Crankshaft intersecting oil hole deburring tool and using method thereof

A technique for removing hair and oil holes, which is applied in the field of tools for removing burrs from intersecting oil holes of crankshafts, can solve the problems of affecting the life of the crankshaft, high cost, easy corrosion, etc., and achieves the effect of improving deburring efficiency, simple production and easy promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with the accompanying drawings, the present invention will be specifically described with embodiments.

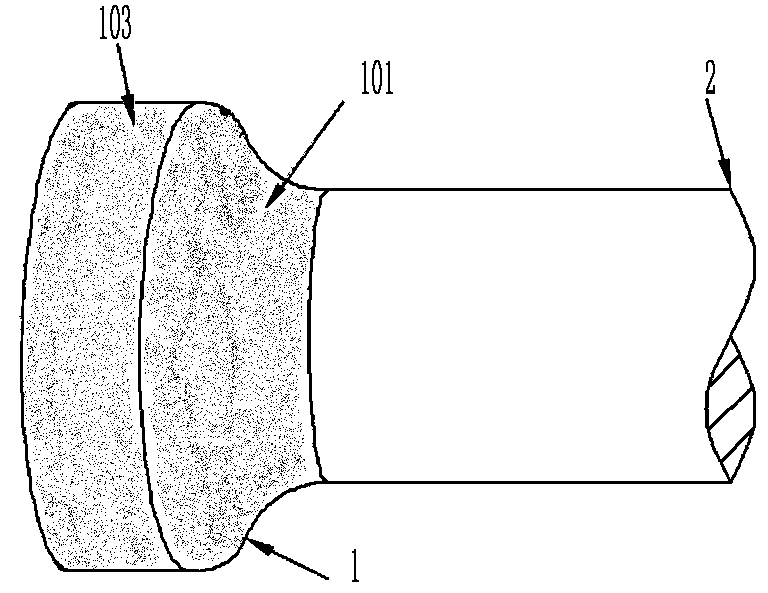

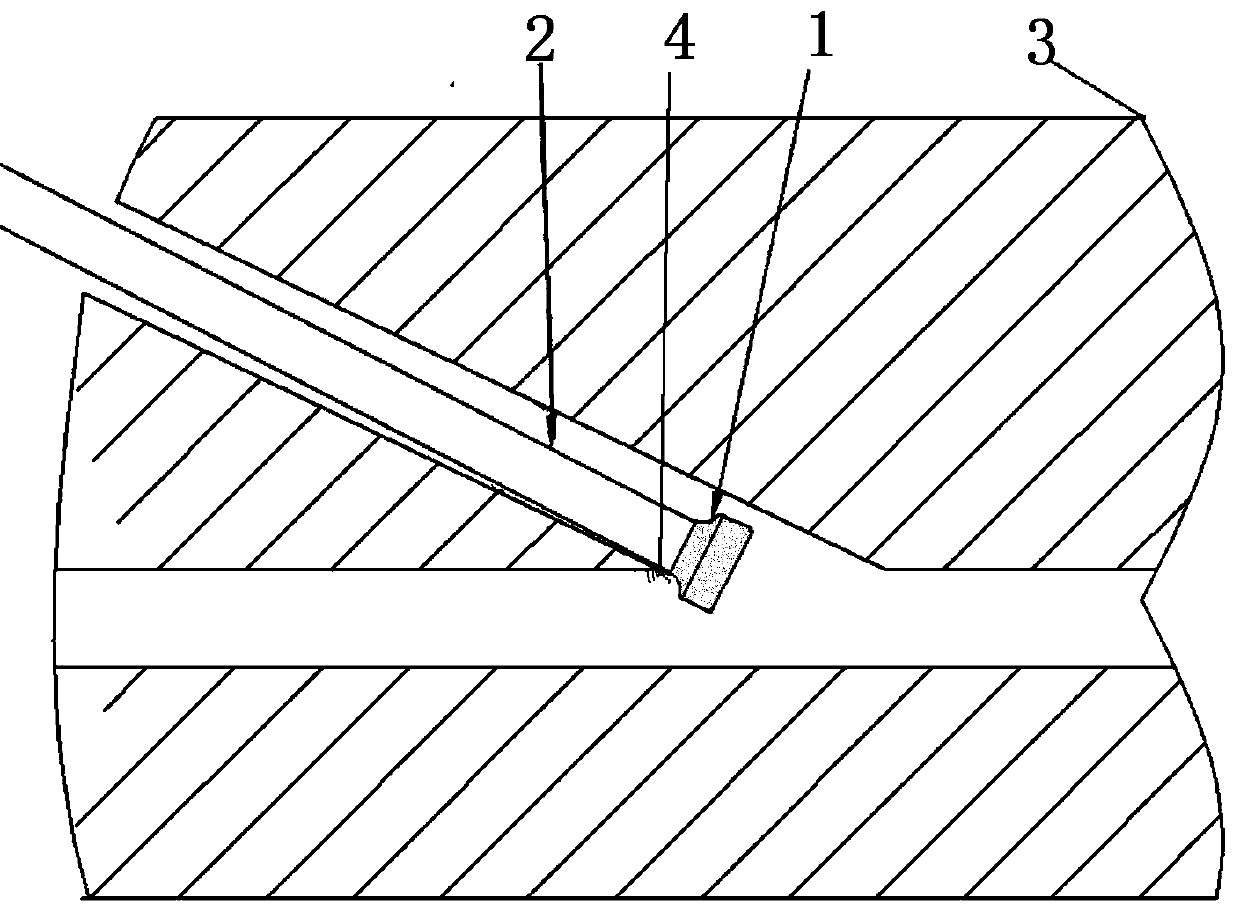

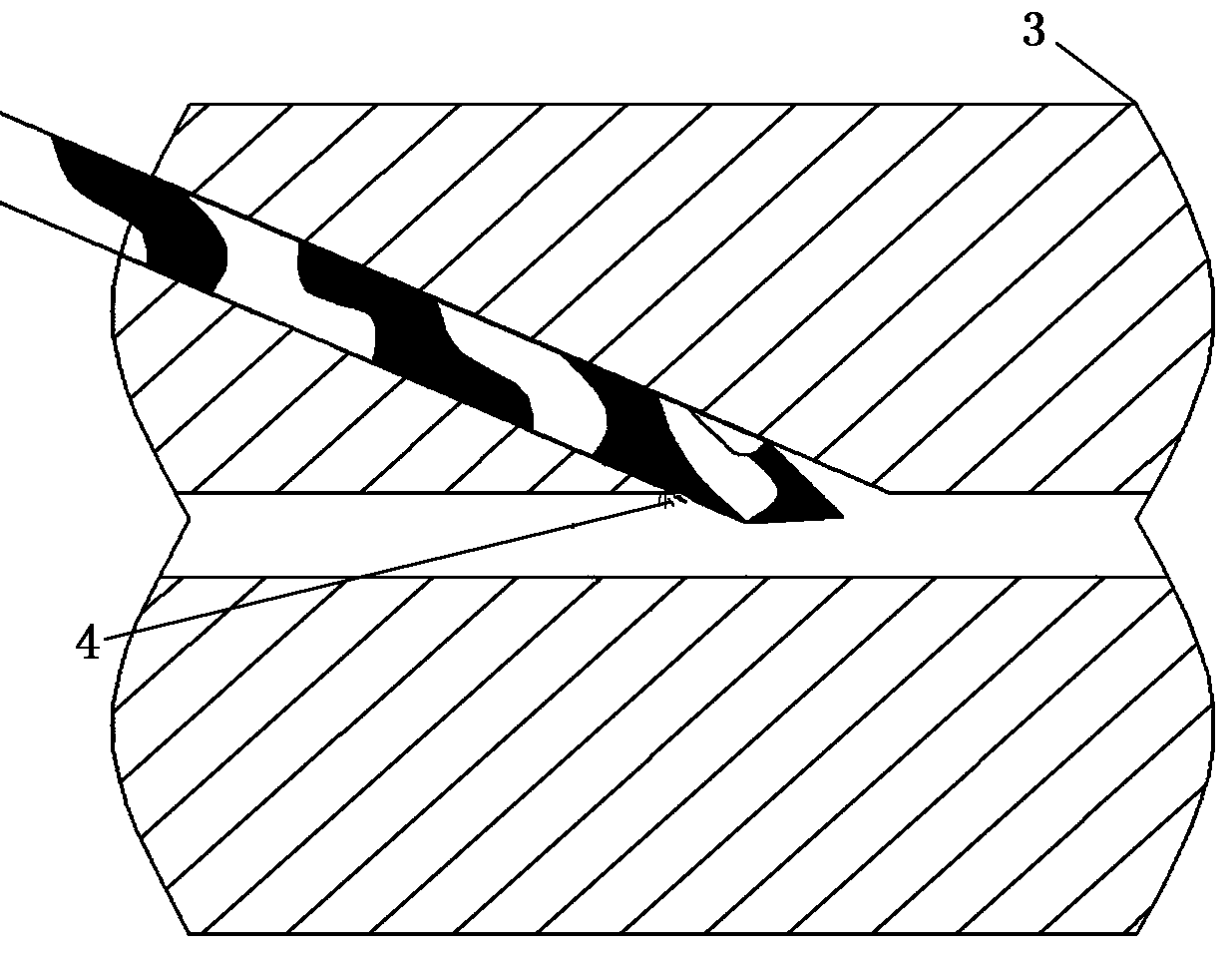

[0022] refer to figure 1 , a tool for removing burrs from crankshaft intersecting oil holes, comprising a cylindrical cutter bar 2 and a cutter head 1 arranged at one end of the cutter bar 2,

[0023] Cutter head 1 is made up of cylindrical cutter body 103 and concave curved surface cutter body 101, and the axis of cylindrical cutter body 103 coincides with the axis of cutter bar 2, and the radius of cylindrical cutter body 103 is greater than cutter bar 2 radius, and the cylindrical surface of cylindrical cutter body 103 is One end of the concave curved cutter body 101 is connected to the cylindrical cutter body 103, and the other end is connected to the cutter bar 2. The concave curved cutter body 101 is surrounded by two end faces and the working curved surface between the two end faces. The working curved surface is a concave rotating surfa...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap