Magnetic Suspension Bearing Isolation Rotor Structure

A magnetic levitation bearing and rotor structure technology, applied to bearings, shafts and bearings, mechanical equipment, etc., can solve problems such as internal mechanical corrosion, deflagration hazard, and affecting heat dissipation of internal parts, and achieve long life, low cost, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

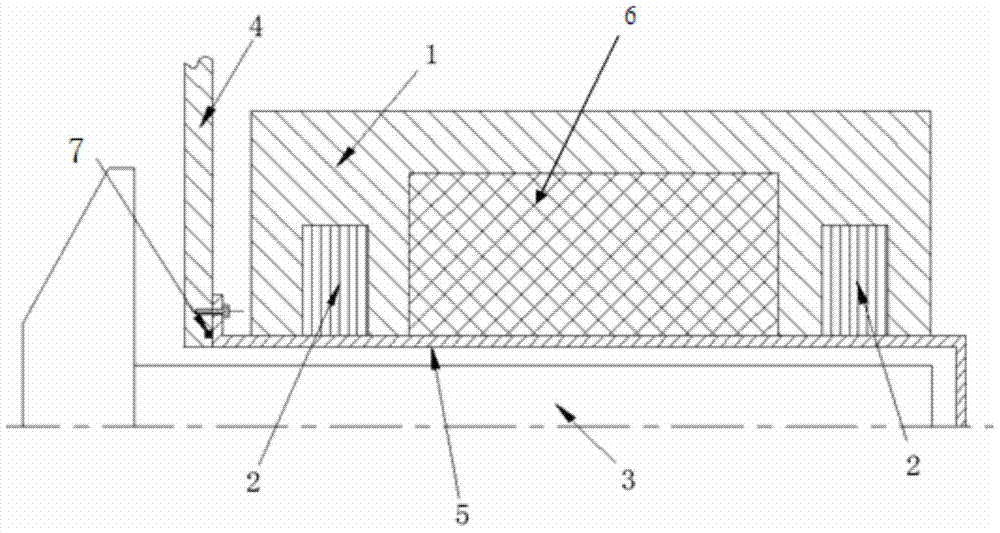

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

[0018] Such as figure 1 As shown, the magnetic suspension bearing isolation rotor structure of the present invention includes a base 1, a magnetic suspension bearing 2, a rotor 3 and a stator 6, the magnetic suspension bearing 2 and the stator 6 are all supported on the base 1, and the rotor 3 is passed through the magnetic suspension bearing 2 and the stator within 6. A sheath 5 is provided between the rotor 3, the magnetic suspension bearing 2 and the stator 6. The sheath 5 is a barrel-shaped structure with one end open and the other end closed. The container 4 is airtightly connected, and the inner cavity of the sheath 5 communicates with the inner cavity of the fluid container 4 , and the left end of the rotor 3 extends into the inner cavity of the fluid container 4 .

[0019] In the present invention, a static seal is adopted between the sheath 5 and the fluid c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com