Textile fabric winding device

A rolling device and fabric technology, applied in the field of fabric processing, can solve the problems of inconvenient adjustment of fabric limits of different sizes, inconvenient control of fabric tension, inconvenient fabric surface dust removal, etc., to increase the accommodated volume and prevent position deviation Migration, anti-wrinkle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

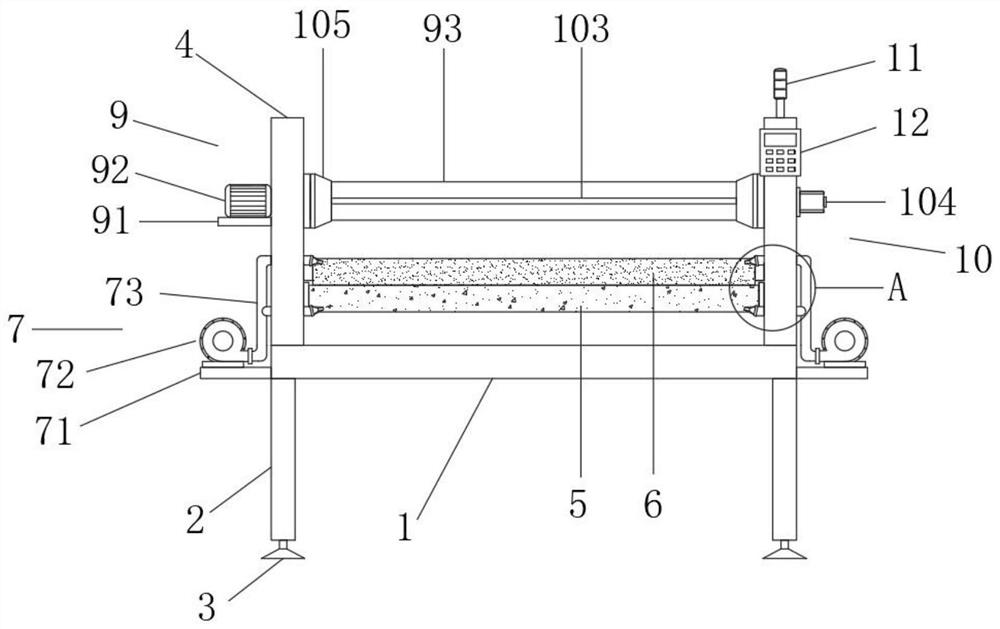

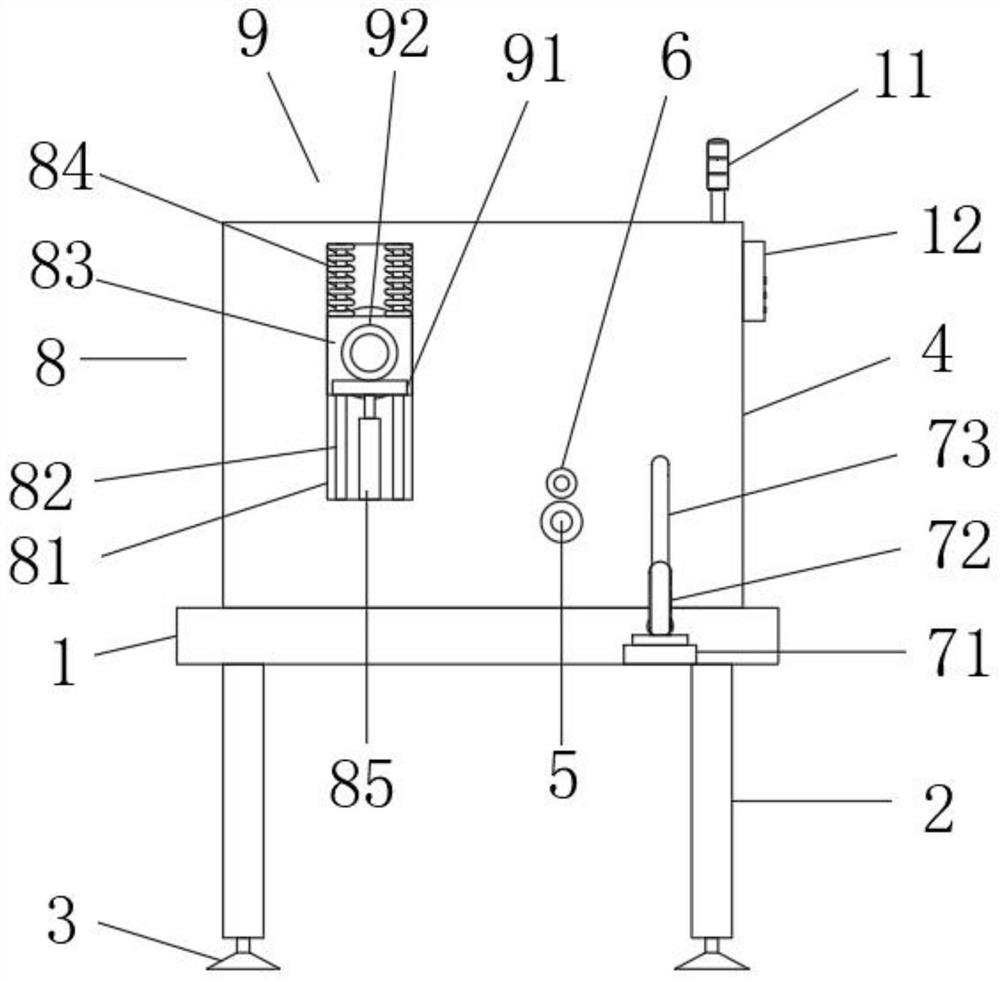

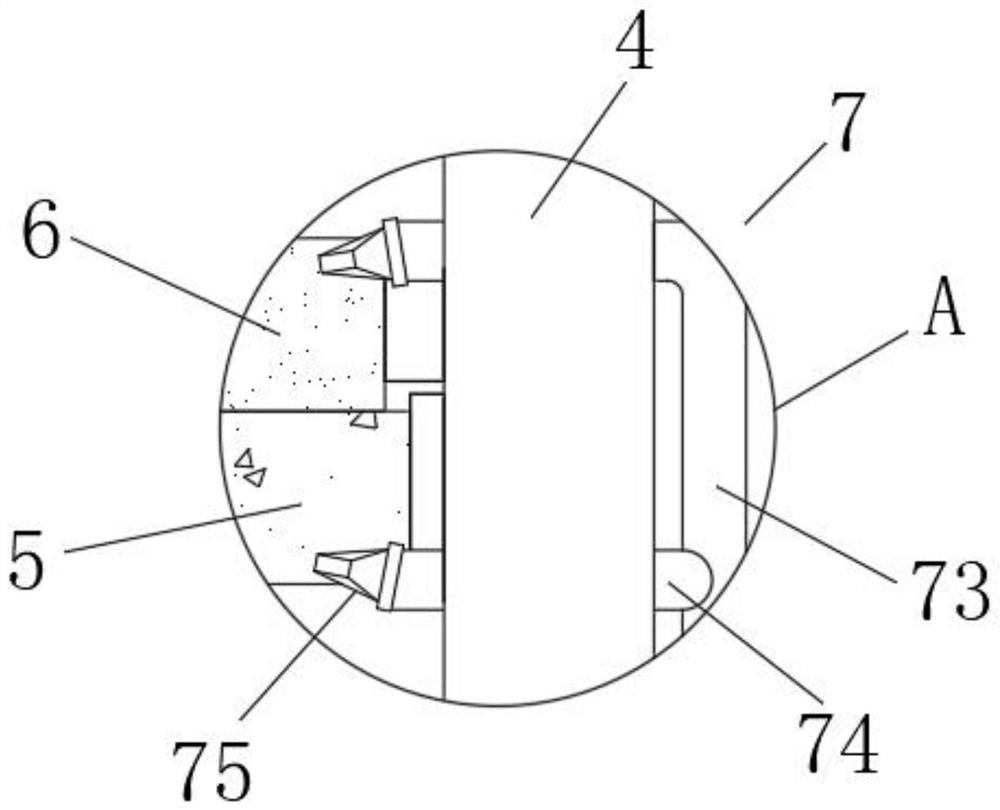

[0024] Such as Figure 1-5 As shown, this specific embodiment adopts the following technical solutions: a fabric rolling device for textiles, including a main table top 1, a dust removal mechanism 7, a lifting mechanism 8, a winding mechanism 9, and an adjustment mechanism 10, and the bottom of the main table top 1 Outriggers 2 are fixedly connected all around, and the bottoms of the legs 2 are fixedly connected with cup-shaped feet 3, which is convenient to make the equipment more stable. The middle part of one of the side plates 4 is rotatably connected with a first guide roller 5, and the middle parts of the two side plates 4 are rotatably connected with a second guide roller 6 above the first guide roller 5, and the second guide rollers 6 and the first guide roller 5 are attached and parallel to each other, so as to guide the textile fabric and limit the speed so as to improve the tension of the fabric. The two sides of the main table 1 are symmetrically equipped with dust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com