Knitting machine

A knitting machine and knitting needle technology, applied in the field of knitting machines, can solve problems such as increasing production costs, and achieve the effects of reducing production costs, reducing manufacturing precision, and fast and easy assembly and replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

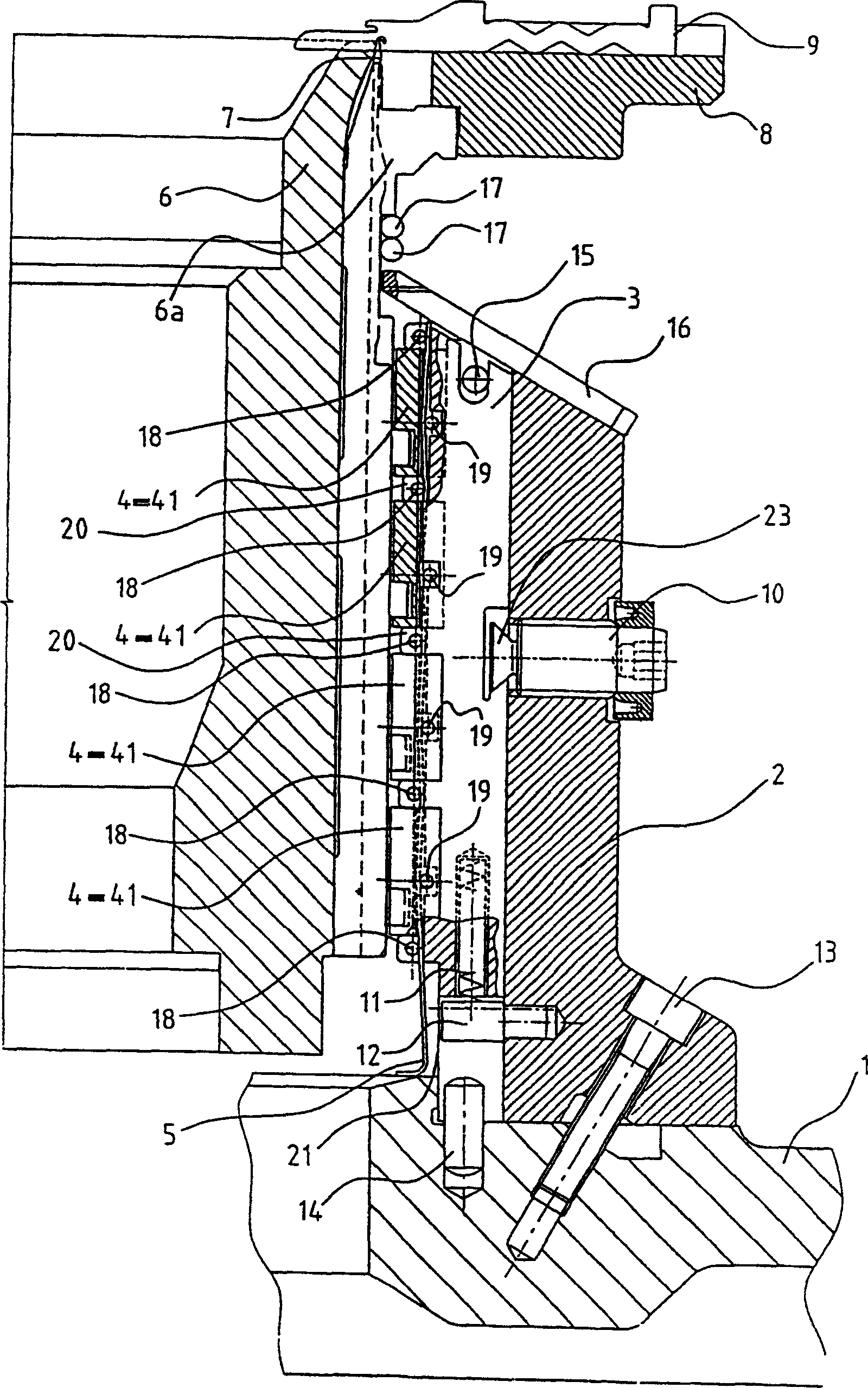

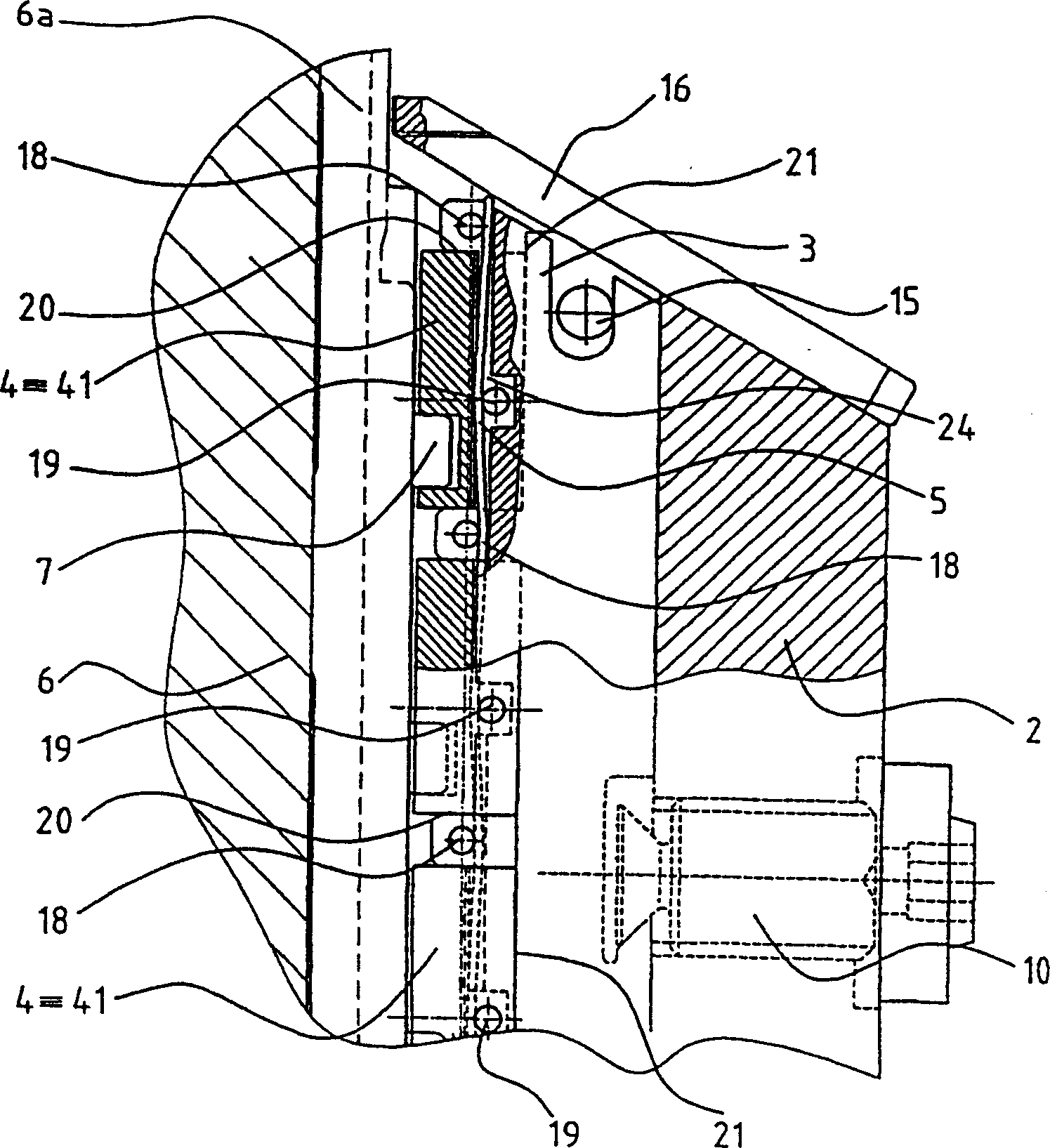

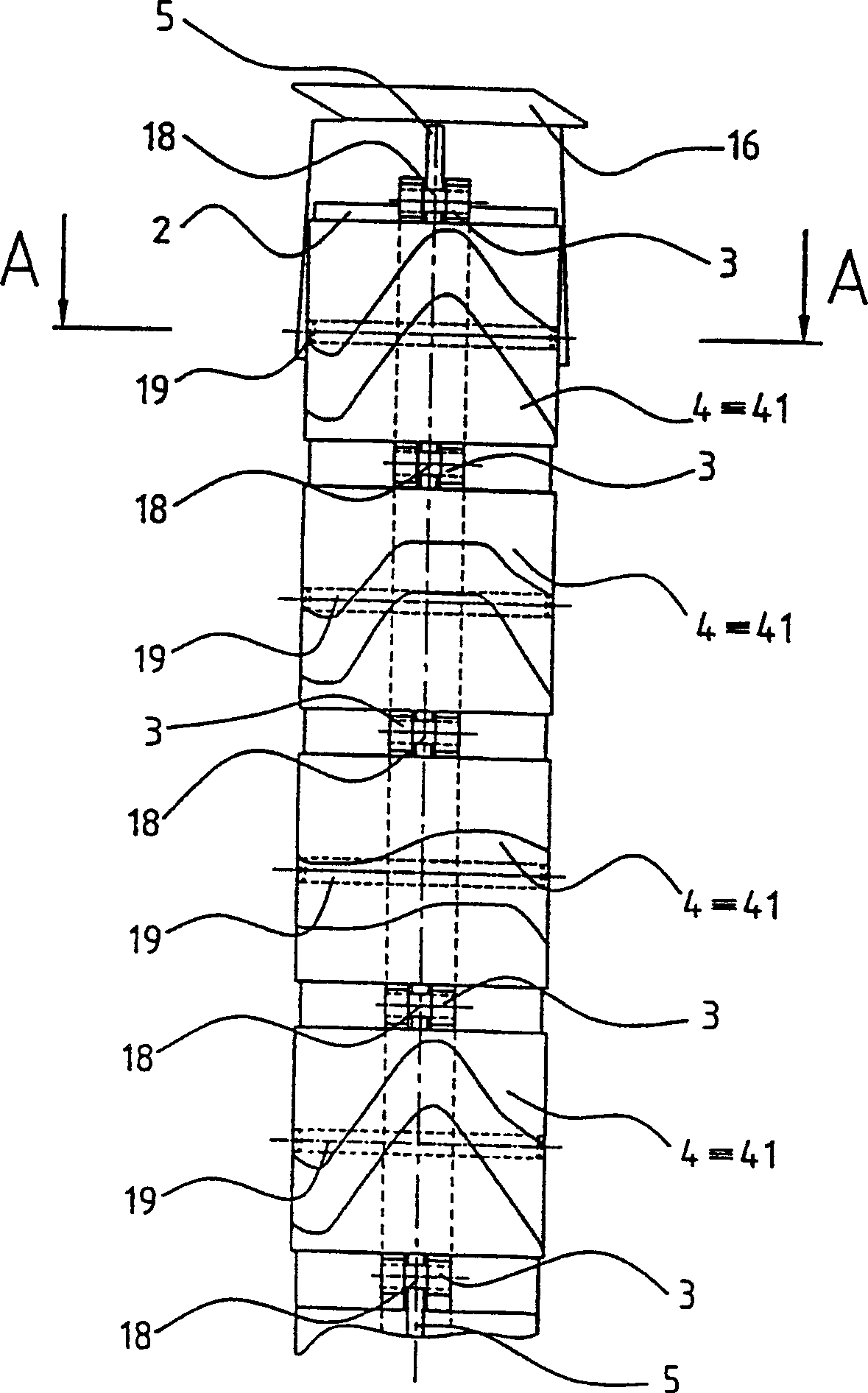

[0035] The present invention will be illustrated with a circular knitting machine with a single base plate, the parts that are more important to the present invention are shown in section in figure 1 , and in the area of a circular cylindrical base plate 6 is shown as a knitting needle cam seat system, and shows the details necessary to illustrate the principles of the invention. Details about the fixing and driving of the base plate 6 and sinker seat 8, as well as the common configuration of the needle cams for controlling the knitting mechanism - the needles 7 and the sinker 9 - are well known to those skilled in the art, and Therefore, illustration thereof has been omitted for simplification of description.

[0036] This knitting machine carries a knitting needle cam seat fan-shaped plate carriage 1, and at least one fixed part 2 of this knitting needle cam seat carriage is fixed on the carriage 1 with screws 13, wherein the rib with the bottom plate 6 The movable part 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com