Non extensible guide precision displacement platform

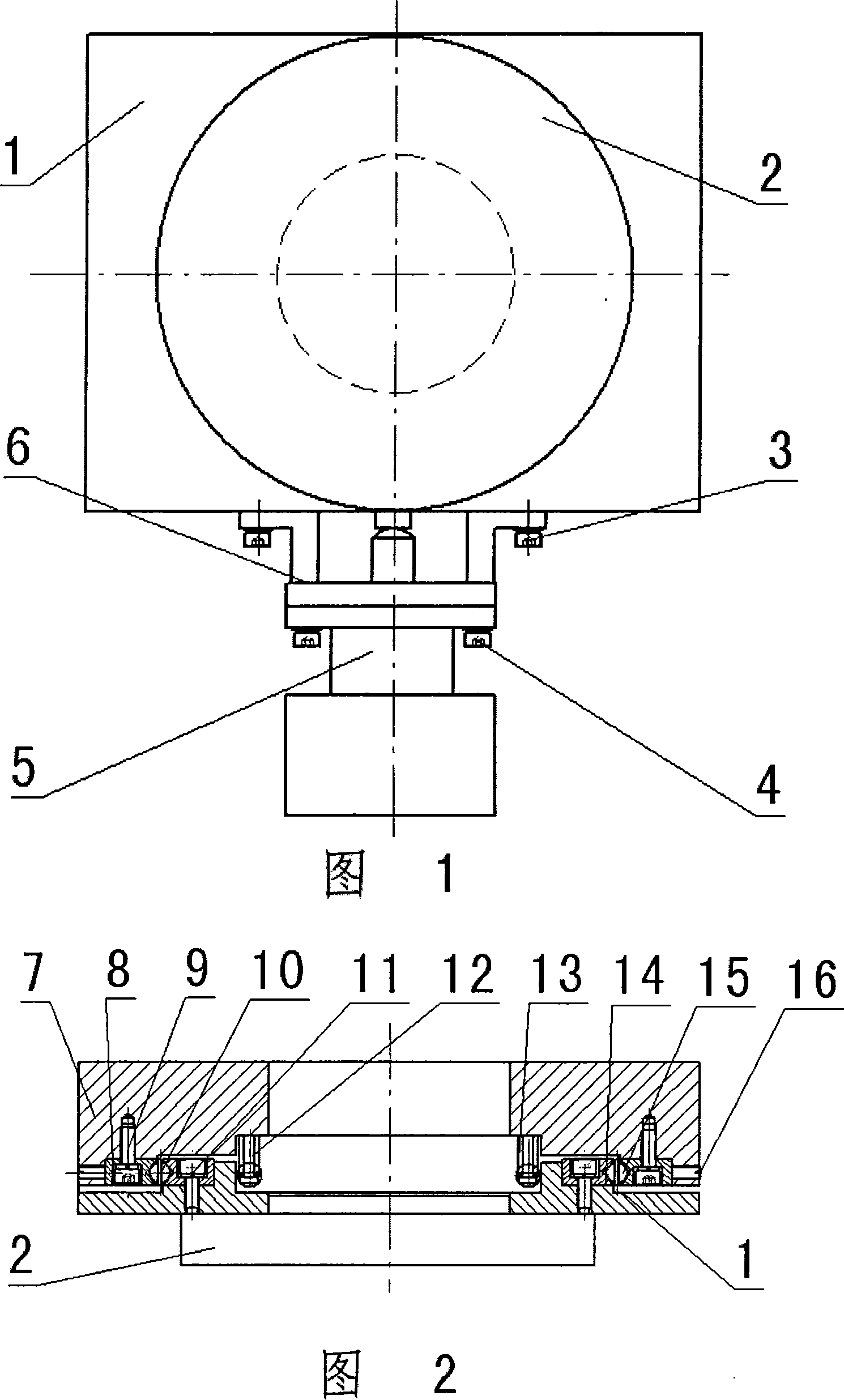

A precision displacement, no guide rail technology, applied to the parts of the instrument, instruments, etc., can solve the problems of small friction of the rolling guide rail, poor displacement straightness, difficult assembly and adjustment, etc., to achieve simple structural parts, low manufacturing cost, The effect of high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

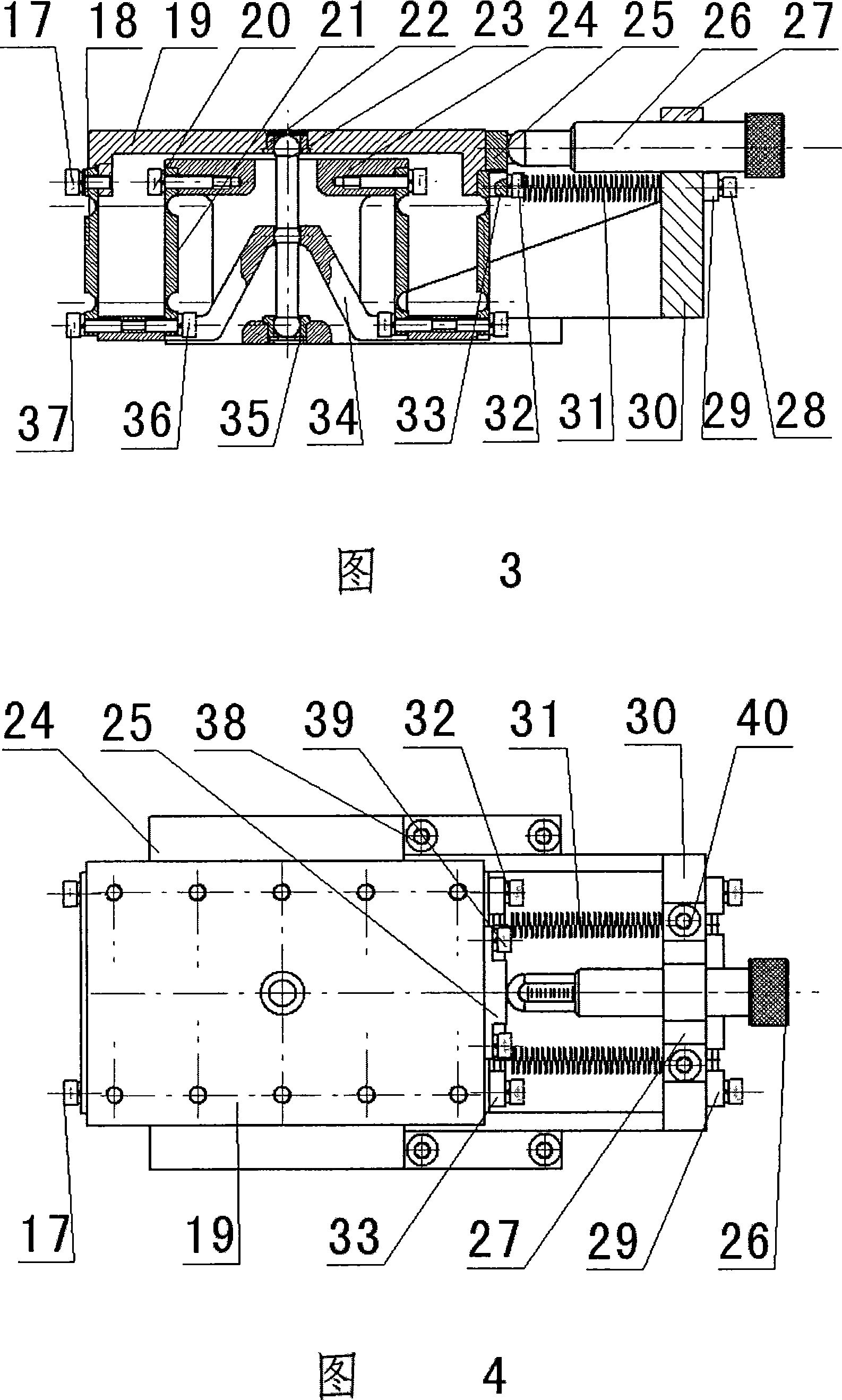

[0027] The present invention is implemented by the structure shown in Fig. 3 and Fig. 4, wherein the material of the first deformed plate 18 adopts 65Mn, and quantity is two, and two deformed plates are equal in length, and the movable table top 19 adopts 45Mn material. # Steel; the second deformed plate 21, the material adopts 65Mn, the quantity is two, and the two deformed plates are equal in length; the upper bushing 22, the material adopts H62, and the inner hole cylinder surface will be ground; the proportional push rod 23, the material adopts 40Cr, two Spherical surfaces are used at the end and in the middle, and the three spherical surfaces are required to be equidistant; the base is 24, and the material is 45 # Steel; drive block 25, material 45 # Steel requires high hardness, and the right side profile and smoothness need to be ground; the drive differential head is purchased, and the model is OA105; the pressure plate is 27, and the material is 45 # Steel; the mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com