A self-cleaning oil fume gas detection device

A technology of gas detection and gas detector, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of air pollution, inability to measure at any time, inconvenient use, etc., and achieve the effect of novel design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

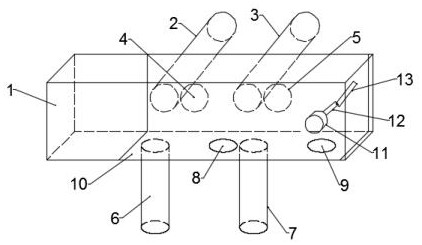

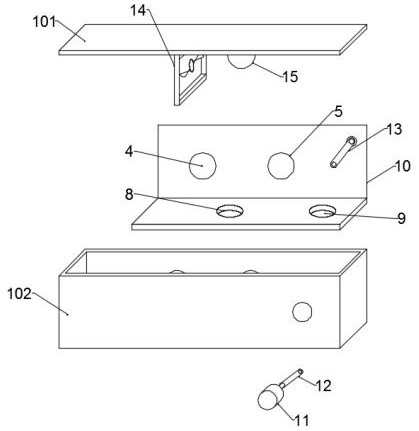

[0022] In the embodiment of the present invention, a self-cleaning soot gas detection device includes a main box body 1; the rear end of the main box body 1 is communicated with a first air duct that extends into the exhaust channel and is used to collect gas that needs to be analyzed 2 and the second air duct 3, the lower end of the main box body 1 communicates with the third air duct 6 and the fourth air duct 7 for gas discharge, preferably, the first air duct 2 and the third air duct 6 On the same treatment surface, the second air duct 3 and the fourth air duct 7 are on the same vertical plane, and the inner side of the main box body 1 is slidably installed with a sliding plate 10 driven by a drive assembly, and the sliding plate 10 is L-shaped. Type setting, its upright end is provided with first through hole 4 and second through hole 5, preferably, the distance between described first through hole 4 and second through hole 5 is the same as the first air guide tube 2 and th...

Embodiment 2

[0027] Specifically, the second embodiment is a further description of the structure of the driving mechanism. The driving mechanism includes a motor 11 installed on the outer end of the main box body 1, a connecting rod 12 fixed on the output shaft of the motor 11, and a connecting rod 12 mounted on the sliding plate 10 for rotation. The push rod 13, the end of the connecting rod 12 away from the output shaft of the motor 11 is rotationally connected with the end of the push rod 13 away from the joint of the sliding plate 10, and the sliding plate is driven by the action of the connecting rod 12 and the pushing rod 13 when the motor 11 rotates 10 moves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com