Steel ladle bottom argon blowing refining method

A bottom-blowing argon and ladle technology, applied in casting melt containers, manufacturing tools, metal processing equipment, etc., can solve the problem of large gas flow rate of slit-type breathable bricks, affecting the effect of argon blowing, stirring and mixing, and affecting the removal of argon bubbles. It can improve the removal rate of inclusions, improve the mixing effect, and shorten the refining time of argon blowing in the whole process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

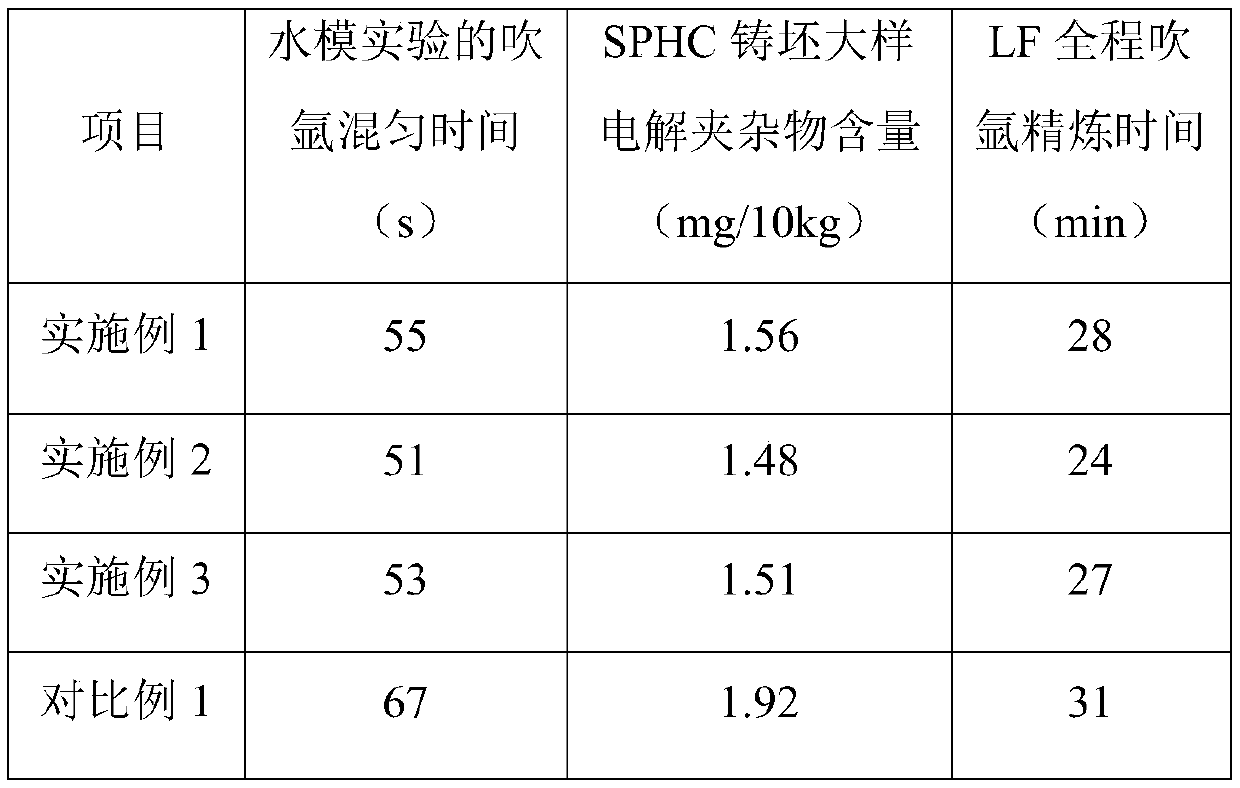

Embodiment 1

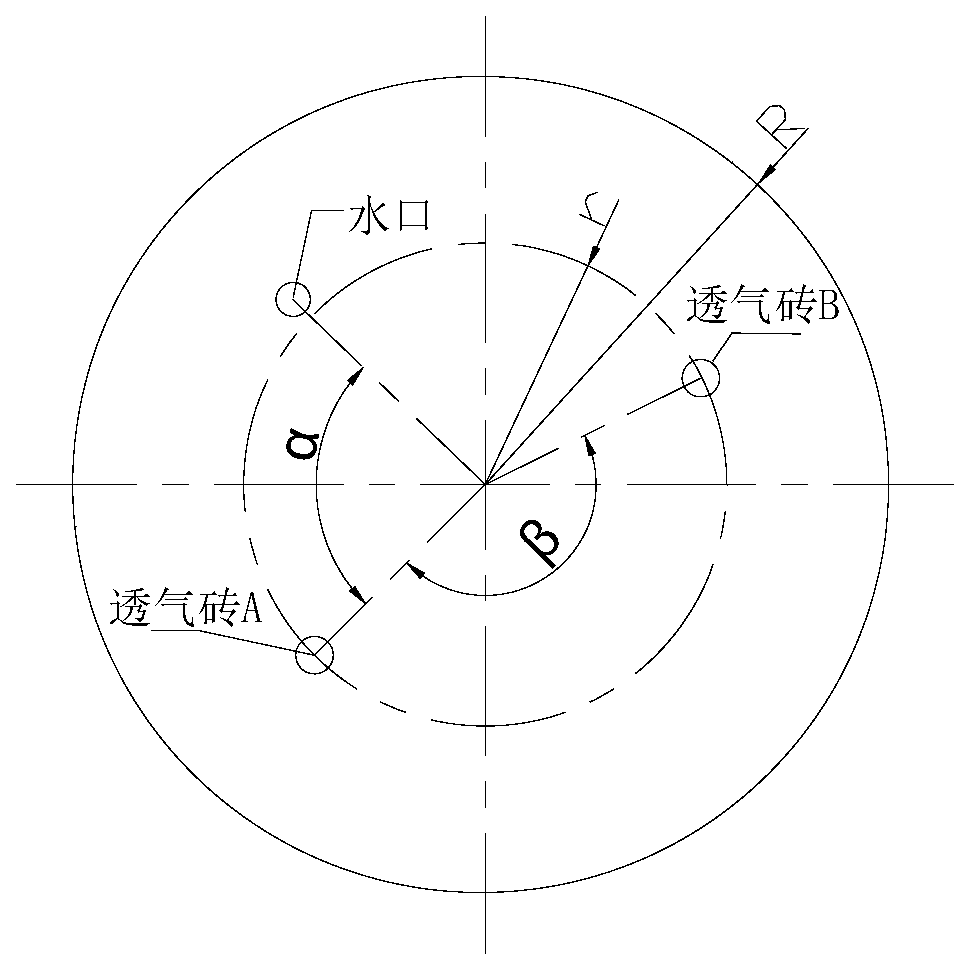

[0019] In this invention, a slit type air-permeable brick A and a diffuse air-permeable brick B are arranged on an arc with the center of the ladle bottom as the center and a radius of r. The argon blowing control is divided into two stages:

[0020] 1) During the argon blowing, stirring and mixing stage, the argon blowing flow control requirements: the argon blowing flow of the slit type venting brick A is 800NL / min, and the argon blowing flow of the dispersing venting brick B is 400NL / min;

[0021] 2) Inclusion removal stage by soft blowing: argon blowing flow control requirements: the argon blowing flow of slit type venting brick A is 200NL / min, and the argon blowing flow of dispersing venting brick B is 200NL / min.

[0022] The arc radius r=0.66R, where R is the radius of the bottom circle of the ladle.

[0023] The included angle α between the slit type ventilation brick A and the arc radius of the nozzle is 90°, and the included angle β between the slit type ventilation brick A an...

Embodiment 2

[0026] The ladle bottom argon blowing refining method as described in Example 1, the difference is:

[0027] In this invention, a slit type air-permeable brick A and a diffuse air-permeable brick B are arranged on an arc with the center of the ladle bottom as the center and a radius of r. The argon blowing control is divided into two stages:

[0028] 1) During the argon blowing, stirring and mixing stage, the argon blowing flow control requirements: the argon blowing flow of the slit type venting brick A is 1200NL / min, and the argon blowing flow of the dispersing venting brick B is 100NL / min;

[0029] 2) Inclusion removal stage by soft blowing: argon blowing flow control requirements: the argon blowing flow of slit type venting brick A is 100NL / min, and the argon blowing flow of dispersing venting brick B is 100NL / min.

[0030] The arc radius r=0.60R, where R is the radius of the bottom circle of the ladle.

[0031] The included angle α between the slit type ventilation brick A and the ...

Embodiment 3

[0033] The ladle bottom argon blowing refining method as described in Example 1, the differences are:

[0034] In this invention, a slit type air-permeable brick A and a diffuse air-permeable brick B are arranged on an arc with the center of the ladle bottom as the center and a radius of r. The argon blowing control is divided into two stages:

[0035] 1) During the argon blowing, stirring and mixing stage, the argon blowing flow control requirements: the argon blowing flow of the slit type venting brick A is 1000NL / min, and the argon blowing flow of the dispersing venting brick B is 200NL / min;

[0036] 2) Inclusion removal stage by soft blowing: argon blowing flow control requirements: the argon blowing flow of slit type venting brick A is 150NL / min, and the argon blowing flow of dispersing venting brick B is 150NL / min.

[0037] The arc radius r=0.64R, where R is the radius of the bottom circle of the ladle.

[0038] The included angle α between the slit type ventilation brick A and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com