Ultrasonic/sonic wave sampler for drilling

An ultrasonic and sampler technology, which is applied in the field of small drilling samplers, can solve the problems of undiscovered technology and unobtainable technology, and achieve the effect of simple structure, wide application range and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

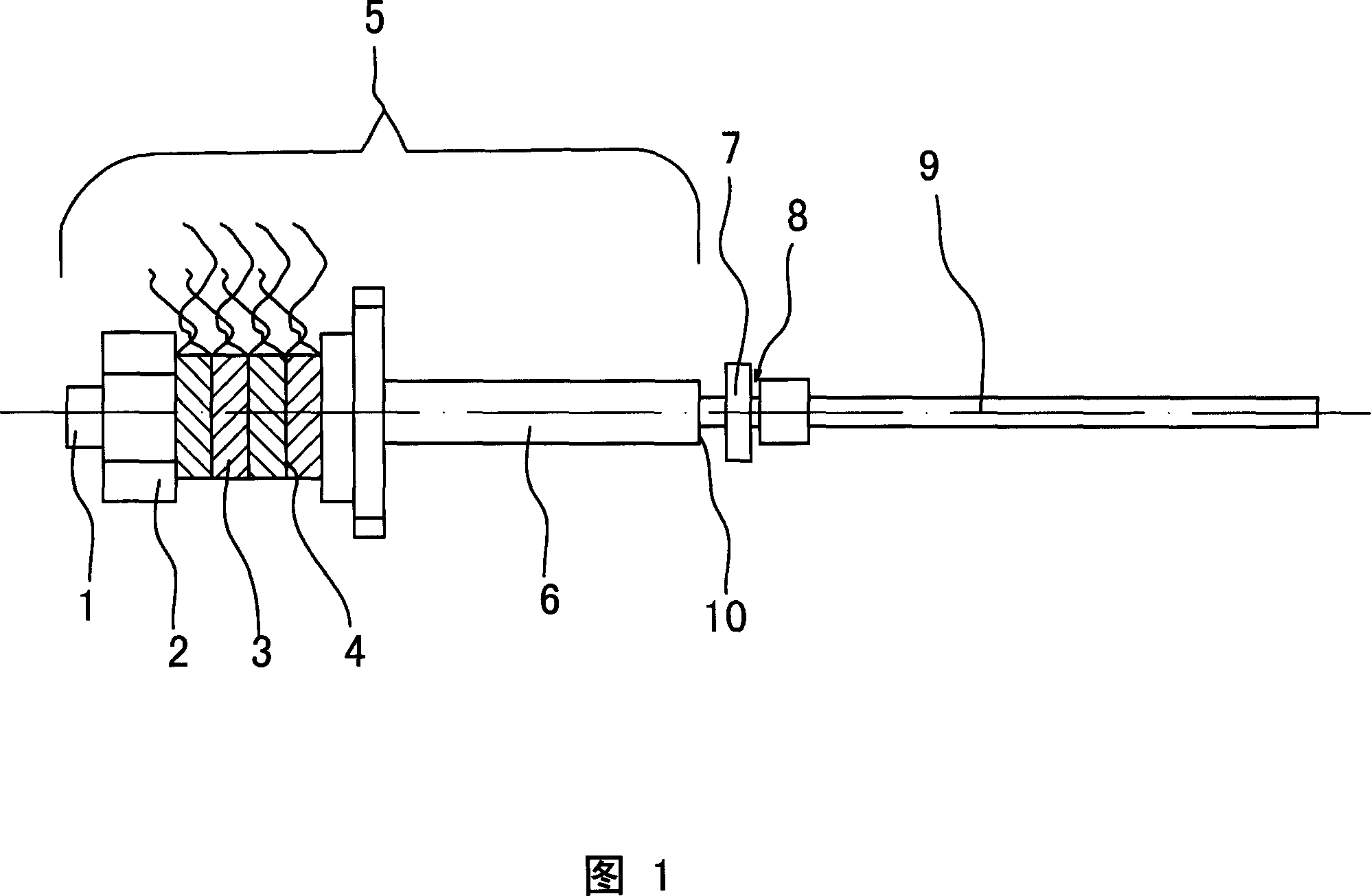

[0022] Example: Referring to Figure 1, the present invention is a new type of ultrasonic / sonic drilling sampler developed based on the first-order longitudinal vibration excited by the piezoelectric effect of a piezoelectric ceramic sheet. The device is composed of three parts: an ultrasonic driver 5, a free mass 7 and a solid drill rod 9. The ultrasonic driver 5 is a Ranjven vibrator, which is composed of a head 6, a tail 2, four piezoelectric ceramic plates 3, and five electrode plates 4, wherein the piezoelectric ceramic plate 3 and the electrode plates The arrangement of 4 is: four piezoelectric ceramic pieces 3 are stacked on the same polarity side in the axial direction (for example, the first one is opposite to the second positive electrode, the second one is opposite to the third negative electrode, and the third Opposite the fourth positive pole; or vice versa, the first one opposes the second negative pole, the second opposes the third positive pole, and the third oppose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com