Carrying platform used for transferring of flexible screens

A technology for carrying platforms and screens, applied to conveyor objects, furnaces, lighting and heating equipment, etc., can solve problems such as high cost and lack of versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

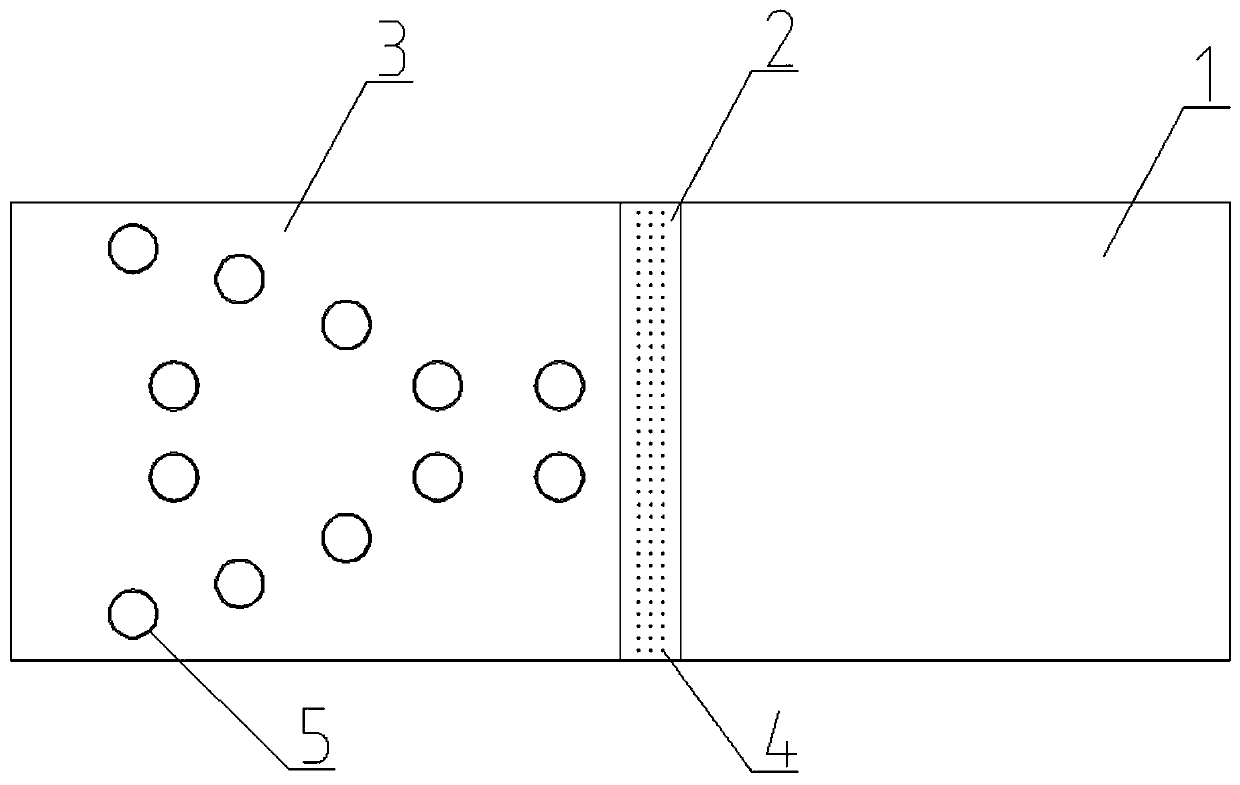

[0024] Such as figure 1 as shown, figure 1 It is a structural view of the flexible screen conveying and carrying platform; the flexible screen conveying and carrying platform of the present invention is provided with an FPC support part 1, a terminal absorbing part 2 and a screen absorbing part 3 along the length direction, and the terminal absorbing part 2 is provided with Between the FPC support part 1 and the screen body adsorption part 3; on the same end face of the flexible screen conveyance platform, the terminal adsorption part 2 is evenly distributed with a number of first adsorption holes 4, the screen The body adsorption part 3 is provided with a number of second adsorption holes 5, the first adsorption holes 4 are used to adsorb the connecting part of the screen body of the flexible screen and the FPC, and the second adsorption holes 5 are used to adsorb the screen body of the flexible screen After the first adsorption hole 4 and the second adsorption hole 5 adsorb...

Embodiment 2

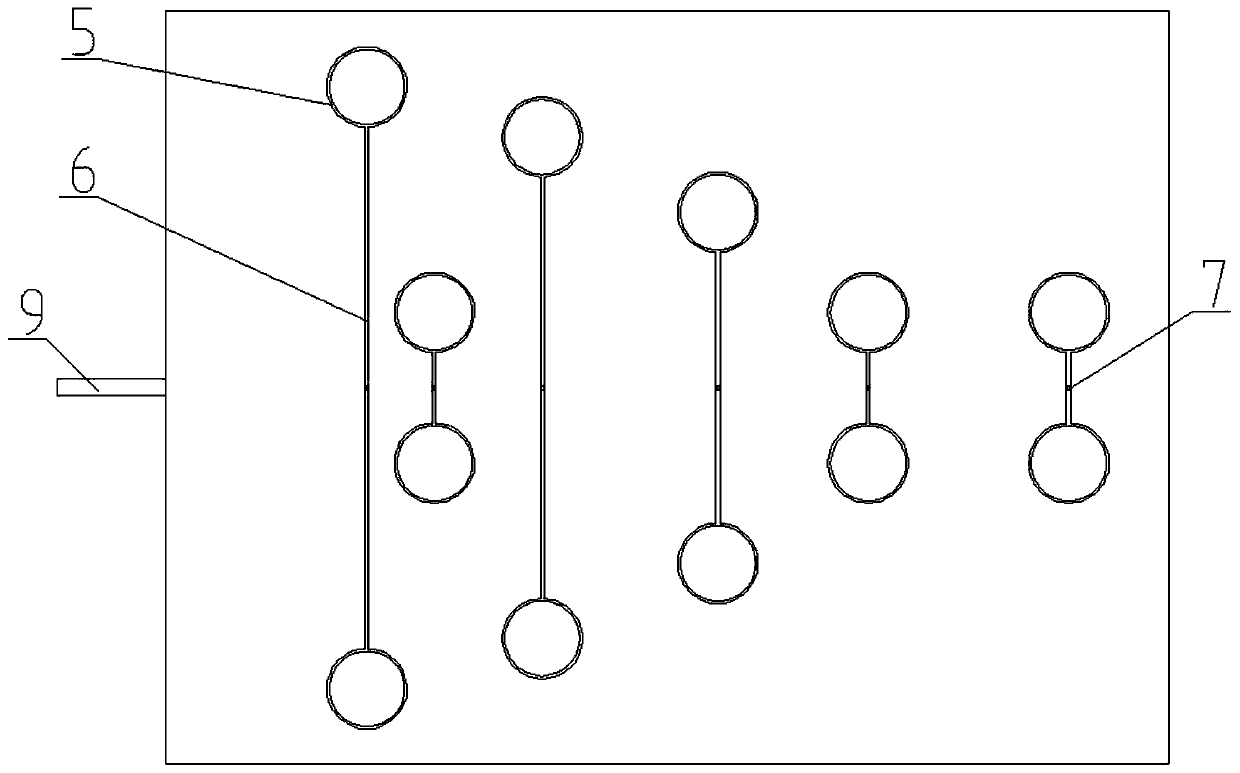

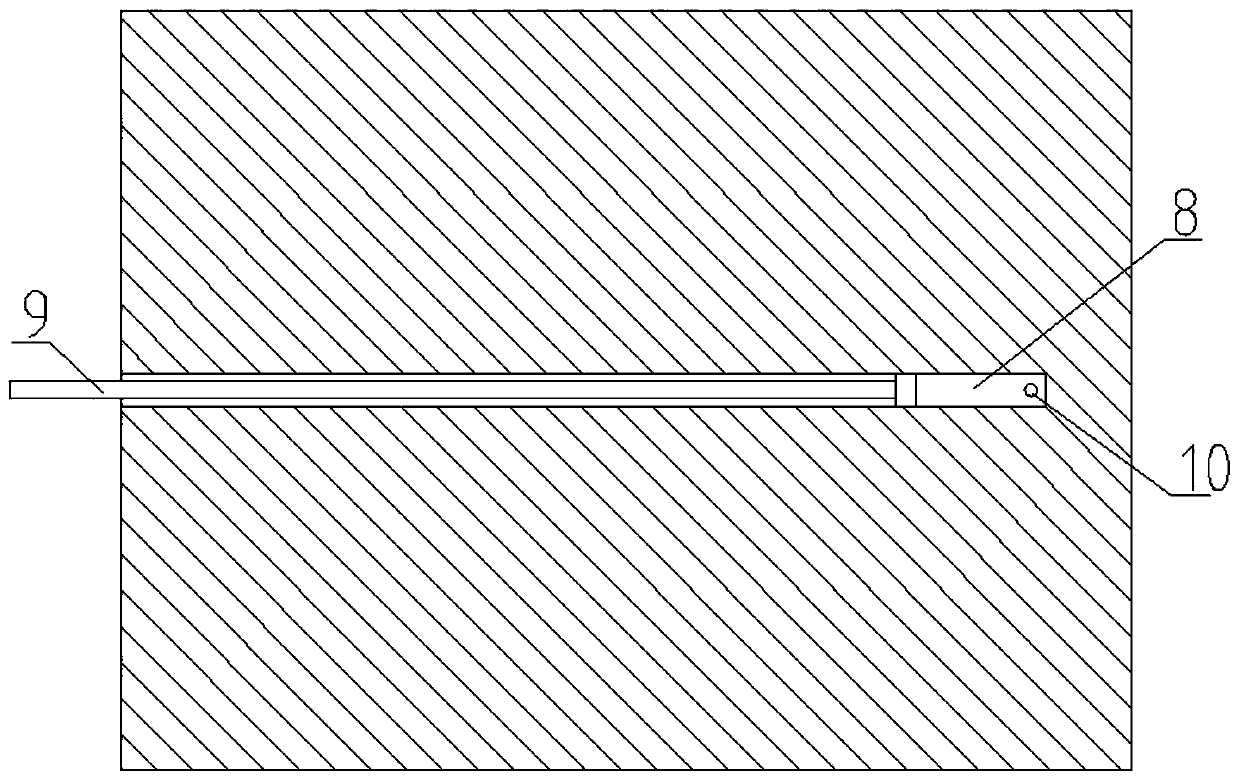

[0031] Such as figure 2 , image 3 , Figure 4 as shown, figure 2 It is a front view of the structure of the adsorption part of the screen; image 3 is a structural view of the communicating hole; Figure 4 is the structural view of the adsorption channel. A linear groove 6 is also arranged between the paired second adsorption holes 5, and the linear groove 6 communicates with the paired two second adsorption holes 5, corresponding to each of the linear grooves 6, and the screen absorbs Each part 3 is provided with a vacuum hole 7, the vacuum hole 7 is perpendicular to the end face of the screen adsorption part 3 where the second adsorption hole 5 is arranged, and the screen adsorption part 3 is also provided with a flexible The communication hole 8 extending in the length direction on the screen transfer carrying platform, the communication hole 8 is set as a linear hole, the communication hole 8 communicates with each of the linear grooves 6 through the vacuum hole 7,...

Embodiment 3

[0036]Preferably, the sealing member can be set as a rubber plug, and the inner wall of the communication hole 8 is smooth, so that the sealing member can move freely in the communication hole 8, and realize that the sealing member can move freely in the communication hole 8. The sealing effect of the communication hole 8 ensures the sealing of the entire adsorption channel. At the same time, the sealing rod 9 can be provided with external threads, and the sealing rod 9 is provided with a limit block that is threadedly connected with the sealing rod 9. When the sealing rod 9 is moved to a suitable position, it can be screwed The limit block makes the limit block lean against the position of the open port, thereby ensuring the position of the sealing rod 9 in the communication hole 8, and avoiding the sealing rod 9 when the suction channel is under negative pressure. The rod 9 moves due to the pressure difference.

[0037] In another embodiment, different from the above settin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com