Die blank holder device and application method thereof

A technology of blank holder and mold, which is applied in the directions of feeding device, positioning device, storage device, etc., can solve the problem of inability to accurately control the size of blank holder force, and achieve the guarantee of control effect and stability, prevention of rupture and continuous change. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

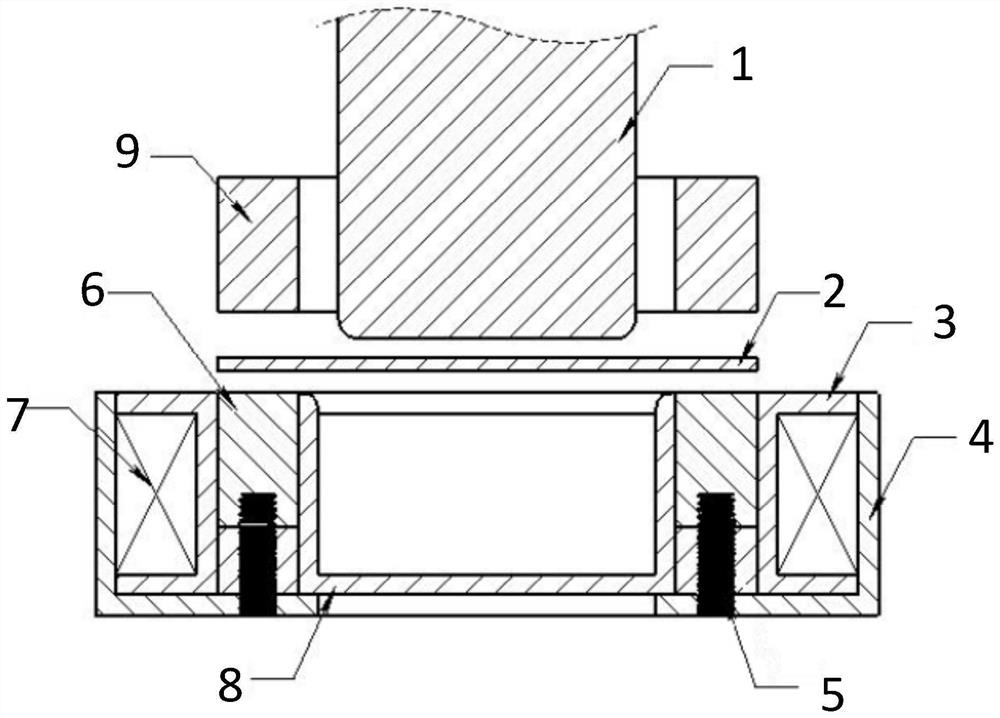

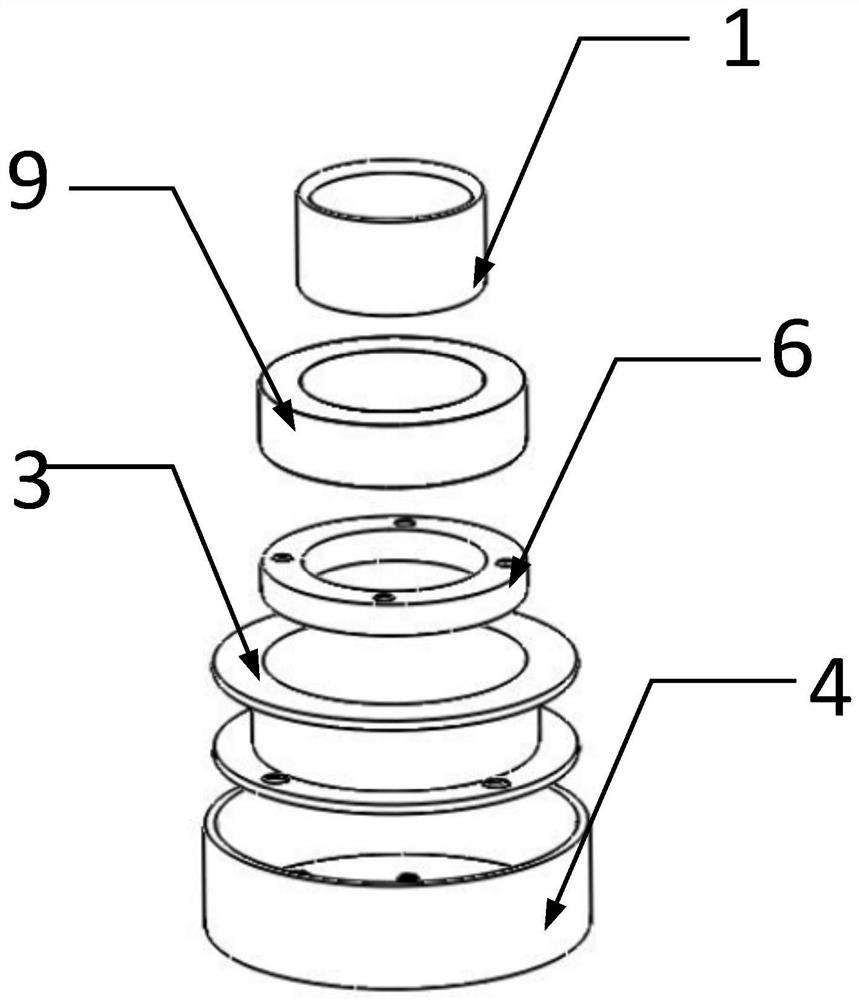

[0031] refer to Figure 1-2 As shown, the present embodiment provides a mold binder ring device, which includes a housing and a mold body disposed in the housing. The mold body includes a punch 1 , a die 8 , a magnetorheological elastomer blank holder 6 , an excitation coil 7 , a coil frame 3 and a permanent magnet 5 .

[0032] Wherein, the excitation coil 7 is wound on the bobbin; the permanent magnet 5 is fixed in the bobbin; A die 8 is arranged inside the magnetorheological elastomer blank holder 6 , and the punch 1 is connected to a stamping mechanism to stamp the plate 2 on the die 8 . Promptly stamping in the cavity of die 8.

[0033] In this embodiment, the magnetic field is generated after the excitation coil 7 is energized; the size of the magnetic field is controlled by using the characteristics of the magneto-rheological elastomer, and the rigidity of the magneto-rheological elastomer binder ring 6 is adjusted to control the magnetorheological elastomer binder rin...

Embodiment 2

[0041] Based on the first embodiment, this embodiment provides an application method of a mold blank holder device. The method comprises the steps of:

[0042] Step S1: When the mold drawing work starts, the excitation coil 7 is passed through current, so that the interior of the coil frame 3 is filled with a magnetic field in the vertical direction, so that the stiffness of the magneto-rheological elastomer blank holder 6 increases under the action of the magnetic field, and in the The vertical direction produces a certain amount of deformation. Further, in this embodiment, the blank-holding force of the magneto-rheological elastomer ring 6 on the plate 2 varies with the magnitude of the current of the exciting coil 7.

[0043] Step S2: Place the plate 2 above the magnetorheological elastomer blank holder 6, the punch 1 moves under the driving force of the stamping mechanism, the punch housing 9 contacts the plate 2, and presses the edge with the magnetorheological elastomer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com