Self-adaptive floating breathing device and breathing oil tank with same

A breathing device, self-adaptive technology, applied in the direction of valve device, oil supply tank device, engine components, etc., can solve the problem of oil leaking from the fuel tank respirator, and achieve the effect of ensuring the sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

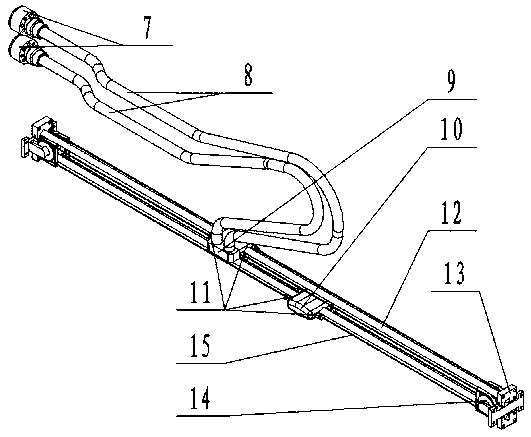

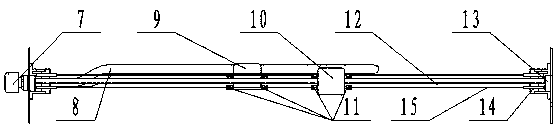

[0037] This embodiment discloses an adaptive floating breathing device, such as Figure 1-9 As shown, it includes a slidable floating breathing block 9 arranged in the fuel tank, and the floating breathing block 9 communicates with the outside through the provided breathing hose 8; when the fuel tank is tilted, the floating breathing block 9 slides to a high point to avoid Contact with oil.

[0038] A guide rod 12 is provided inside the oil tank, and the floating breathing block 9 is arranged on the guiding rod 12 and slides along the guiding rod 12; Reverse sliding power traction block 10, when the fuel tank is tilted, the power traction block 10 slides towards the low point under the action of gravity and guides the floating breathing block 9 to slide towards the high point. The fuel tank is provided with at least two guide rods 12 parallel to each other, and the floating breathing block 9 and the power traction block 10 are respectively arranged on different guide rods 12; ...

Embodiment 2

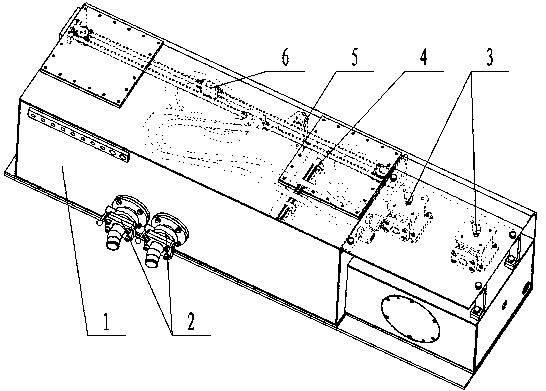

[0045] This embodiment discloses as figure 1 As shown, a breathing oil tank includes an oil tank body 1, an oil suction filter 2, an oil return filter 3, a magnetic filter 4, an oil level oil temperature gauge 5, and an adaptive floating breathing system 6. The position behind the lower right side of the oil tank body 1 is the oil suction filter 2, the position near the top of the oil tank body 1 is the oil return filter 3, the middle position in the oil tank body 1 is the magnetic filter 4, the oil tank body 1. The middle part on the left side is the oil level oil temperature gauge 5, and the top position inside the fuel tank body 1 is the self-adaptive floating breathing system 6;

[0046] Such as Figure 5 As shown, the fuel tank body 1 has the basic functions of a fuel tank and is equipped with a floating breathing system installation function. The oil drain port 16 is located at the upper right rear side of the oil tank body 1, the oil suction port 17 is located at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com