Equipment special for splicing plastic hoses

A plastic hose and equipment technology, which is applied in the field of splicing equipment between plastic hoses, can solve problems such as splicing deviation, difficulty in clamping and fixing, and inability to splice hoses, so as to improve efficiency, facilitate adsorption and fixation, and reduce difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

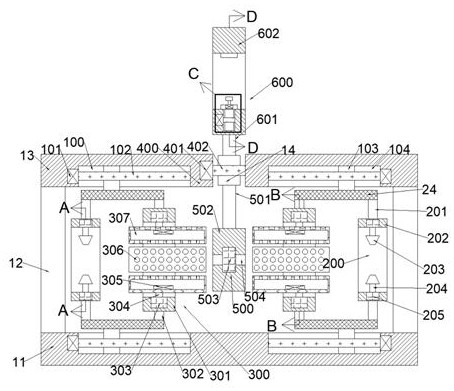

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0029] Such as Figure 1-8 As shown, a device dedicated to splicing plastic hoses includes a base plate 11, and four support rods 12 are arranged in an array on the end of the base plate 11 away from the ground, and the support rods 12 are far away from the base plate 11. A mounting plate 13 is fixedly connected to one end wall, and a moving device 100 is symmetrically arranged on the side end wall where the bottom plate 11 and the mounting plate 13 are close to each other, and the moving device 100 is used for moving the fixed plate 24;

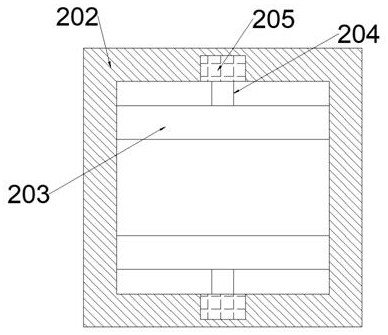

[0030] A clamping and closing device 200 is arranged between the fixing plates 24, and the clamping and closing device 200 is used for clamping and closing the hose;

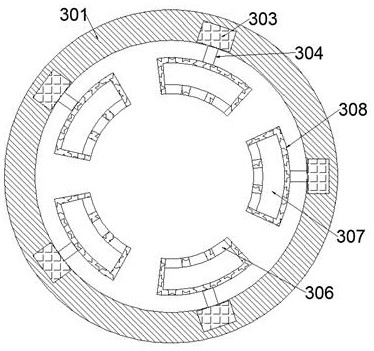

[0031] An adsorption fixing device 300 is arranged between the fixing plates 24, and the adsorp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com