An adapter for a scrolling component and a scrolling component including that adapter

A technology of adapters and components, which is applied in vehicle parts, transportation and packaging, tire parts, etc., can solve the problems of plastic deformation of adapters, lack of inspiration in literature, damage to rolling components, etc., and achieve the effect of increasing the mechanical stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

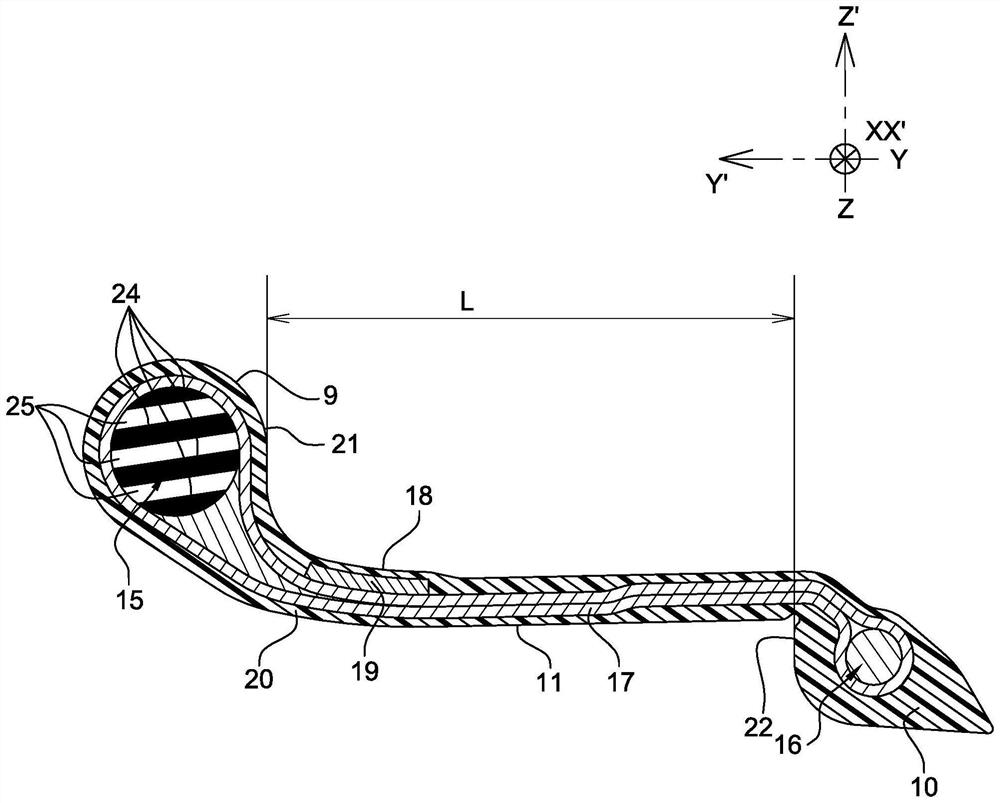

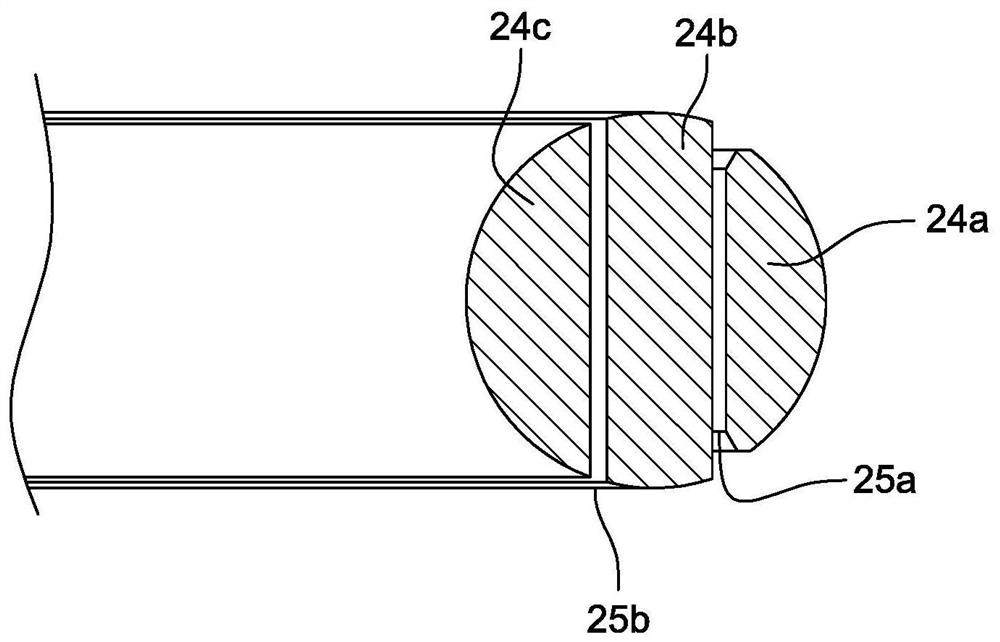

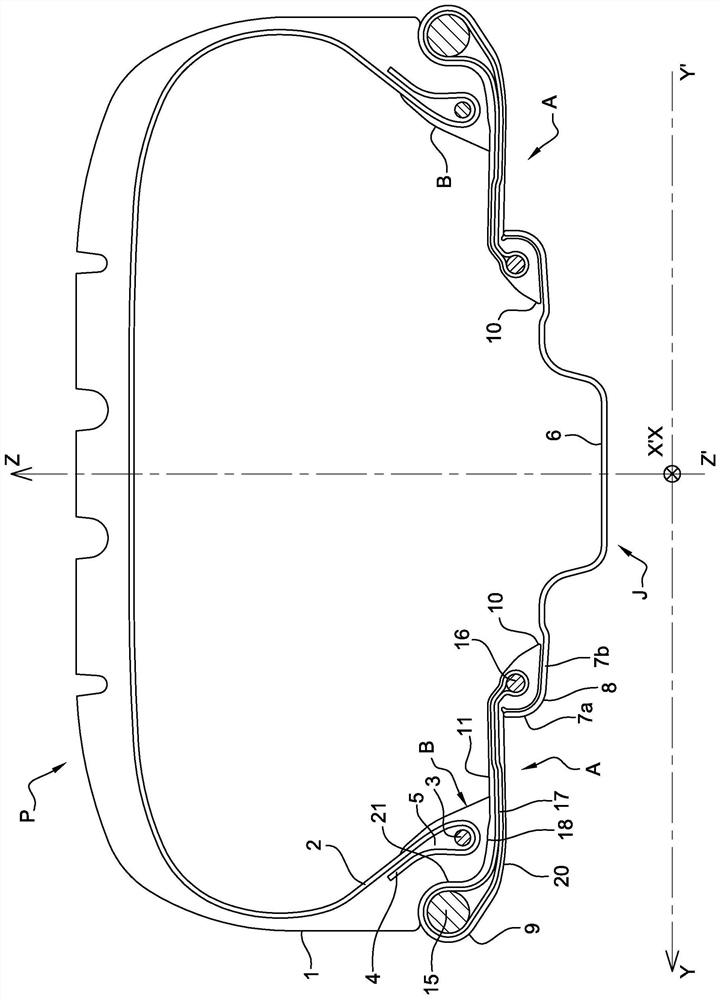

[0038] figure 1 A first alternative form of the adapter according to the invention is shown not mounted on the rim. The adapter comprises an axially outer end 9 comprising an outer reinforcing element 15, an axially inner end 10 comprising an inner reinforcing element 16, and a body 11. The main body 11 includes main reinforcements 17 . The main reinforcement 17 consists of a single reinforcement layer wound around the inner reinforcing element 16 of the axially inner end 10 and around the outer reinforcing element 15 of the axially outer end 9 , respectively. In the body 11 , the main part and the return part of said reinforcement layer thus constitute a substantially radial stack of at least two reinforcement layers. The primary reinforcement 17 is encapsulated in a layer of rubber compound 20 . The body 11 further comprises an adapter seat 18 intended to come into contact with the tire bead. The main body 11 has an axial width L measured between the axially inner surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com