Working method of pipe branching conveying mechanism

一种传送机构、工作方法的技术,应用在输送机、输送机物件、运输和包装等方向,能够解决工人劳动强度大、影响管件分路传送、管件分路传送效率低等问题,达到提高传送自动化程度、结构设计合理的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to further describe the present invention, a specific implementation of a branching transmission mechanism for pipe fittings will be further described below in conjunction with the accompanying drawings. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

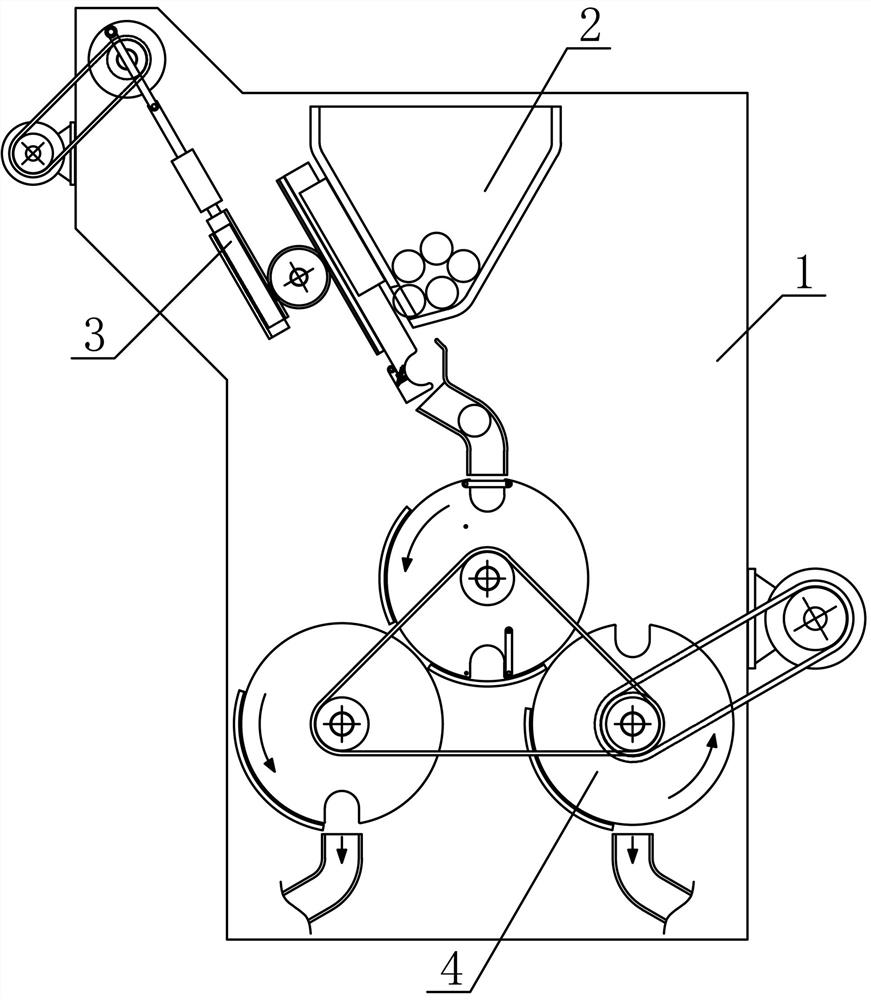

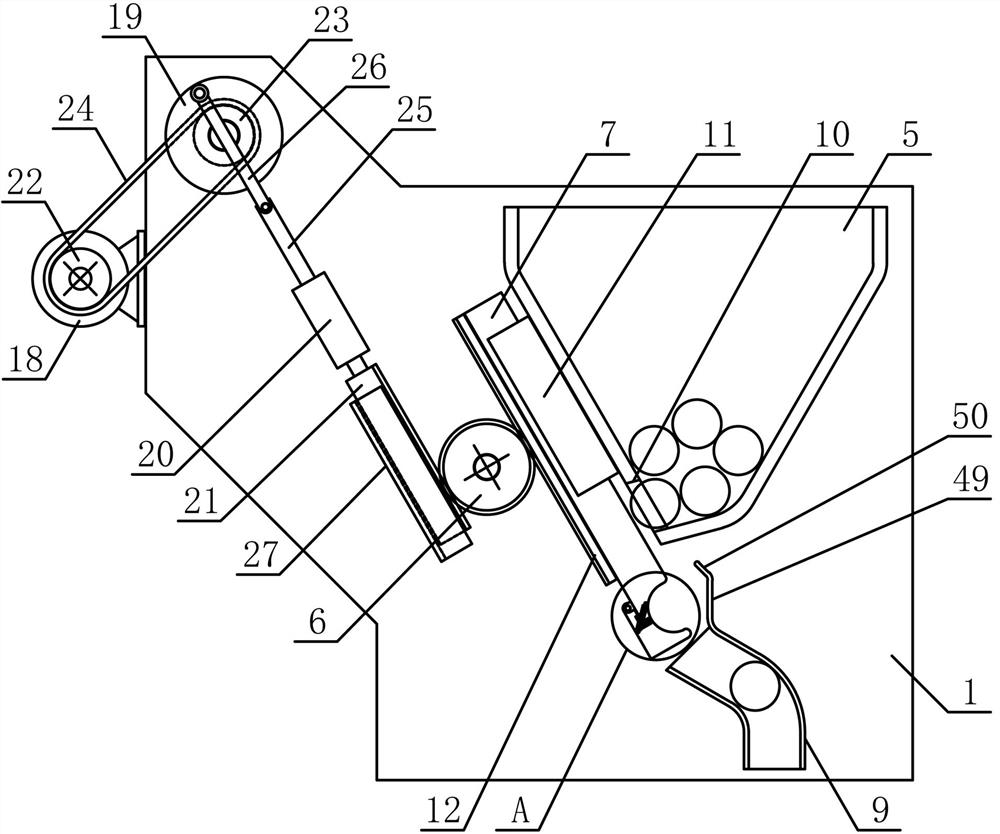

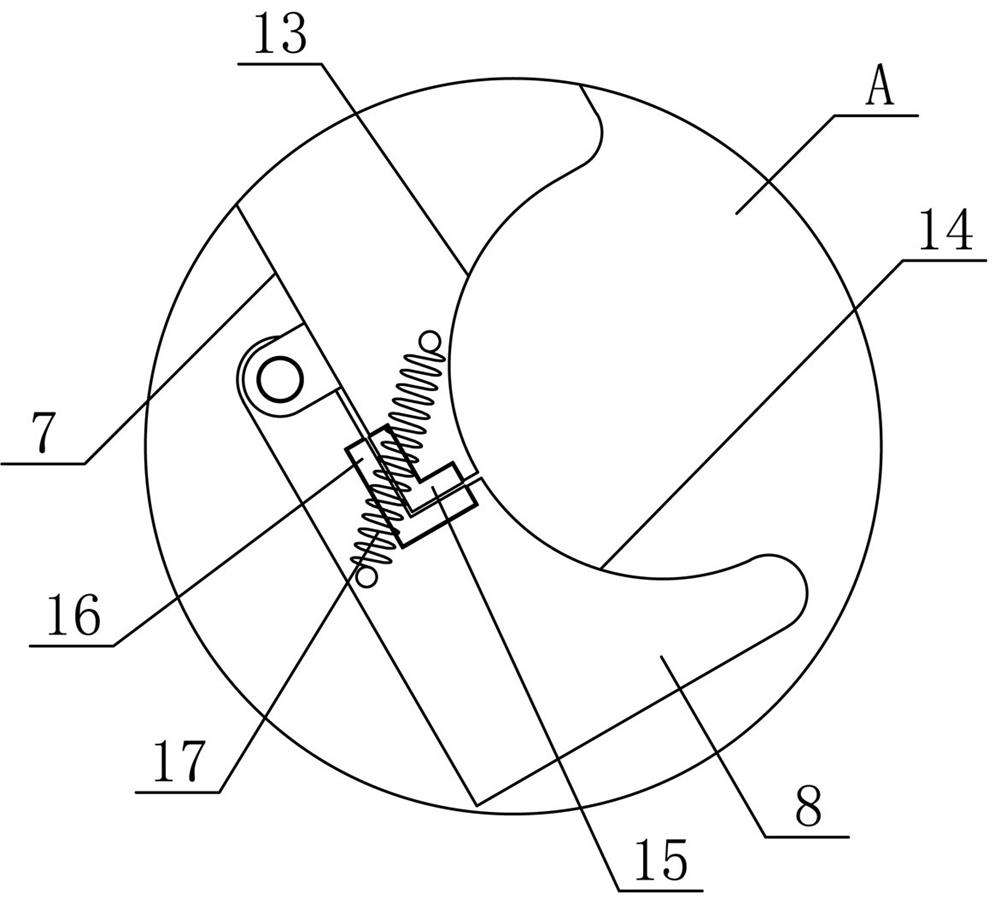

[0014] Such as figure 1 As shown, a pipe branching transmission mechanism of the present invention includes a pipe transfer bracket 1, a catheter mechanism 2, a driving mechanism 3 and a branching mechanism 4, and the catheter mechanism 2 and the branching mechanism 4 are fixed in sequence along the vertical direction from top to bottom It is arranged on the side of the pipe transmission support 1 , and the driving mechanism 3 is obliquely and fixedly arranged on the pipe transmission support 1 on the side of the catheter mechanism 2 . Such as figure 2 As shown, the conduit mechanism 2 of the present invention includes a stora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com