Magnetic suspension bearing dynamic torque sensor

A magnetic suspension bearing and dynamic torque technology, which is applied in bearing-related force sensors, force/torque/work measuring instruments, instruments, etc., can solve the problem of unstable performance of dynamic torque sensors, high prices of dynamic torque sensors, and the existence of large-scale promotion. Difficulty and other problems, to achieve the effect of small and sensitive structure, low noise and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

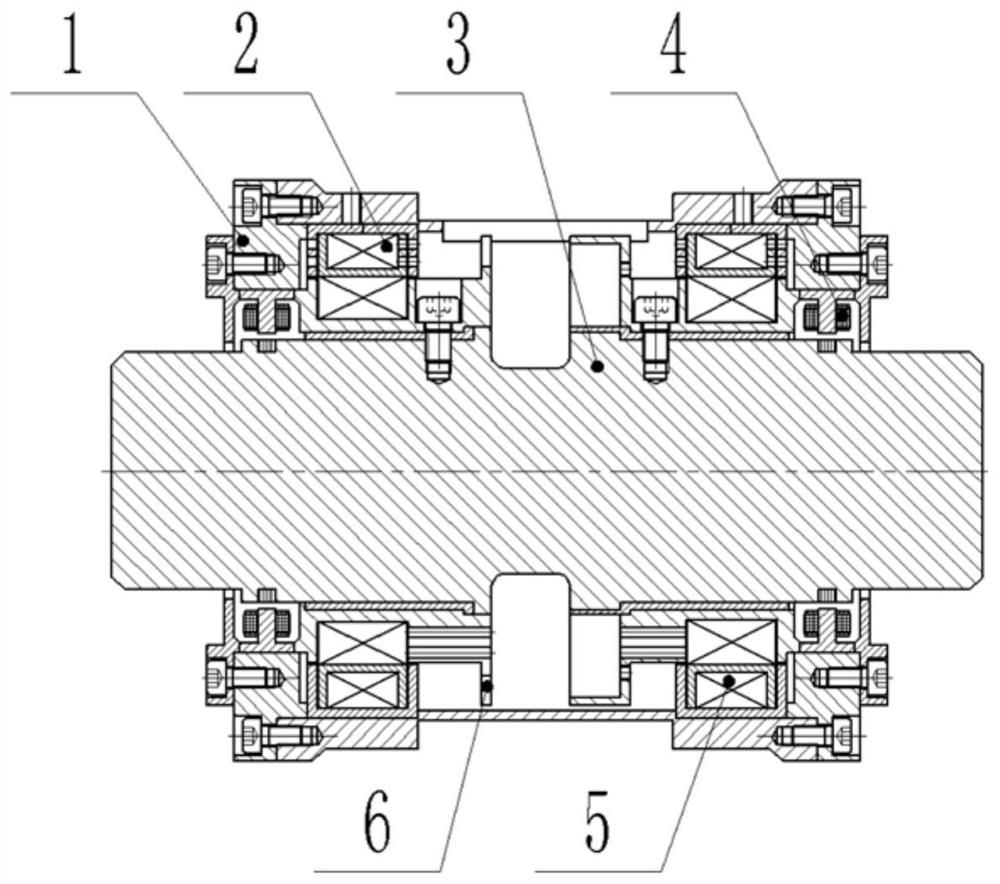

[0026] Such as figure 1 As shown, a magnetic suspension bearing dynamic torque sensor of the present invention is characterized in that it includes: a frame structure part 1, an electric drive part 2, a rotating shaft sensing part 3, a magnetic suspension bearing part 4, a signal processing part 5, and a rotational speed measurement part 6. composition.

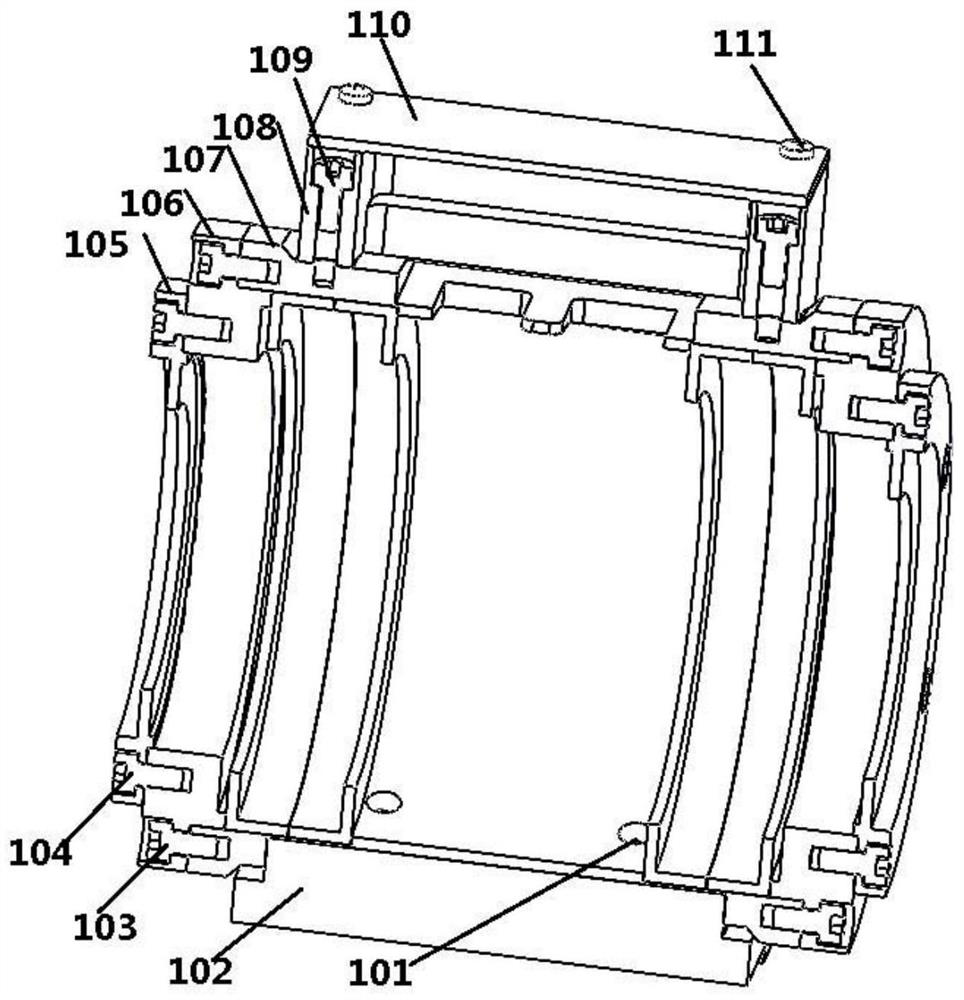

[0027] Such as figure 2 As shown, the frame structure part 1 is the frame of the dynamic torque sensor, which bears the function of fixed connection with the external frame. In order to facilitate processing and assembly, the frame structure is divided into three parts: Body, 108 upper side shell, 102 installation base, and connect with screw 101 and screw 109. The frame structure part undertakes the function of installing the rack, which is realized by the 102 installation base. The frame structure is mostly made of stainless steel, in order to minimize the magnetic circuit interference of the electric drive part. 106 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com