Detachable pipe wrench

A technology of pipe wrench and pliers, which is applied in the direction of wrench, wrench, manufacturing tools, etc. It can solve the problems of reducing the clamping effect, immobility, and increasing the workload of the operation, so as to improve the clamping effect, increase the service life, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

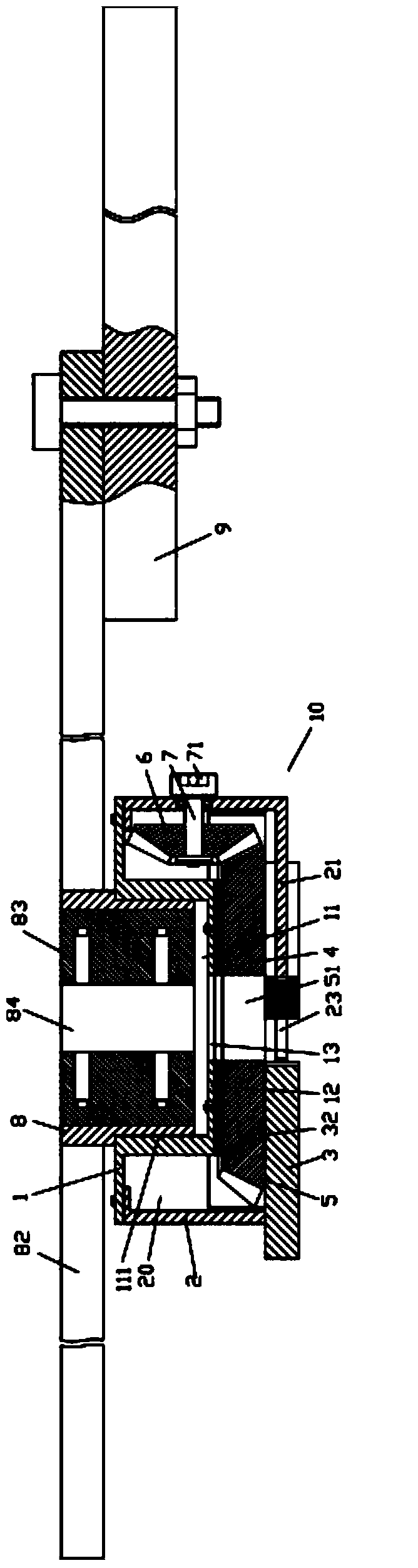

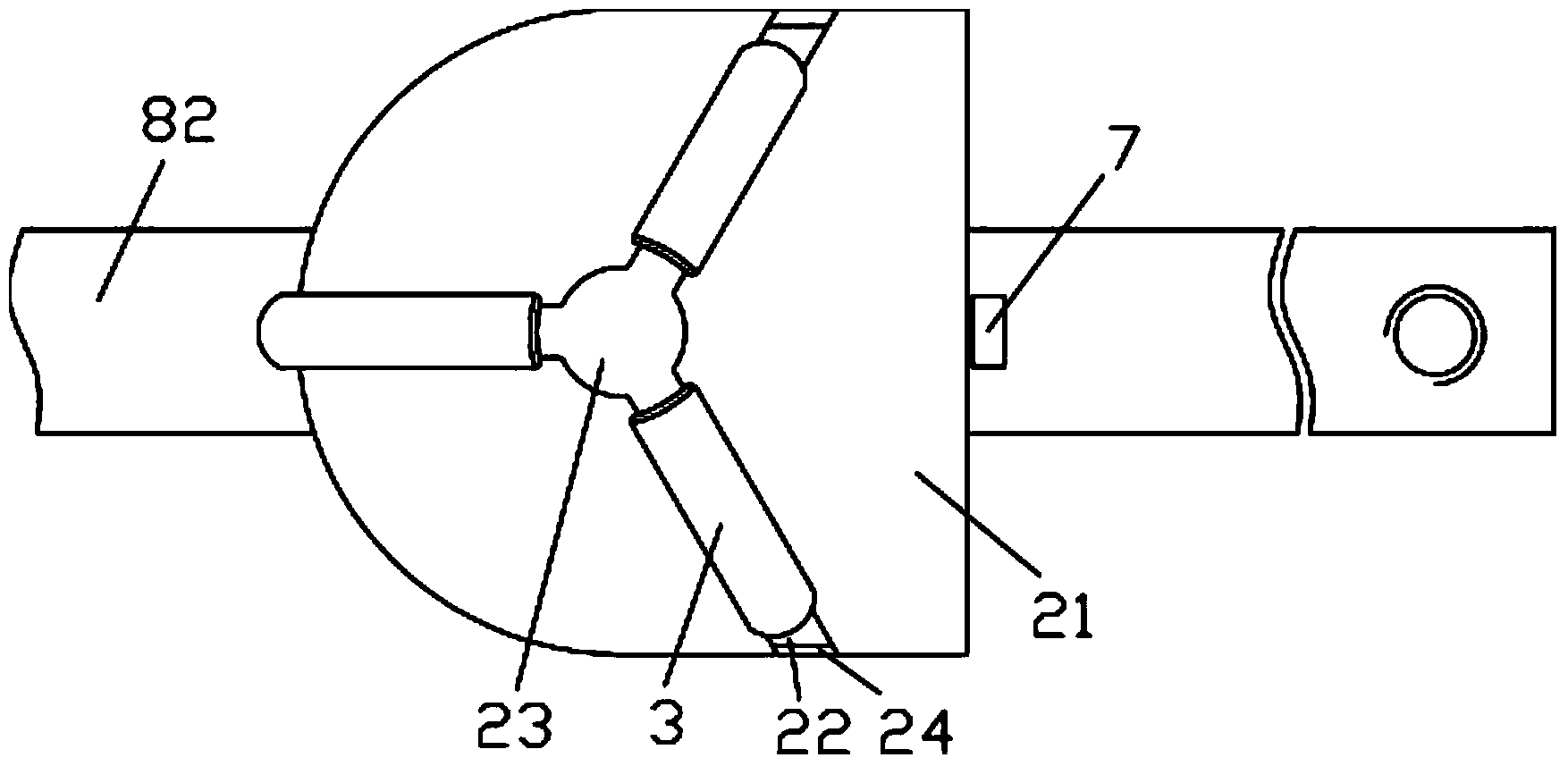

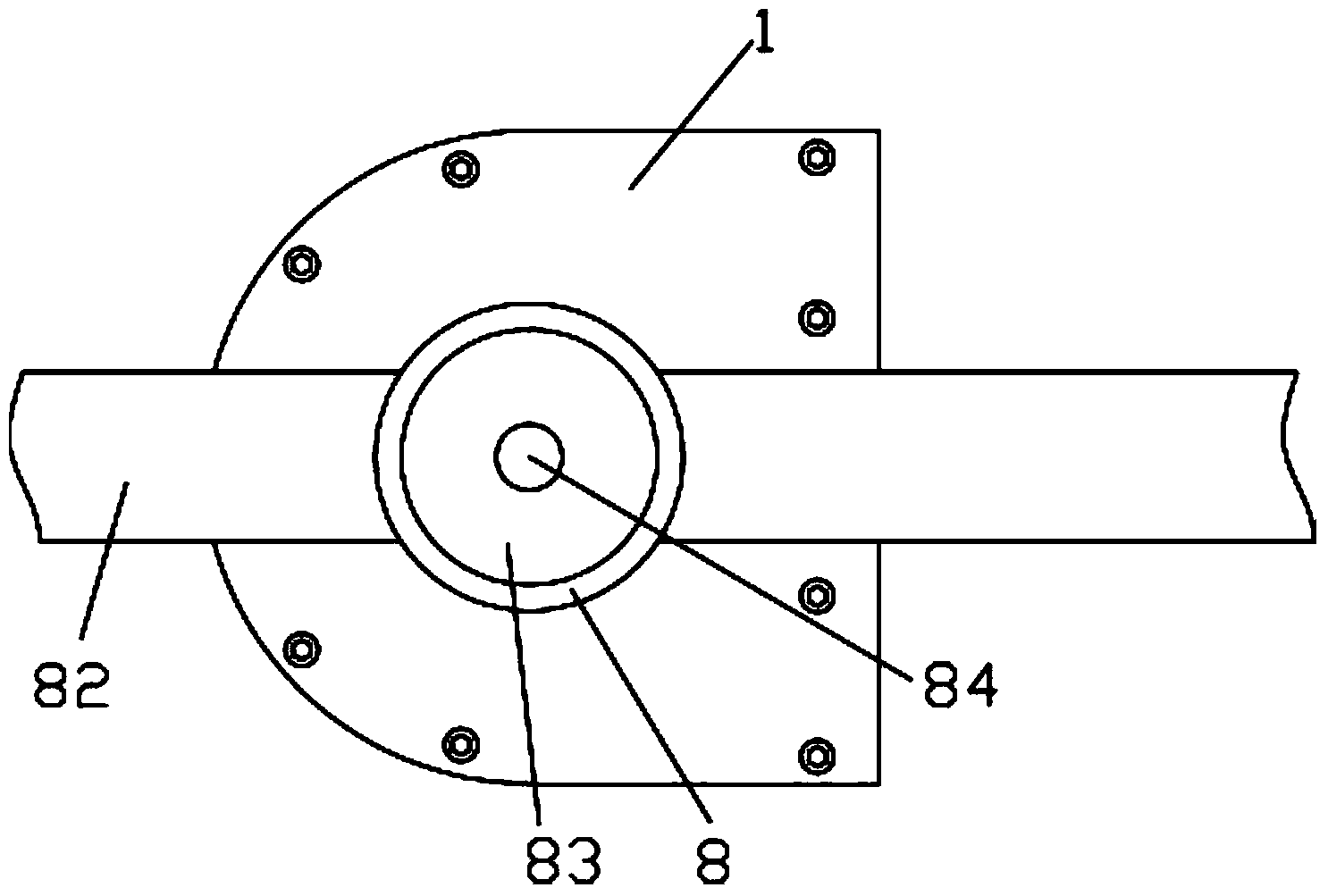

[0024] Example: see Figures 1 to 7 As shown, a detachable pipe wrench includes a pliers body 10, the pliers body 10 includes an upper shell 1 and a lower shell 2, the upper shell 1 is fixedly connected to the lower shell 2 by bolts, and the upper shell 1 and the inside of the lower housing 2 to form a gear cavity 20, the middle part of the upper housing 1 is concaved downward to form a circular groove 11, the upper bottom plate 12 of the circular groove 11 is formed with a circular through hole 13, the lower housing 2 Three elongated through grooves 22 and insertion holes 23 are formed on the bottom plate 21 of the bottom plate, the insertion holes 23 are at the center of the bottom plate 21, and the three elongated through grooves 22 are evenly distributed on the bottom plate 21 with the insertion holes 23 as the center. 23 communicates with each other, the tail end extends outwards and passes through the side of the bottom plate 21, the bottom of the side wall of the lower ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com