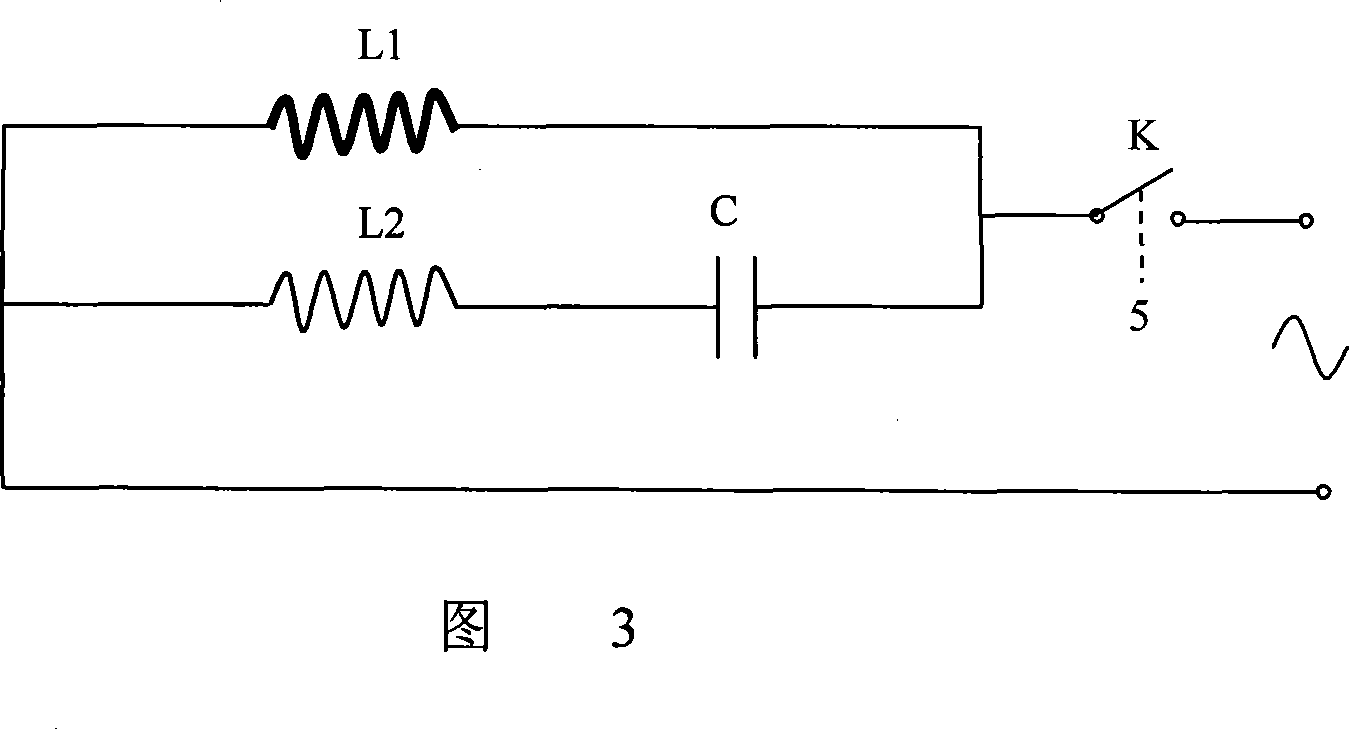

[0017] Figures 1 and 2 are examples of linear motors operated by deep groove single-phase capacitors of the present invention. It includes a primary 1 and a composite secondary 3, and its features are: 1) The primary units are distributed along the guide rail of the transmission line, and each primary core 2 is provided with 4 deep grooves 12, and the ratio of the groove height to the groove width is equal to 8.6, the winding in the slot is placed in layers, and the end of the winding is packaged with BMC; 2) the winding in the slot is placed in layers, the primary main winding 8 and the secondary winding 9 are asymmetrical, the number of turns and the wire diameter are different, and the wire diameter of the main winding is thicker , the number of turns is small, and several layere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com