Force Control Module Based on Variable Stiffness Flexible Mechanism

A flexible mechanism and control module technology, which is applied to the parts of grinding machine tools, grinding automatic control devices, manufacturing tools, etc., can solve the problems of workpiece or robot system damage, slow stiffness change speed, and bulky mechanism, etc. The effect of mass production, small dead stroke, and easy miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

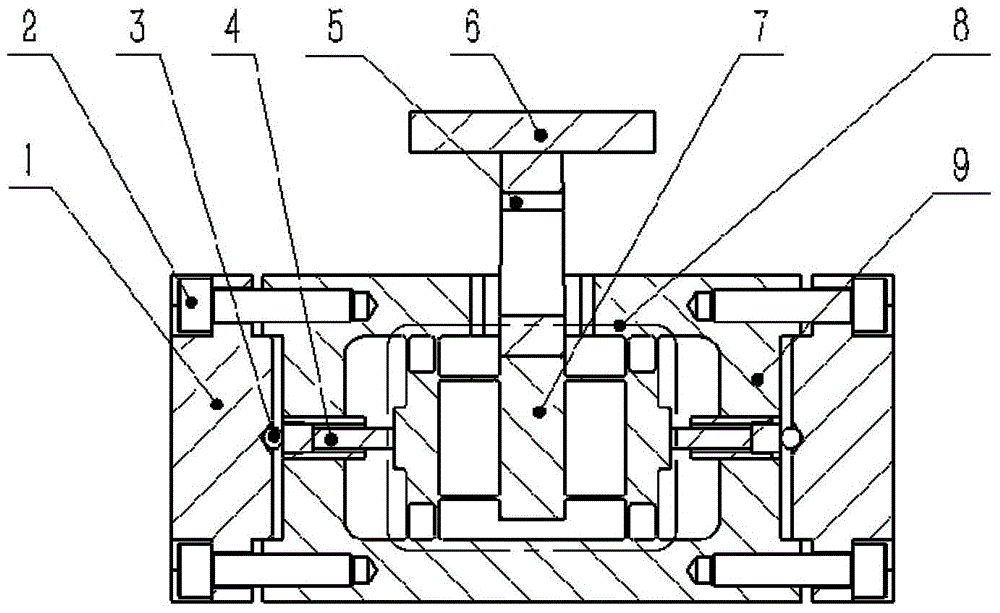

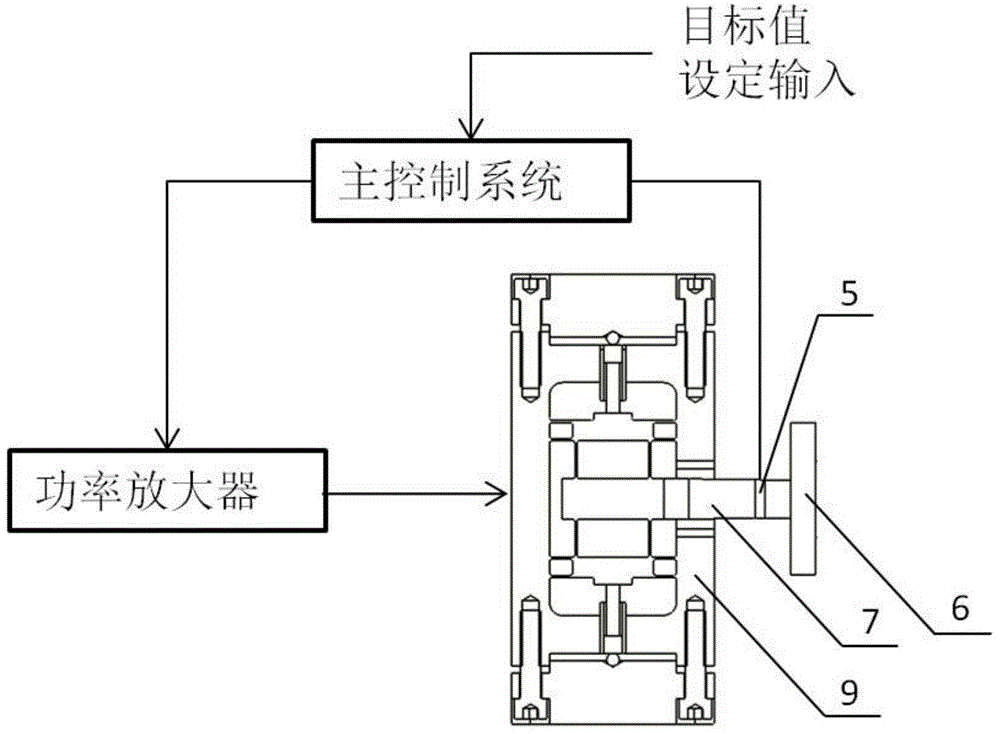

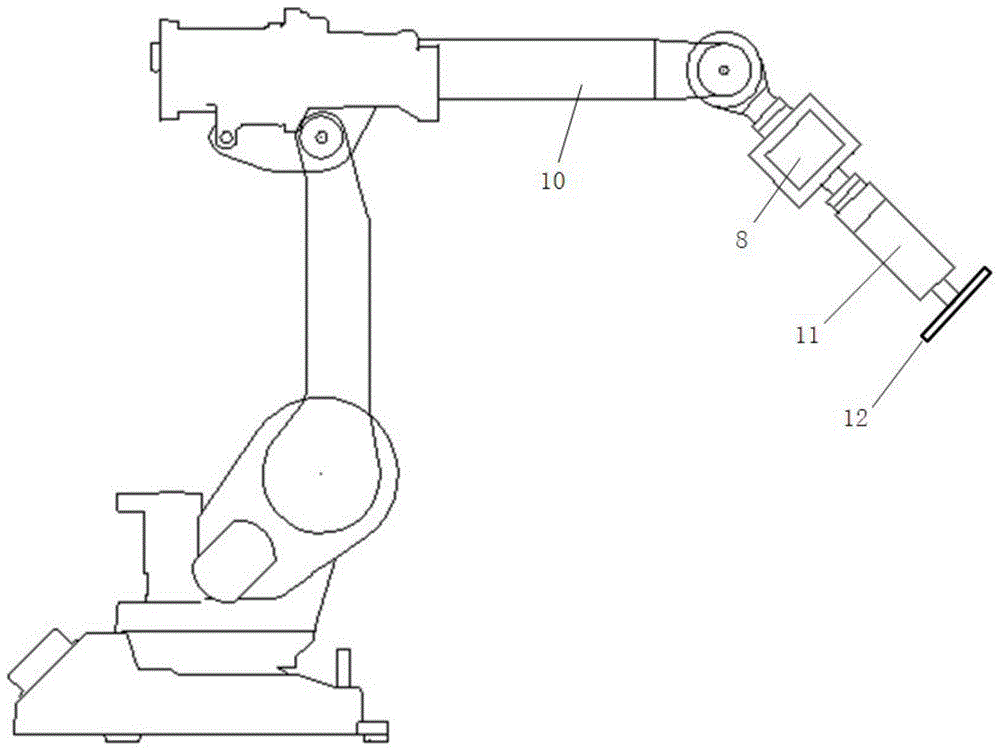

[0024] Example: such as figure 1 As shown, the present invention includes a housing 9, a cover plate 1 placed at both ends of the housing 9, a flexible mechanism 8, a piezoelectric driver 4, a pre-tightened steel ball 3 and a sensor 5, and the flexible mechanism 8 is placed in the housing 9 Between the two cover plates 1, piezoelectric actuators 4 are respectively arranged between the two ends of the flexible mechanism 8 and the cover plate 1, a pre-tightening steel ball 3 is arranged between the cover plate 1 and the piezoelectric actuator 4, and the sensor 5 is placed in a flexible The output terminal of mechanism 8.

[0025] The flexible mechanism 8 includes at least two rows and two rows of criss-cross leaf-shaped shrapnel and an output shaft 7, on which a sensor 5 is arranged; the output shaft 7 is connected between the criss-crossed leaf-shaped shrapnel , the ends of the two transverse leaf-shaped shrapnel are respectively in contact with the piezoelectric driver 4 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com