Two-stage rigidity elastic body combination device

A combined device and elastic body technology, applied in the direction of a spring assembly composed of several springs, a device for lateral relative movement between the spring, the chassis and the bogie, etc. Train derailment, reducing the effect of buffering and vibration reduction, etc., to achieve the effect of improving vehicle dynamics, alleviating vehicle wheel-rail impact, and scientific principles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

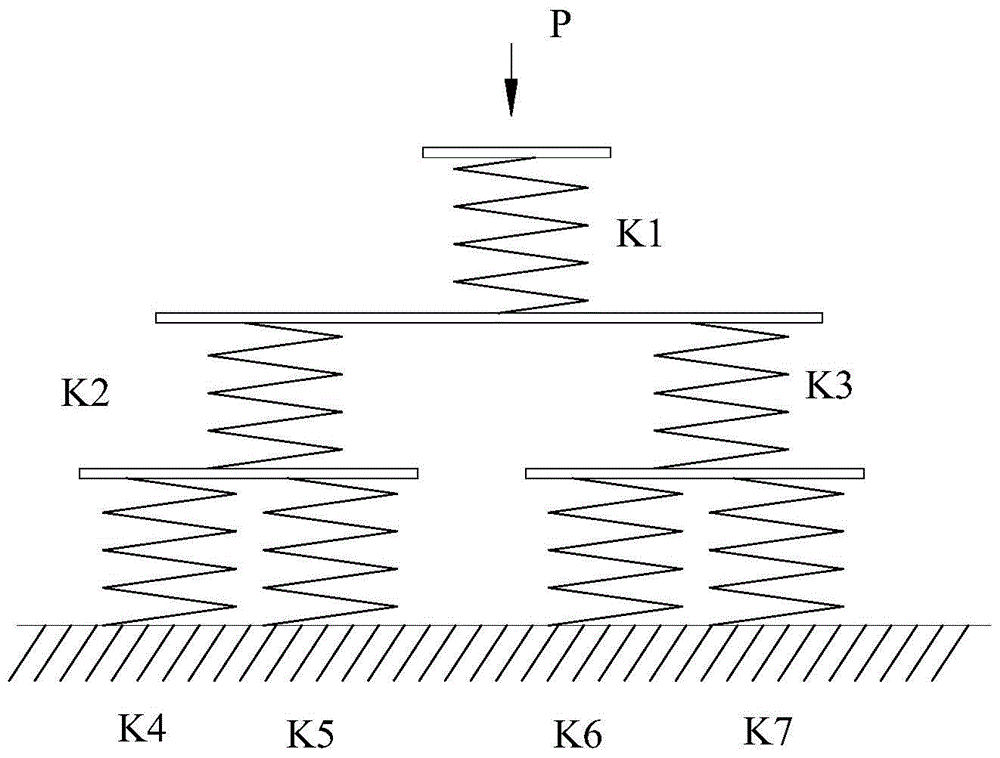

[0042] Such as Figure 4 As shown, the first two-stage rigidity elastic body combination device of the present invention is installed between the side frame pedestal 4 of the railway vehicle bogie and the front and rear sides of the axle box bearing saddle 5, and it has a small rigidity elastic element 1 and an elastic element 2 with large stiffness, elastic element 1 with small stiffness is arranged in the elastomer pre-compression device 3, and is arranged in series with the elastic element 2 with large stiffness under the action of pre-compression load F1.

[0043] Such as Figure 5 As shown, the large-rigidity elastic element 2 has an elastic rubber base layer 2a, and the elastic rubber base layer 2a is sandwiched between two metal bearing plates 2b and vulcanized with them to form a whole. The elastomer pre-compression device 3 has a rigid outer cover 3a, and a guide positioning screw 3b is arranged axially in the rigid outer cover 3a, and one end of the guide positionin...

Embodiment 2

[0048] Such as Figure 6 As shown, the structure of the second two-stage rigidity elastic body combined device of the present invention is the same as that of the first type, except that the small rigidity elastic element 1 is different. . The small-rigidity elastic element 1 has a cylindrical laminated rubber layer 1b which is integrally vulcanized and formed by interlacing multi-layer metal sheets and multi-layer rubber sheets. The cylindrical laminated rubber layer 1b is set on the guide positioning screw 3b. One end of the cylindrical laminated rubber layer 1b is in contact with one of the metal bearing plates 2b, and the other end of the cylindrical laminated rubber layer 1b is in contact with the bottom surface of the rigid outer cover 3a. The cylindrical laminated rubber layer 1b is in a precompressed state under the action of a precompressive load F1 after the lock nut 3c is tightened.

Embodiment 3

[0050] Such as Figure 7 The structure of the third type of two-stage rigidity elastic body combined device shown is the same as that of the first type, except for the small rigidity elastic element 1 . The small rigidity elastic element 1 has a metal coil spring 1c, the metal coil spring 1c is set on the guide positioning screw 3b, one end of the metal coil spring 1c is in contact with one of the metal bearing plates 2b, and the other end of the metal coil spring 1c is in contact with the bottom surface of the rigid outer cover 3a Abut. The metal coil spring 1c is in a precompressed state under the action of a precompressed load F1 after the lock nut 3c is tightened.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com