Ultra precision positioning workbench with nanometer resolution

A workbench and resolution technology, used in manufacturing tools, large fixed members, metal processing equipment, etc., can solve the problems of motion accuracy and positioning accuracy that are difficult to reach sub-micron or even nanometer level, and achieve light weight and displacement resolution. High efficiency and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

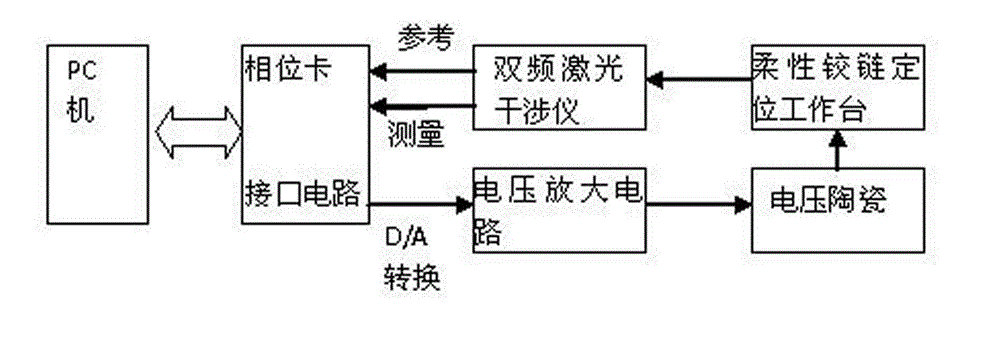

[0011] As shown in the figure, the main body of the present invention is composed of a flexible hinge worktable and a piezoelectric ceramic micro-displacer. It is detected by a dual-frequency laser interferometer SJD5, and a closed-loop control system is composed of a computer and a phase meter; a digital signal is given by the computer, D / A is converted and amplified to generate a variable voltage of 0~1000V with a step length of 1V, which drives the piezoelectric ceramic to expand and contract, and then the piezoelectric ceramic drives the flexible hinge worktable to make a micro displacement.

[0012] As a preferred solution, the control part adopts PC control.

[0013] Micro-actuator-the choice of piezoelectric ceramics.

[0014] The piezoelectric ceramic PZT1 developed by the Institute of Acoustics of the Chinese Academy of Sciences and the piezoelectric ceramic PZT2 manufactured by the German PI company in the early 1990s are used as the driving parts. The range of these t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com