Fluid-actuated diaphragm drive

A driver and diaphragm technology, applied in the direction of fluid pressure actuation devices, etc., can solve problems such as difficult to clean and easy to be polluted, and achieve an effect that is conducive to effective cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

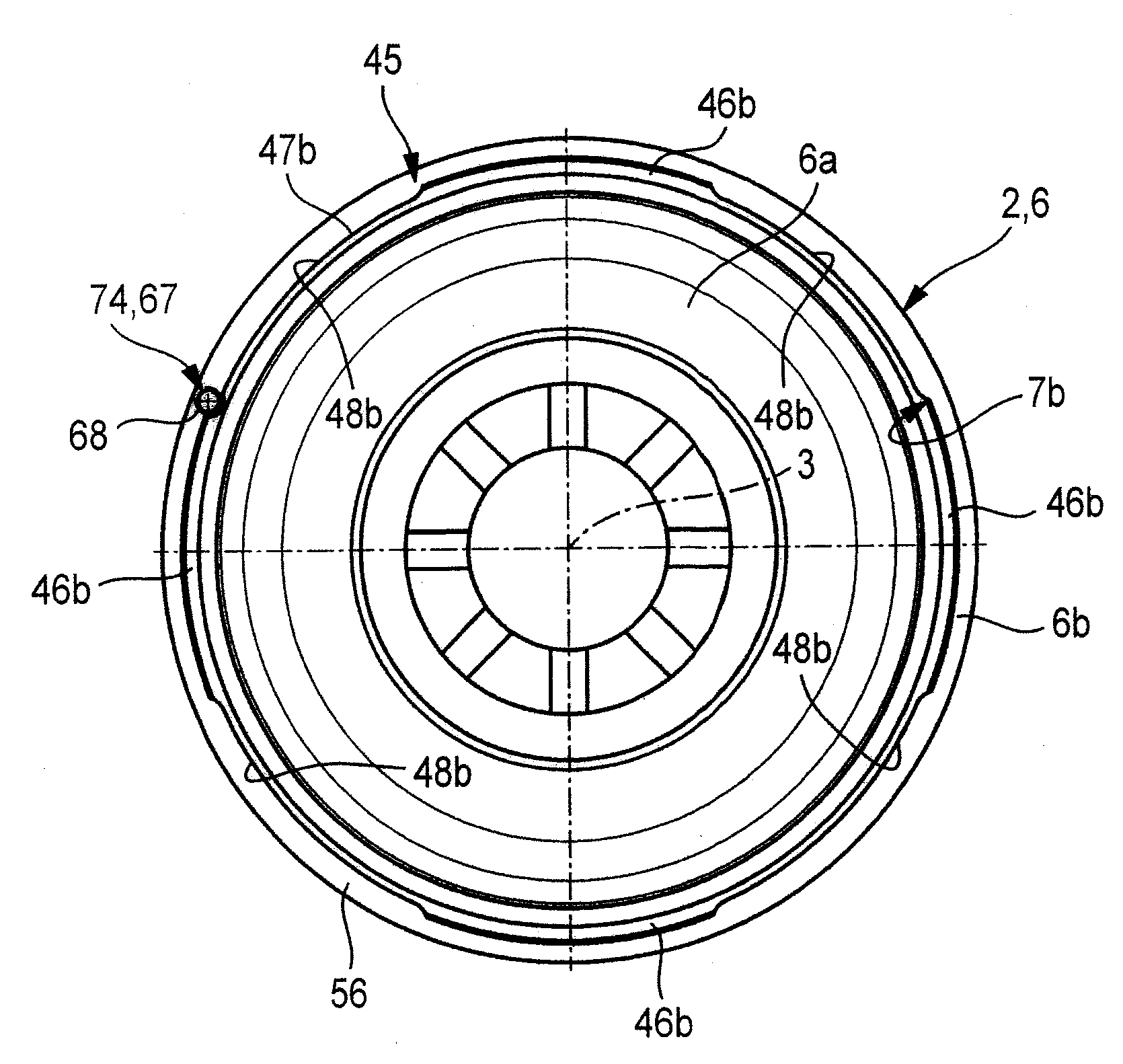

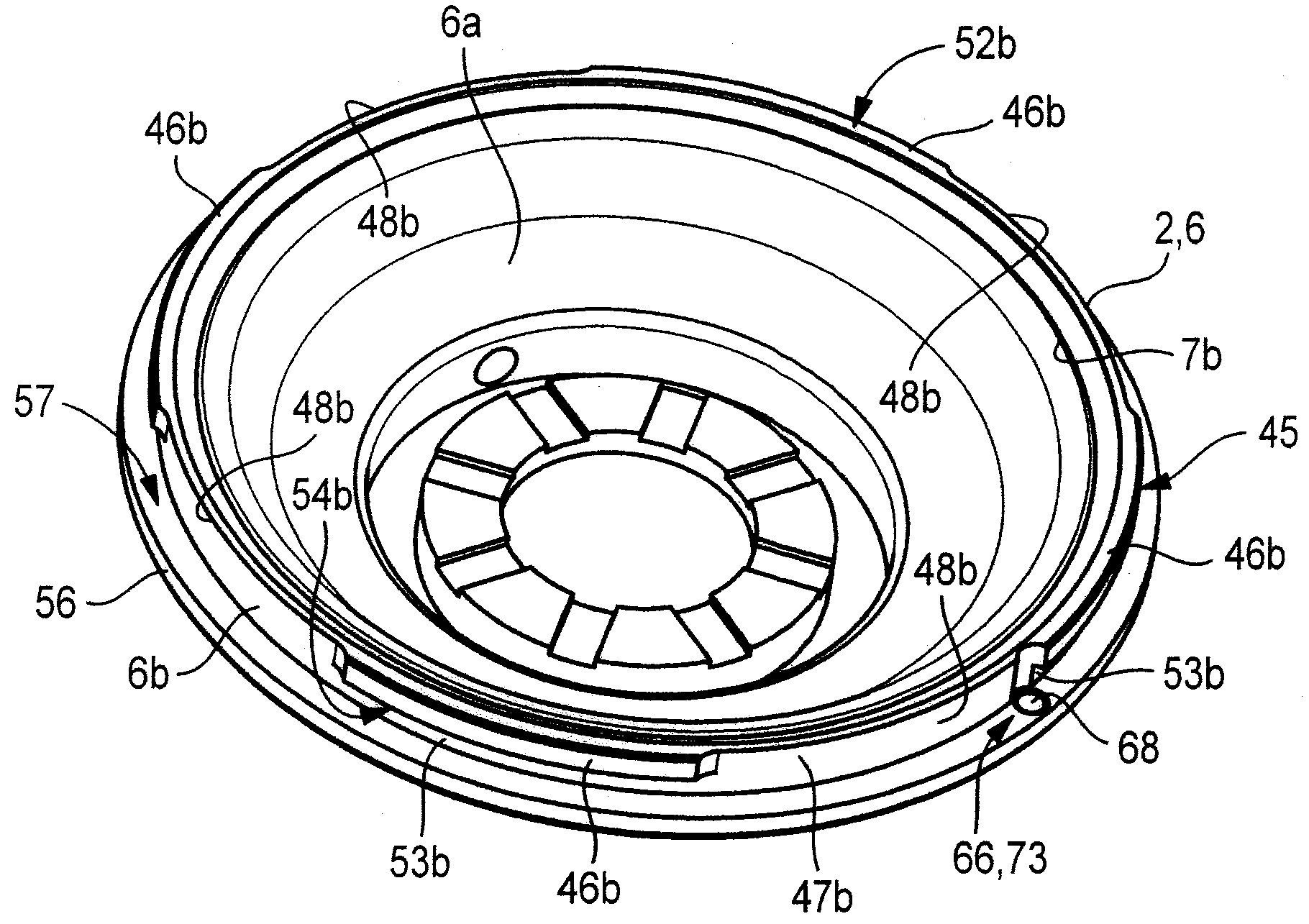

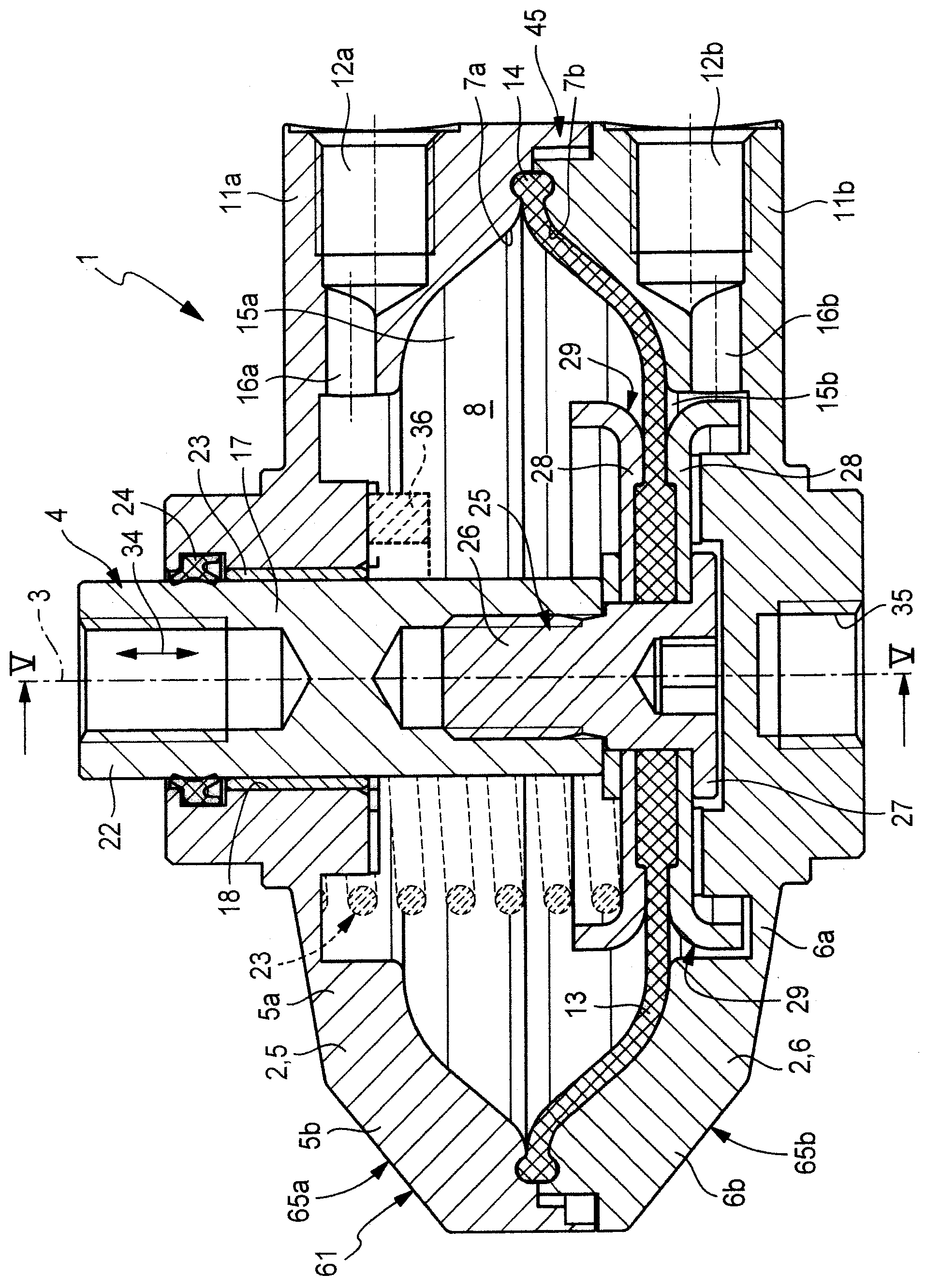

[0062] The diaphragm drive, which is denoted as a whole by the reference number 1 , is designed for controlled actuation by means of fluid forces, wherein the fluid forces are provided by a fluid drive medium which can be fed in and out as required. The drive medium is especially compressed air. However, the diaphragm drive can also be operated with other gaseous drive media and also with liquid drive media.

[0063] The diaphragm drive 1 has a housing 2 with a longitudinal axis 3 . It also has a drive unit 4 that is linearly movable relative to the housing 2 in the axial direction of the longitudinal axis 3 . The relative movement of the drive unit 4 with respect to the housing 2 is brought about by a controlled fluid loading on the drive medium.

[0064] The housing 2 has two bell-shaped housing parts 5 , 6 , which are subsequently also referred to as first and second housing parts 5 , 6 for better differentiation. Each housing part 5 , 6 has an in particular approximatel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com