Intelligent lithium battery diaphragm tension control device and control method

A lithium battery separator and tension control technology, which is used in transportation and packaging, coiling strips, and thin material processing. Quality, increased yield, improved effect of fast response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

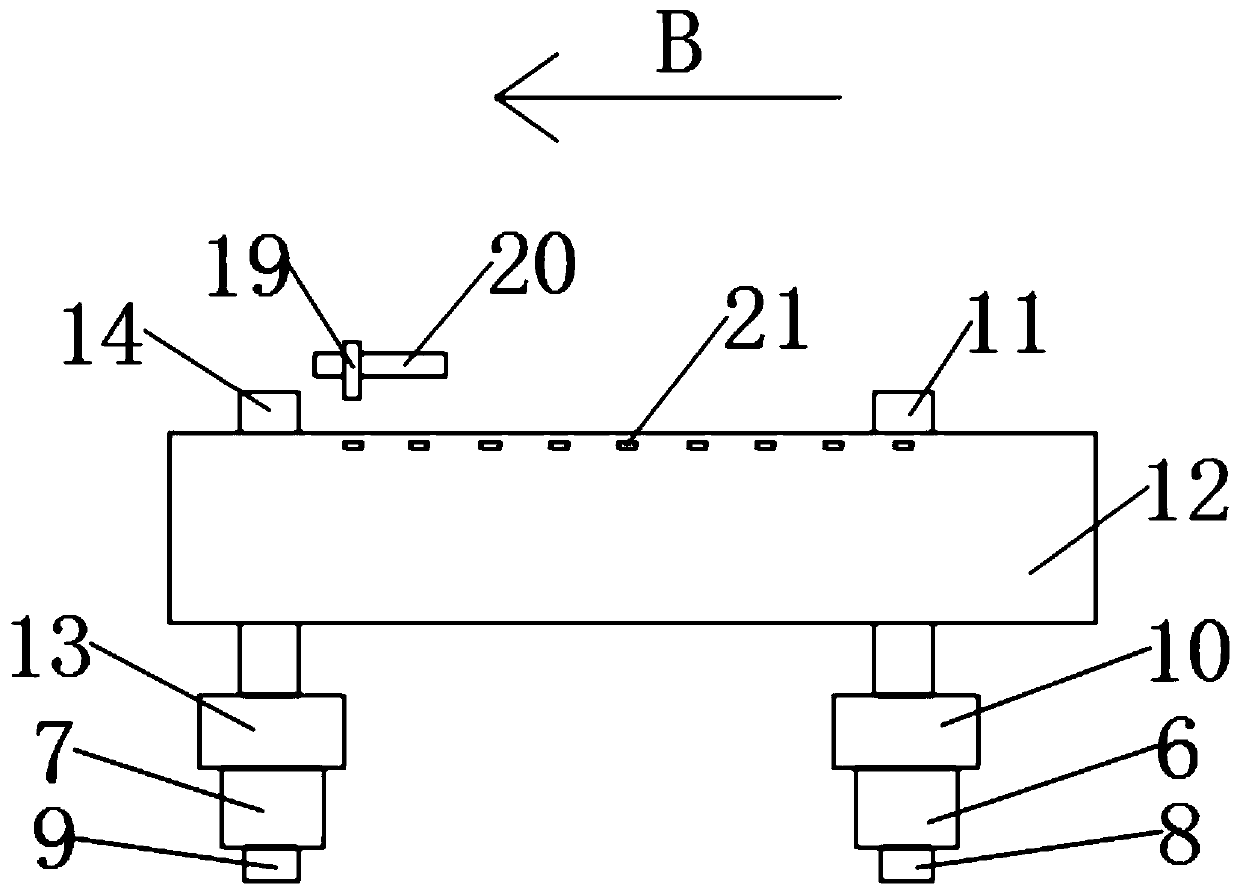

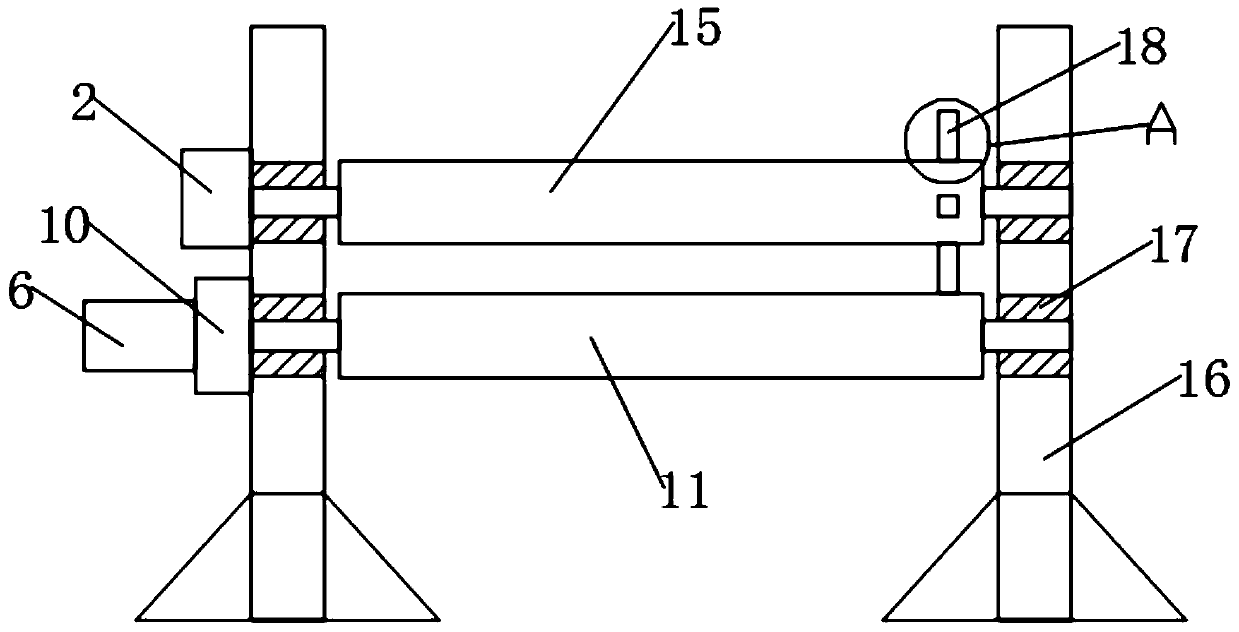

[0030] Such as Figure 1-Figure 4 As shown, an intelligent lithium battery diaphragm tension control device includes a PLC controller 1, a drive motor 2, a first servo driver 3, a second servo driver 4 and a display 5, and the first servo driver 3 and the second servo driver 4 are respectively Connected with the first servo motor 6 and the second servo motor 7, the first servo motor 6 and the second servo motor 7 are respectively provided with a first incremental encoder 8 and a second incremental encoder 9, the first servo The output end of the motor 6 is connected to the first diaphragm transmission roller 11 through the first gearbox 10, the output end of the second servo motor 7 is connected to the second diaphragm transmission roller 14 through the second gearbox 13, and the first diaphragm transmission roller 11 is located at The input end of the lithium battery diaphragm 12, the second diaphragm transmission roller 14 is located at the output end of the lithium battery ...

Embodiment 2

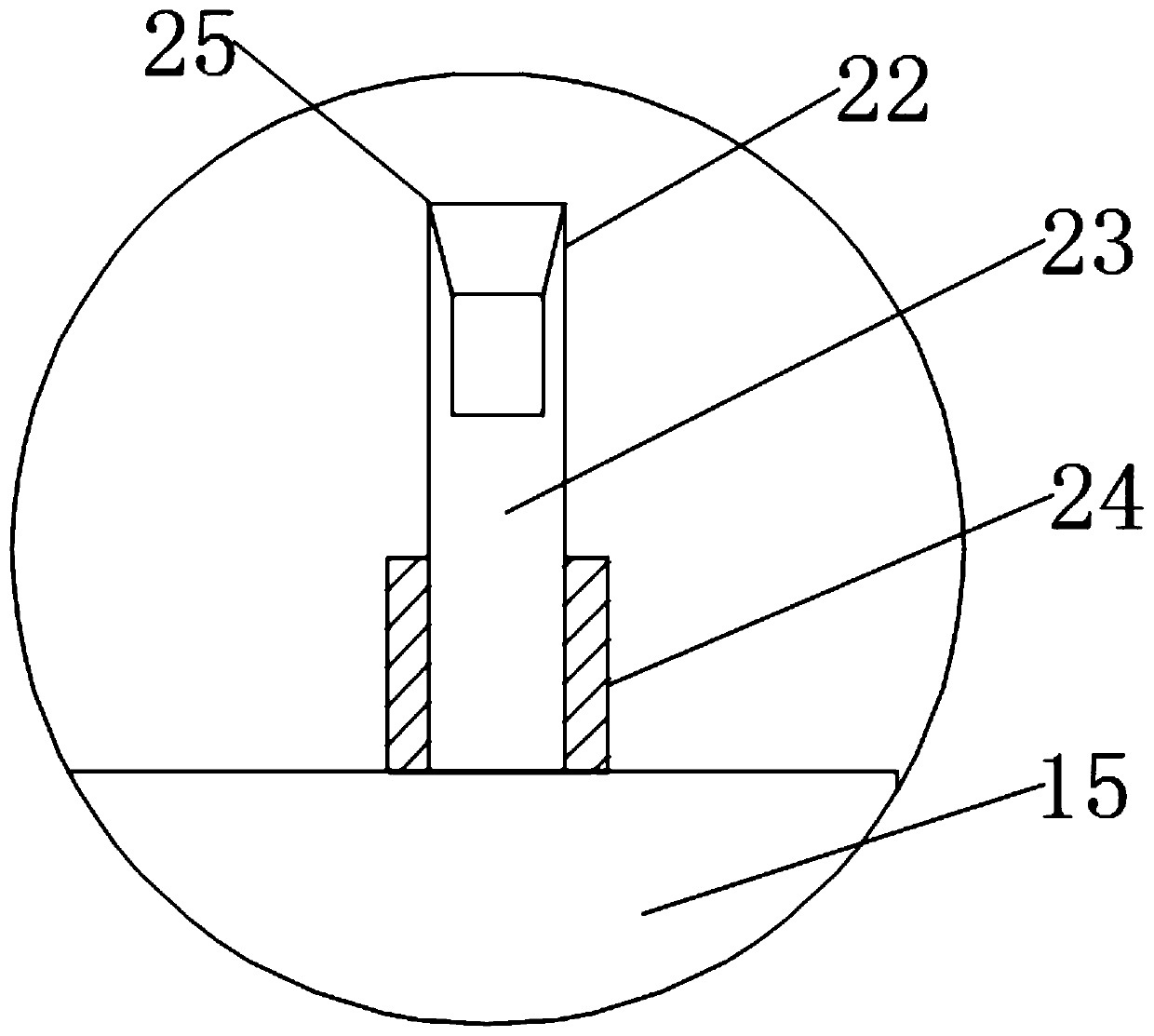

[0034] Such as image 3 As shown, on the basis of Embodiment 1 in this embodiment, the punching knife 18 includes a cutter head 22 and a blade body 23, and the right end of the marking roller 15 is evenly distributed with two mounting seats 24 along the circumferential direction, and the blade body 23 is threaded with the mounting seat 24. The connection is convenient for disassembly and replacement. The top end of the cutter head 22 is recessed with an inner cone surface, and the end of the inner cone surface forms a blade 25 .

Embodiment 3

[0036] A method for intelligently controlling the tension of a lithium battery diaphragm, comprising the following steps:

[0037] S1. Set the initial rotation rate of the first diaphragm transmission roller 11 and the second diaphragm transmission roller 14 through the data input module of the display 5, then start the first servo motor 6 and the second servo motor 7 to drive the first diaphragm transmission roller 11 and The second diaphragm transfer roller 14 works to transfer the lithium battery diaphragm;

[0038] S2. The first incremental encoder 8 and the second incremental encoder 9 respectively monitor the rotation speed and position information of the first diaphragm transmission roller 11 and the second diaphragm transmission roller 14 in real time;

[0039] S3. The PLC controller 1 receives the information from the first incremental encoder 8 and the second incremental encoder 9, and based on the rotation rate and position information of the first diaphragm transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com