Ejector for fire-fighting equipment and fire-fighting equipment

A fire-fighting equipment and ejector technology, which is applied in the field of ejectors for fire-fighting equipment and fire-fighting equipment, can solve the problems such as laboriousness of firefighters to drag water pipes, inability to meet the fire-extinguishing range, low water pressure, etc., saving time and effort in the operation process , The operation process is fast and the effect of reducing the caliber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

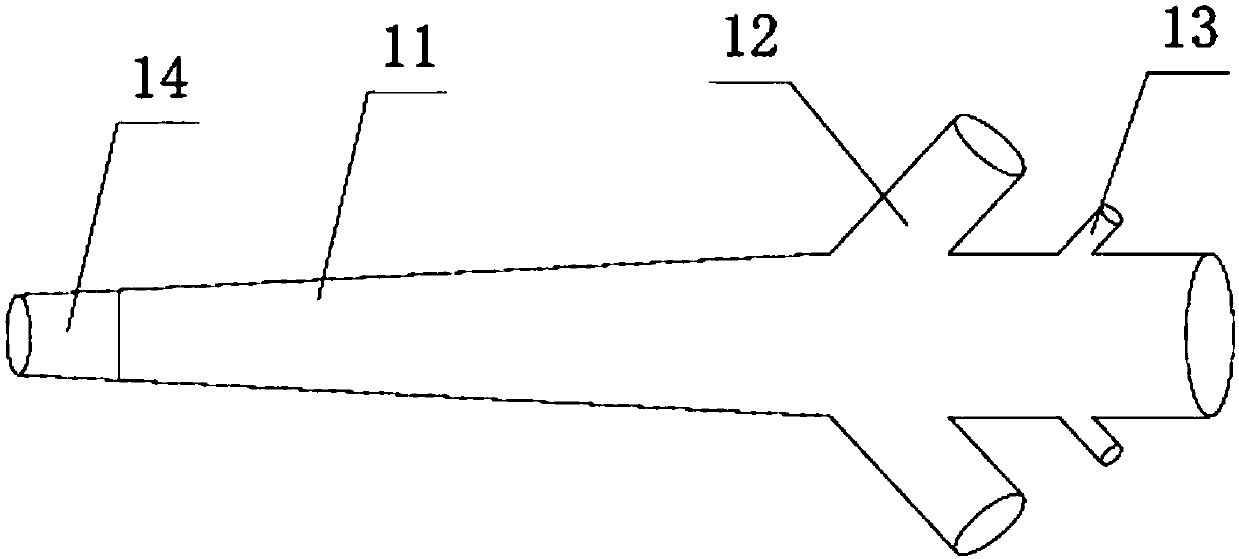

[0014] See figure 1 , a fire-fighting equipment injector, including a main water pipe 11, two auxiliary water pipes 12 and two injection booster pipes 13 communicated with the side walls of the main water pipe 11; the jet booster pipe 13 is connected to the high-pressure gas delivery pipe , used to transport high-pressure gas; the main water pipe 11 is a variable-diameter pipe, and the pipe diameter gradually decreases from the water inlet end to the water outlet end; Tight groove, and the main water delivery pipe is provided with the outer wall of the compression groove and is screwed and connected with a water output adjusting nut 14.

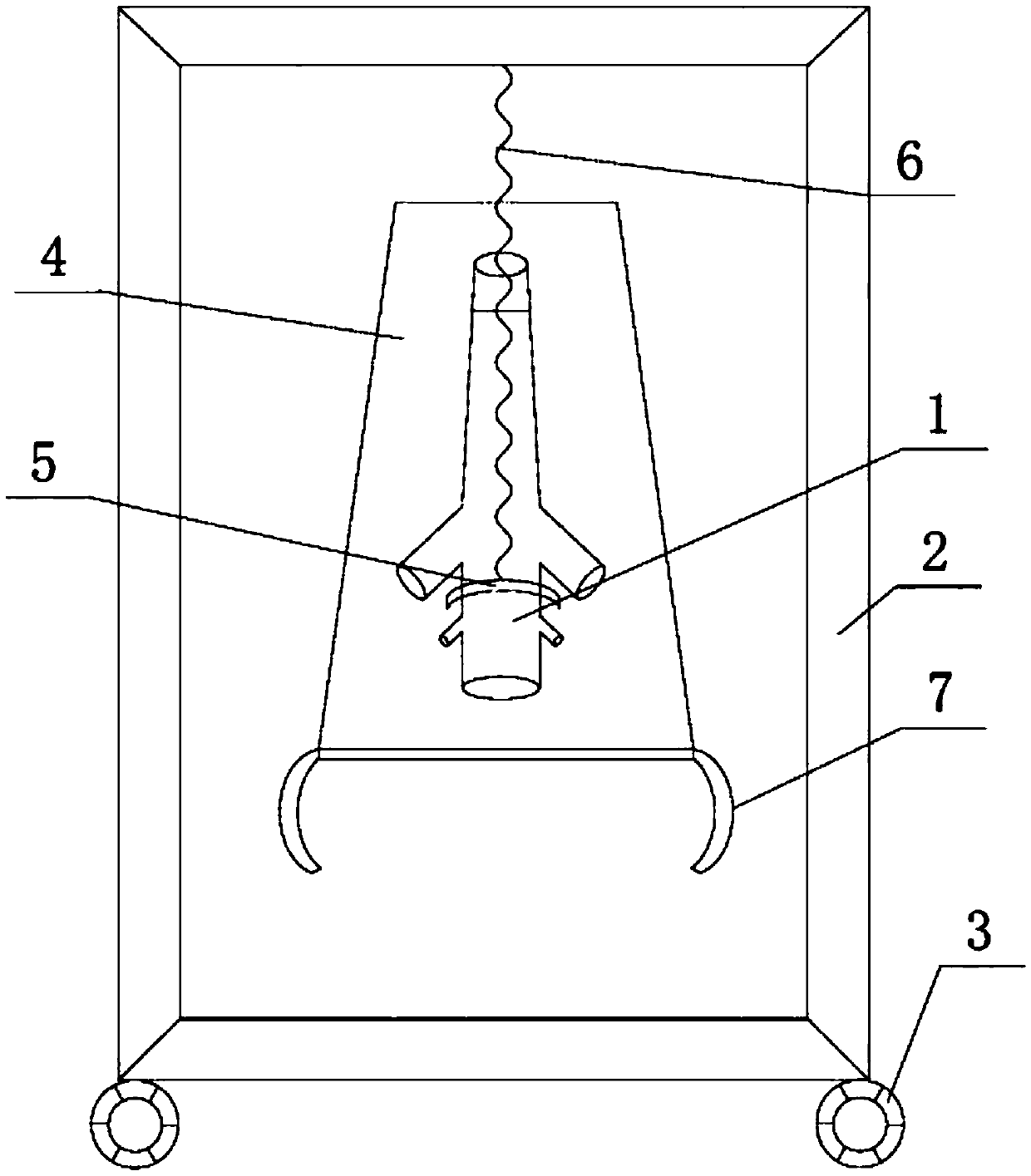

[0015] See figure 2 , a kind of fire-fighting equipment, including a box-type operation room 2 and an injector 1 arranged in the box-type operation room 2, the bottom end of the box-type operation room 2 is provided with a roller 3; the box-type operation room 2 is provided with a sprayer The positioning plate 4, the injector 1 is fixed on...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap