A flange positioning fixture

A technology for positioning fixtures and positioning discs, which is used in positioning devices, clamping, manufacturing tools, etc., and can solve problems such as low processing quality, poor flange stability, and random teeth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

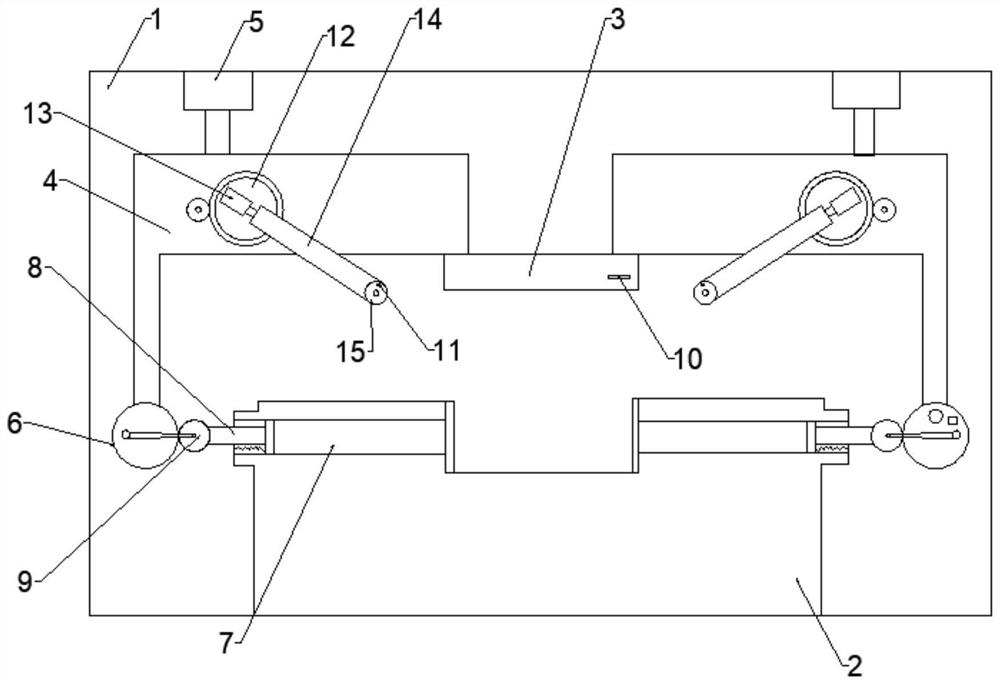

[0021] A flange positioning fixture of the present invention will be described in more detail below in conjunction with schematic diagrams, wherein a preferred embodiment of the present invention is shown, and it should be understood that those skilled in the art can modify the present invention described here and still realize the present invention beneficial effect. Therefore, the following description should be understood as the broad knowledge of those skilled in the art, but not as a limitation of the present invention.

[0022] Such as figure 1 As shown, a flange positioning fixture includes a frame 1 and a control cabinet; the frame 1 is provided with a positioning plate 2, and the positioning plate 2 is provided with a positioning groove, and the frame 1 above the positioning groove is connected with a vertical Sliding ring pressure plate 3, frame 1 is provided with two pressing devices that are centered symmetrically with ring pressure plate 3; Drive the first drive...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap