Selenium drum pin pressing-in tool assembly

A pin and tooling technology, which is applied in the field of printer auxiliary tooling components, can solve the problems such as the difficulty in installing the pins of the toner cartridge, and achieve the effect of improving work efficiency and reducing the time required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

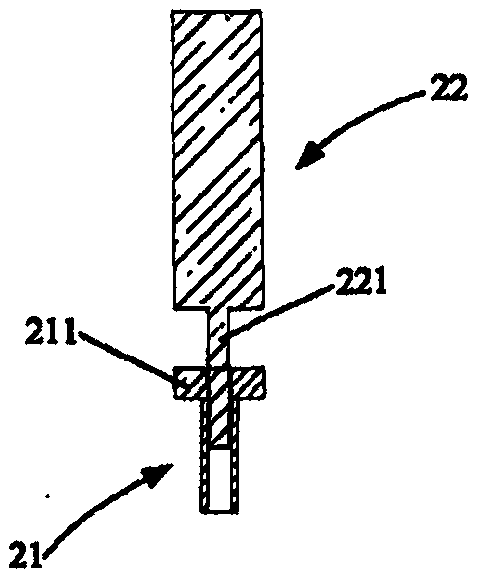

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0012] see image 3 , a toner cartridge pin pressing tooling assembly, comprising: a pin positioning member 21 and a pin pressing rod 22, the pin positioning member 21 is a hollow cylinder on which is provided with a card protrusion 211 for easy disassembly, and the top of the pin pressing rod 22 A cylindrical protrusion 221 is provided, and the cylindrical protrusion 221 is inserted into the pin positioning member 21 .

[0013] In this example, the outer diameter of the pin positioning member 21 is the same as the diameter of the insertion hole 14 , and its inner diameter corresponds to the diameter of the pin 13 . The diameter of the cylindrical protrusion 221 of the pin pressing rod 22 is the same as the inner diameter of the pin 13 .

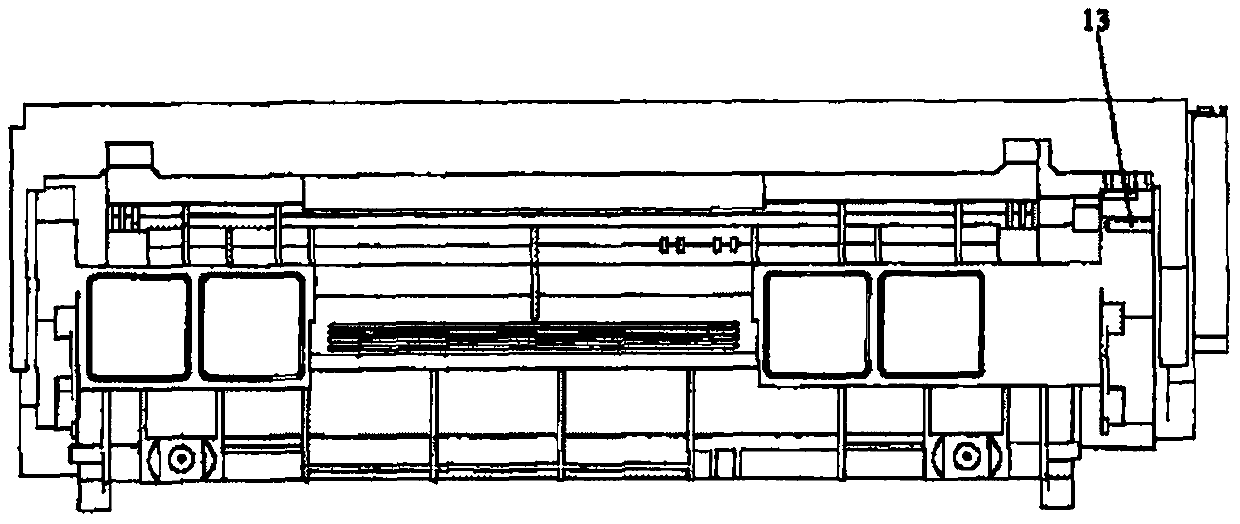

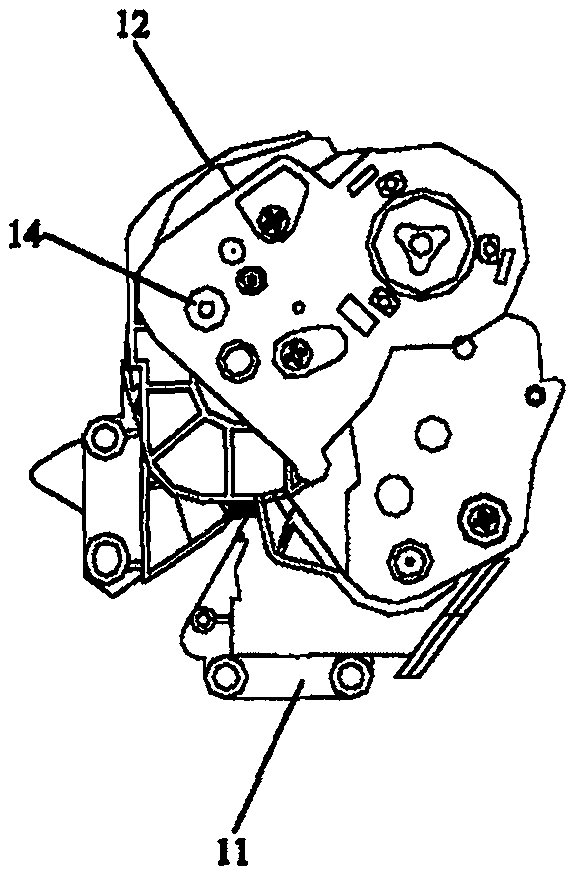

[0014] see Figure 4 , which is a working diagram of the toner cartridge pin press-in tooling assembly of the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com