Foot-stand mechanism of unmanned aerial vehicle

A technology of unmanned aerial vehicle and tripod, applied in the field of unmanned aerial vehicle, can solve the problems of large space occupied by the tripod, damage of the unmanned aerial vehicle, inconvenient storage, etc., and achieve the effect of being easy to store, not easily damaged, and preventing transmission problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

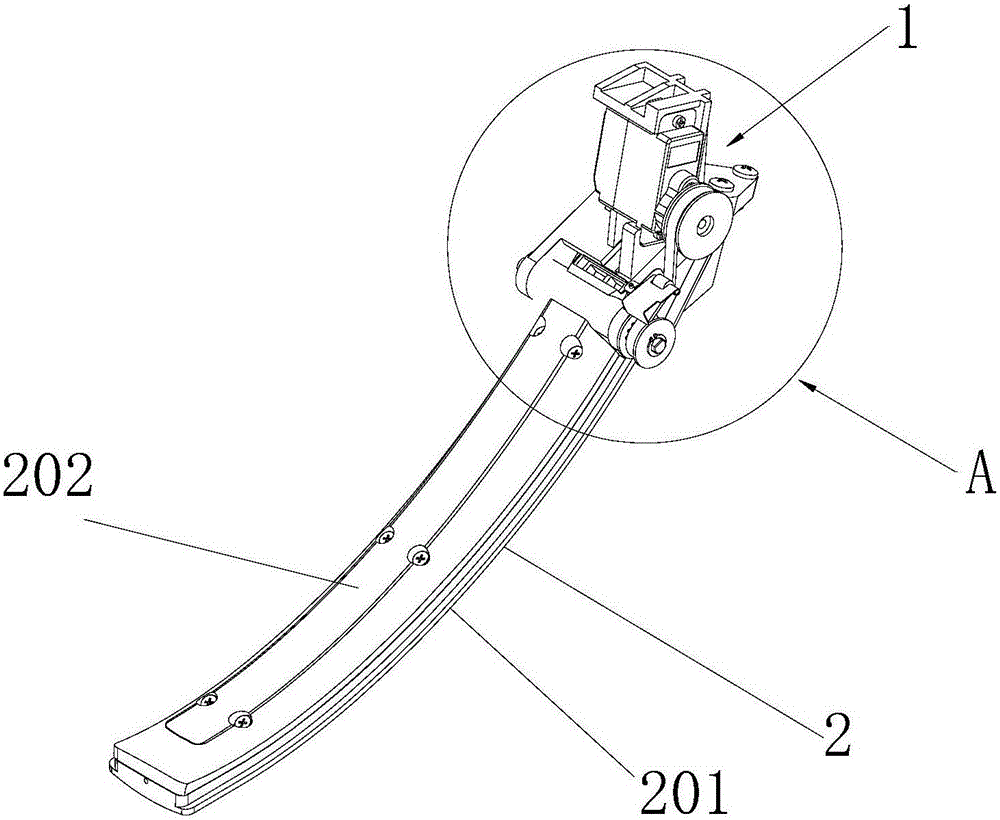

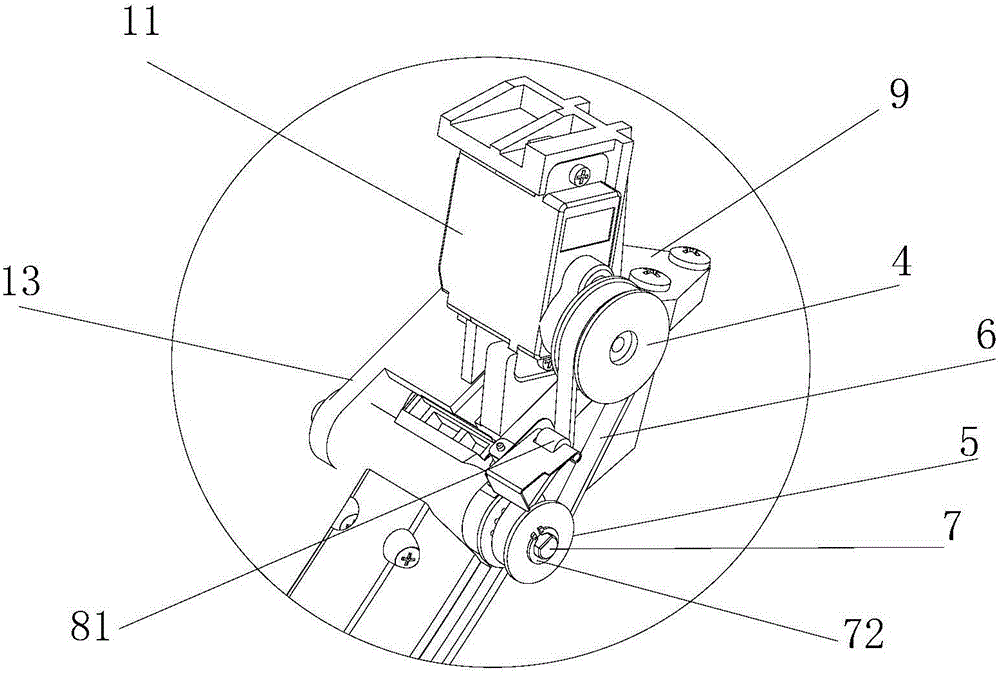

[0032] Such as figure 1 with figure 2 As shown in the schematic diagram of the tripod mechanism, the tripod mechanism of the unmanned aerial vehicle of the present invention includes a stand 1 fixed on the main body of the drone and a stand 2 hinged to the stand 1 and a stand 2 arranged on the stand 1 and The transmission mechanism between the tripods 2 includes: a motor 11 fixed on the support 1, a driving wheel 4 fixedly connected to the motor shaft, and a driven wheel 5 arranged coaxially with the footrest shaft 7. The driving Power is transmitted between the wheel 4 and the driven wheel 5 through a bendable power transmission mechanism to control the extension and recovery of the tripod 2. Preferably, the transmission mechanism is a timing belt transmission mechanism, the bendable power transmission mechanism is a belt 6 provided with cogging, and the driving wheel 4 and the driven wheel 5 are provided with cogging meshing with the belt 6 The driving wheel 4 rotates throu...

Embodiment 2

[0035] Such as figure 1 with figure 2 As shown in the schematic diagram of the tripod mechanism, the connecting arm 13 is provided with a shaft hole, and the tripod 2 is rotatably fixed on the connecting arm 13 through a tripod shaft 7 arranged in the shaft hole. At least one end of the tripod shaft 7 Extending from the outer side of the connecting arm 13. The driven wheel 5 is fixed on the part of the stand shaft 7 located outside the connecting arm 13, and the driving wheel 4 and the driven wheel 5 are located in the same plane. A limit surface is provided on the part of the tripod shaft 7 located outside of the connecting arm 13, and the axis of the driven wheel 5 can be attached to the limit surface and pass through the limit surface to limit it and the tripod shaft 7 During the relative rotation between the two, the tripod shaft 7 and the tripod 2 rotate integrally, and the extension and retraction of the tripod 2 are controlled by this. The tripod shaft 7 is also provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com