A Titanium Alloy Geometric Lock Knee Joint

A knee joint, titanium alloy technology, applied in artificial legs and other directions, can solve problems such as instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

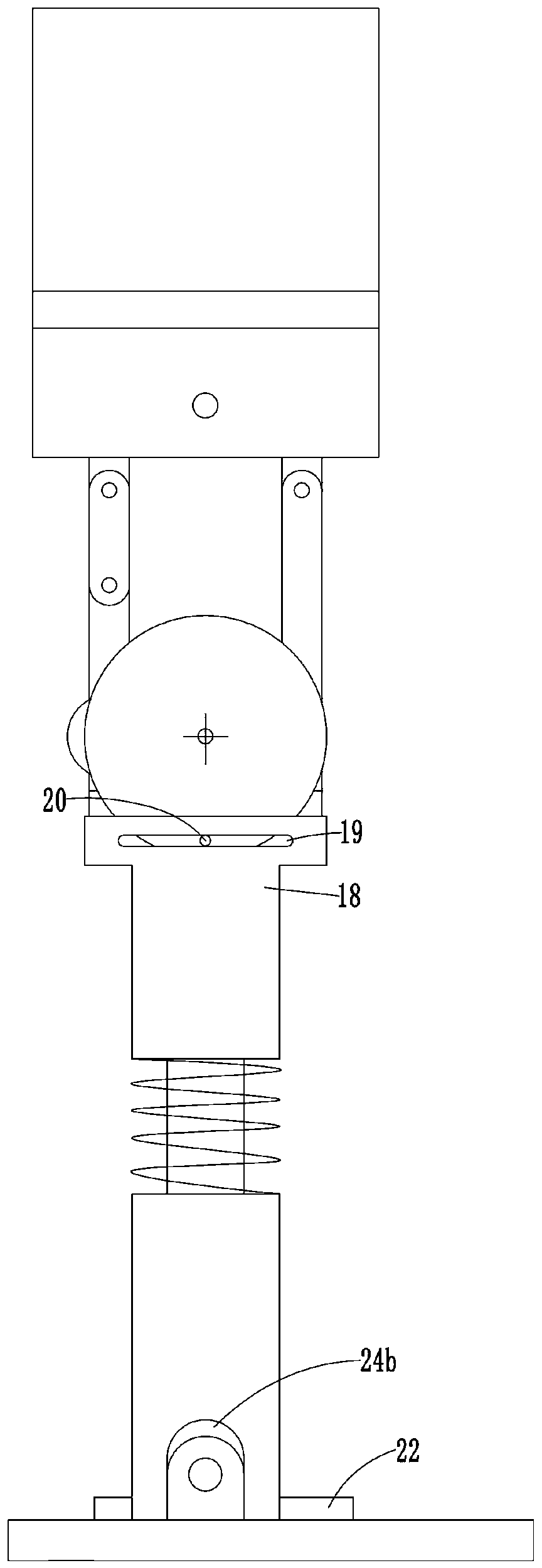

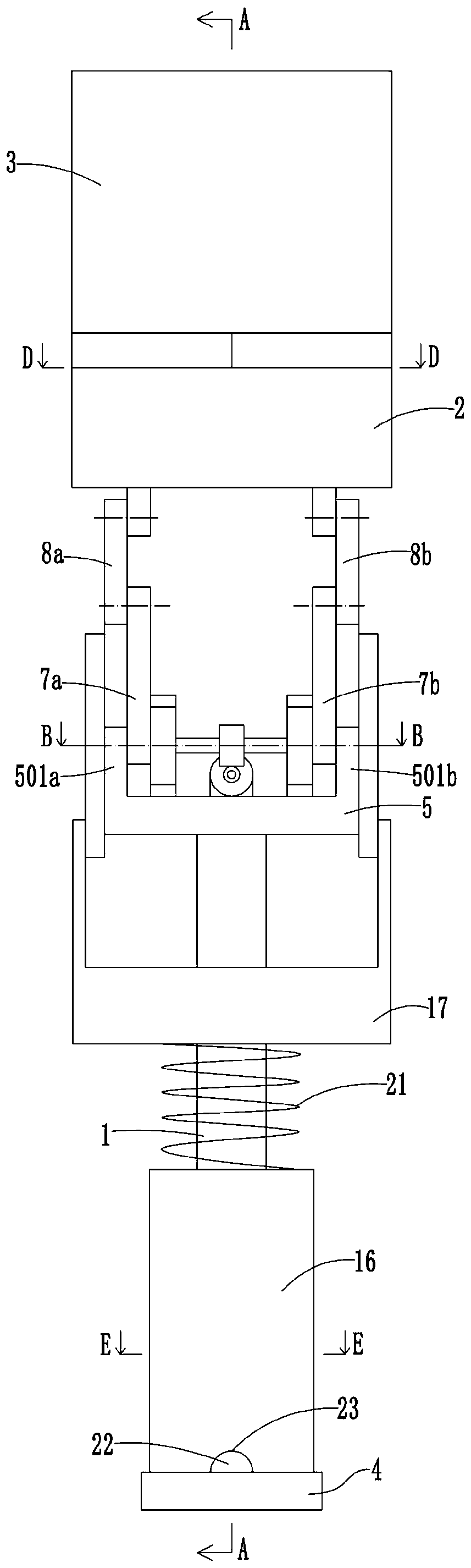

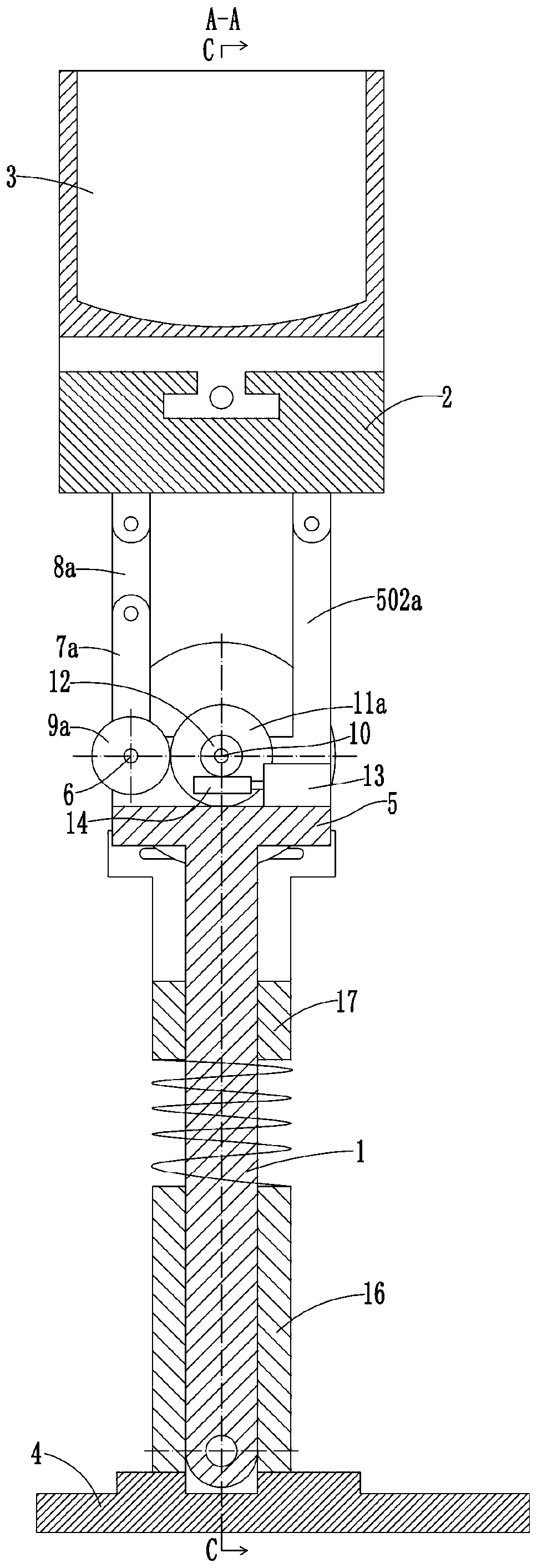

[0032] see Figure 1-11 As shown, a titanium alloy geometric lock knee joint includes a calf plate 1, an upper knee seat plate 2, and a thigh sleeve 3. The lower end of the calf plate 1 is hinged with a foot plate 4, and the upper end is provided with a knee seat plate 5. The left and right sides of seat plate 5 are respectively provided with left side board 501a and right side board 501b, and one end of described left side board 501a is provided with left support board 502a along the length direction of calf board 1, and one end of right side board 501b is along the length direction of calf board 501b. The length direction of the plate 1 is provided with a right support plate 502b, the above-knee seat plate 2 is hinged on the upper ends of the left support plate 502a and the right support plate 502b, and the thigh sleeve 3 is installed on the lap seat plate 2; Between the plate 501a and the right side plate 501b, a first rotating shaft 6 is rotatably connected at one end away...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com