Optical fiber preformrod collet

An optical fiber preform and preform technology, applied in the field of optical fiber manufacturing, can solve the problems of high processing cost and operation difficulty, preform falling off, damage to drawing tower, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

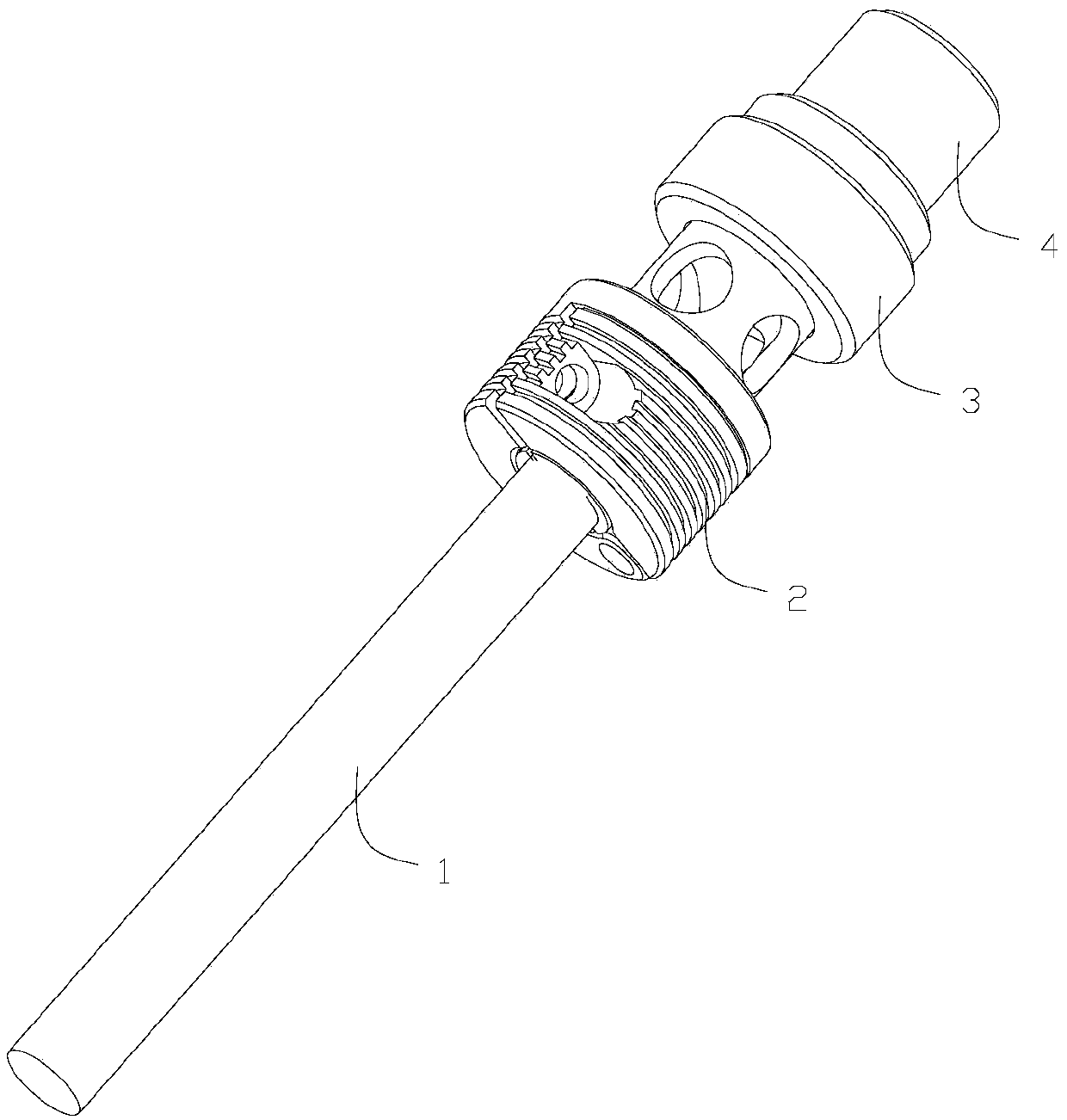

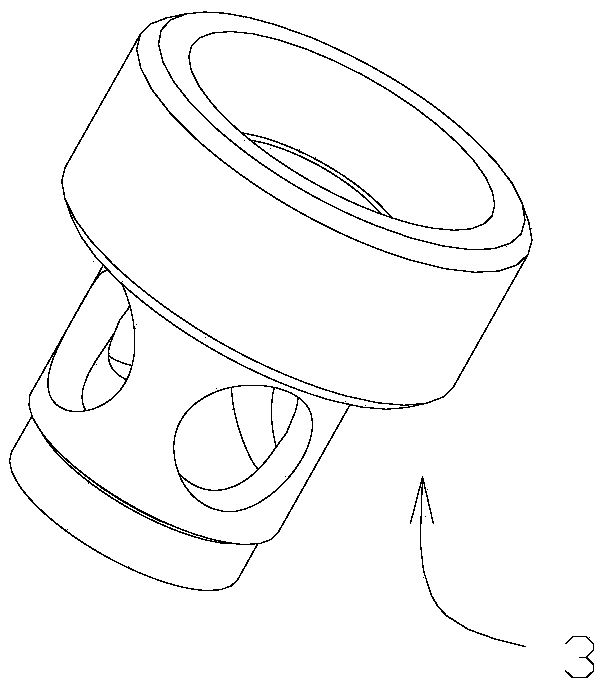

[0021] refer to figure 1 , an optical fiber preform chuck, including a preform holder 2 , a heat sink 3 and a connector 4 . The upper end of the fixing seat 2 is connected with the lower end of the cooling element 3 through threads, and the upper end of the cooling element 3 is connected with the lower end of the connecting element 4 through threads. The upper end of the connector 4 can be quickly clamped on the three-jaw chuck, and the optical fiber preform 1 is clamped in the fixing seat 2 .

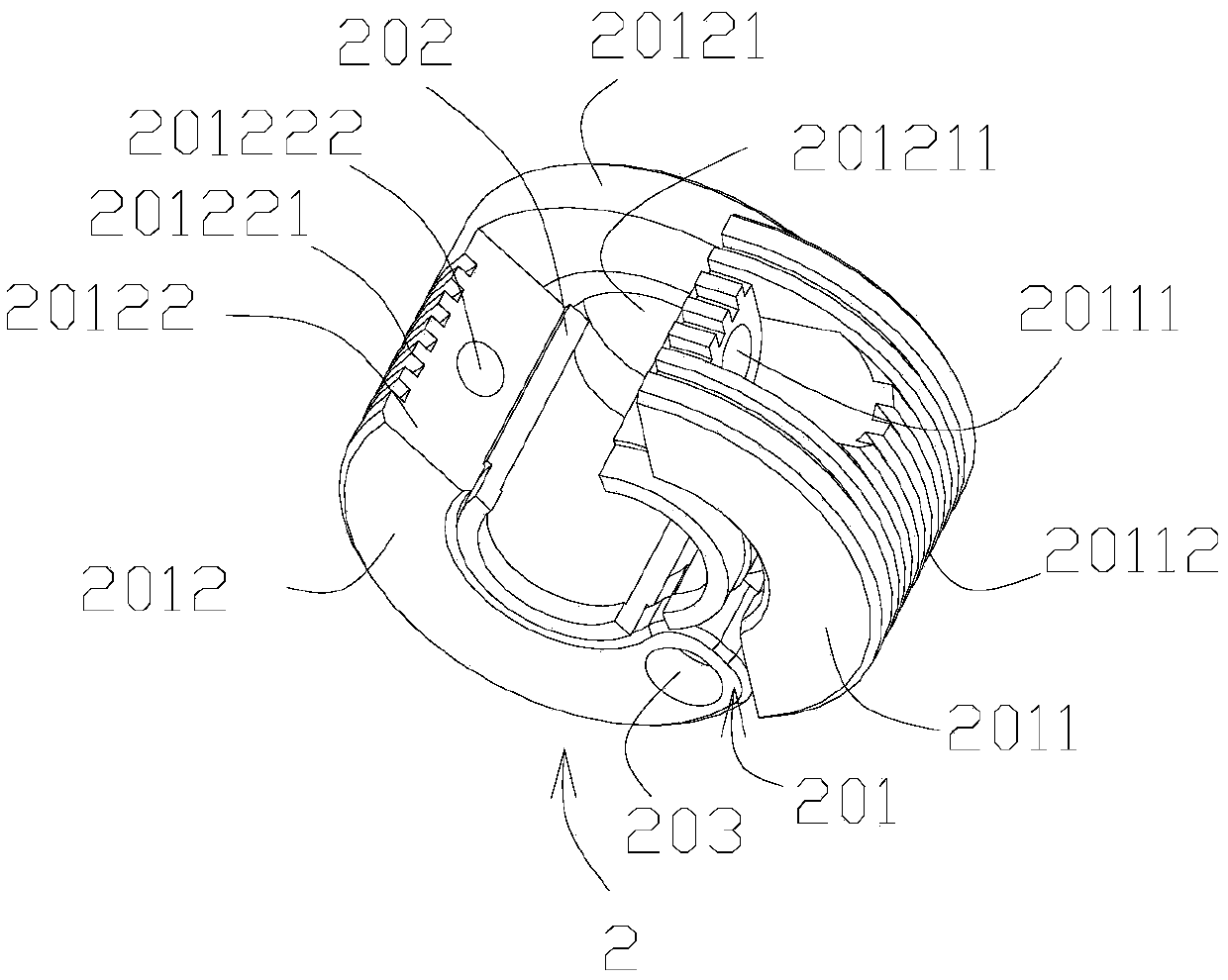

[0022] refer to figure 2 , The preform holder 2 includes a clamping member 201 and an opening and closing bushing 202 .

[0023] The clamping part 201 is in the shape of a hollow cylinder and consists of a movable clamping valve 2011 and a fixed clamping valve 2012 . The upper end of the fixed clamping valve 2012 is provided with a heat sink connecting part 20121, which is flat and cylindrical, and its central part is provided with a threaded through hole in the axial direction; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com