Molded-product removing device

A technology for taking out devices and molded products, which is applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc. It can solve the problems of high overall height and the taking-out device of molded products cannot be installed on the molding machine, and achieve the effect of suppressing height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

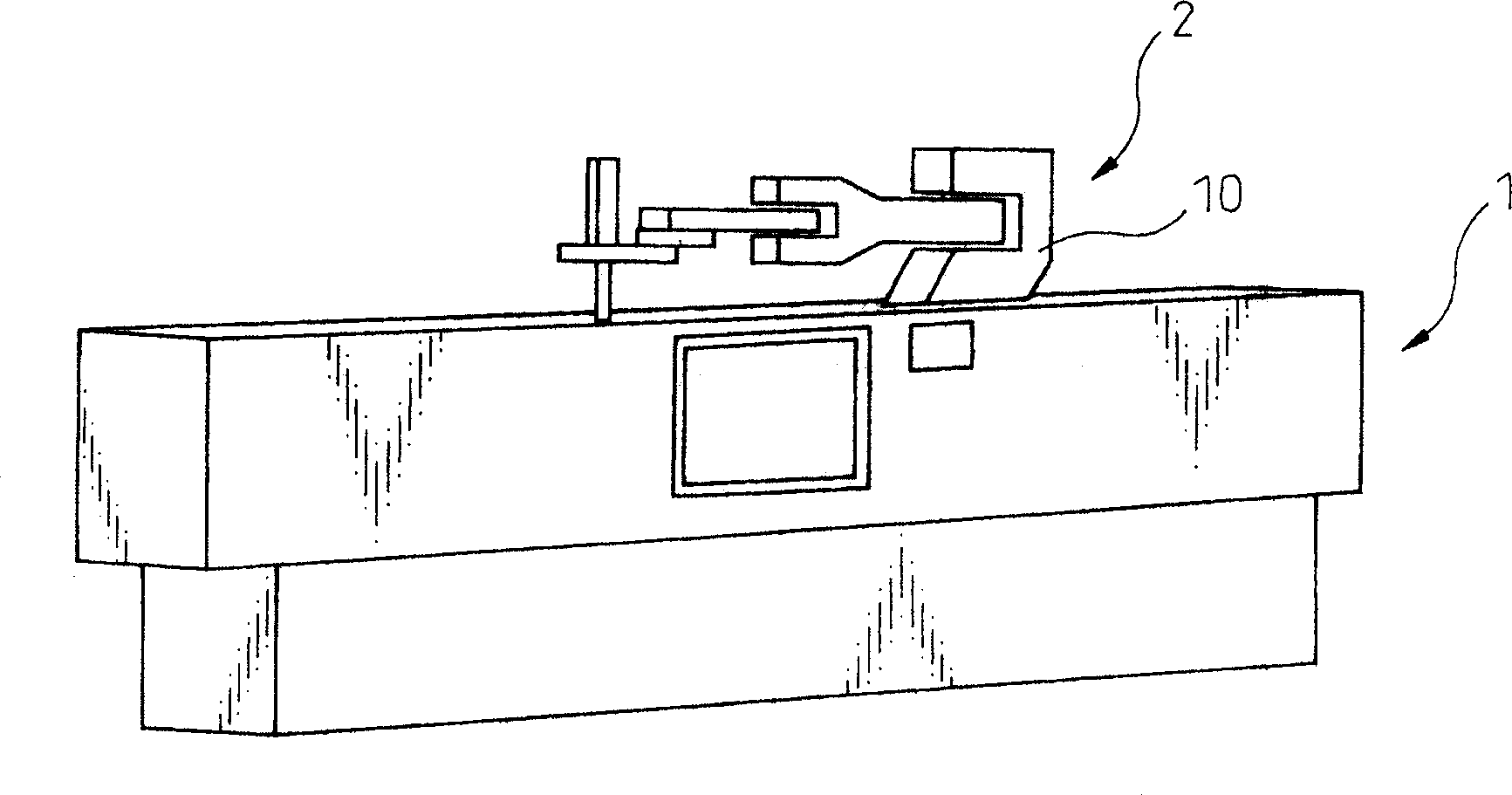

[0026] figure 1 It is a schematic perspective view of the molding machine 1 and the molded product taking-out device 2 according to one embodiment of the present invention mounted on the molding machine 1. The molded product take-out device 2 is installed on the upper part of the molding machine 1, for example, on a fixed plate of the molding machine 1 or the like.

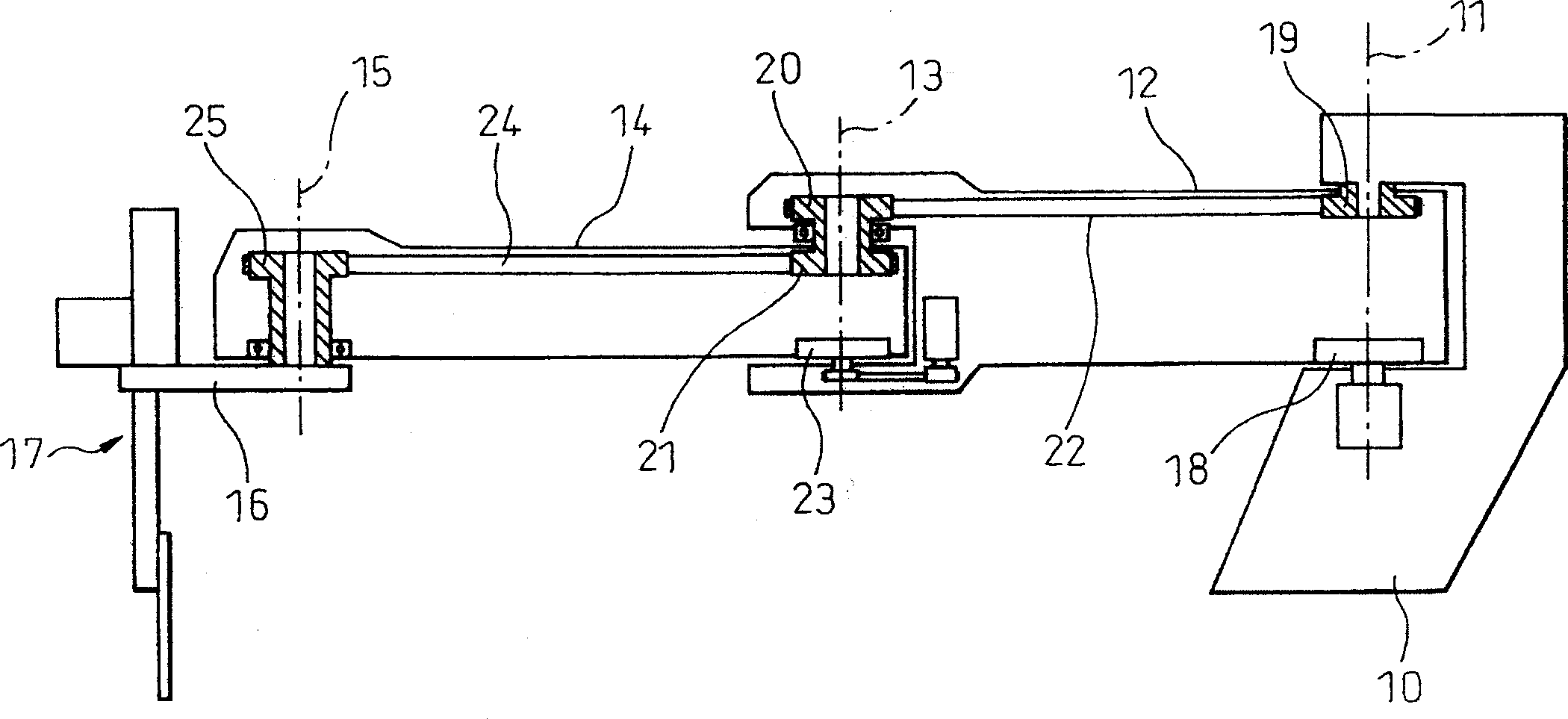

[0027] figure 2 This is a schematic diagram of the structure of the molded product extraction device 2. The molding machine 1 is provided with a base 10 for installing the molded product take-out device 2 on the molding machine 1. The first rotating arm 12 of the hollow structure is supported by a cantilever at one end thereof so as to be rotatable about a first axis 11 extending in the vertical direction. On the base 10. The second rotating arm 14 of the hollow structure is rotatably supported on the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com