A liquid nitrogen freezer and processing method for vertical compartmental freezing

A technology of freezer and liquid nitrogen, which is applied in infrastructure engineering, soil protection, construction, etc., can solve the problems of poor uniformity of frozen walls, difficult control, and inability to accurately control the development of frozen soil, and achieve uniform freezing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

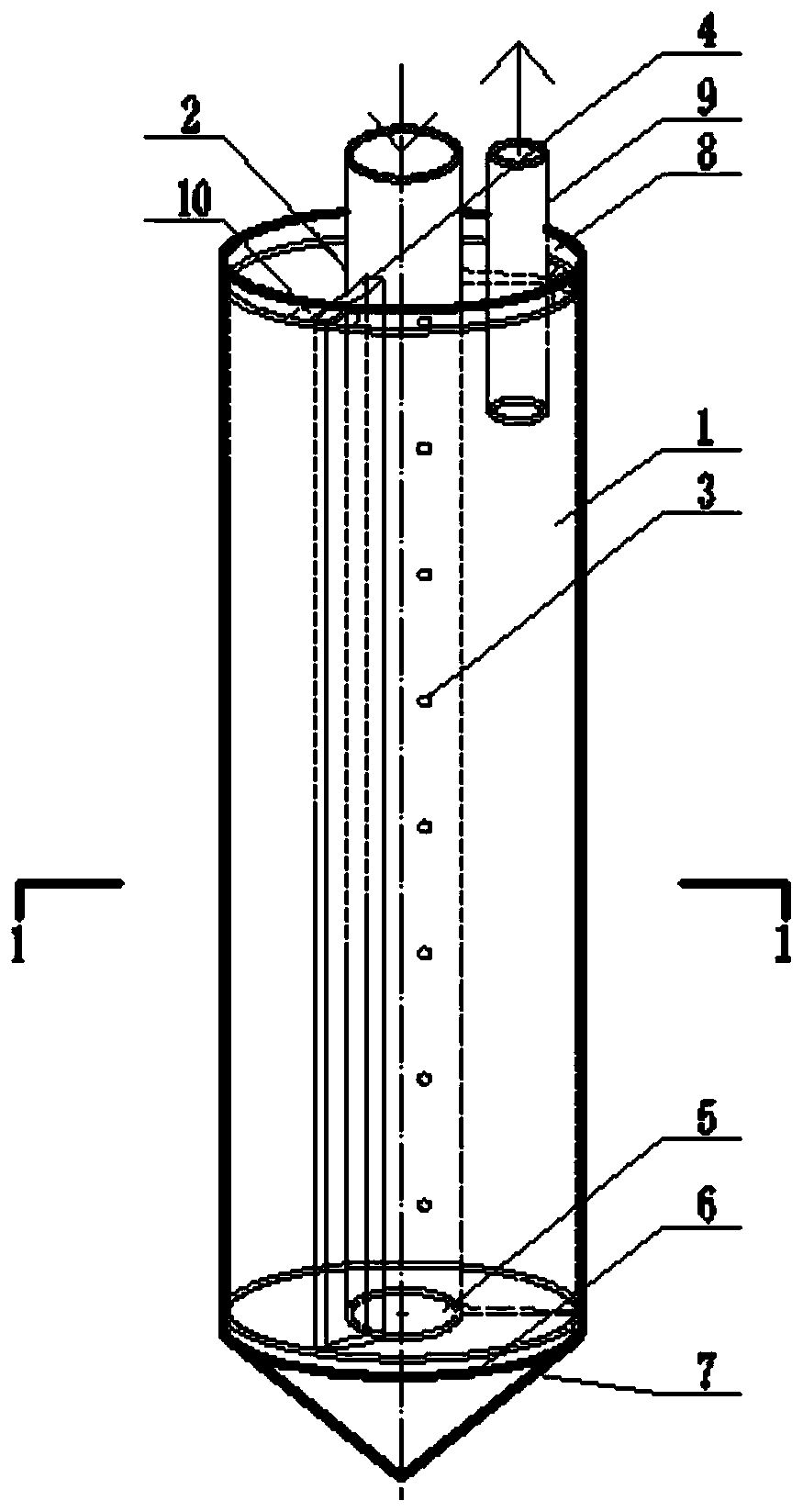

[0022] An embodiment of the present invention will be further described below in conjunction with accompanying drawing

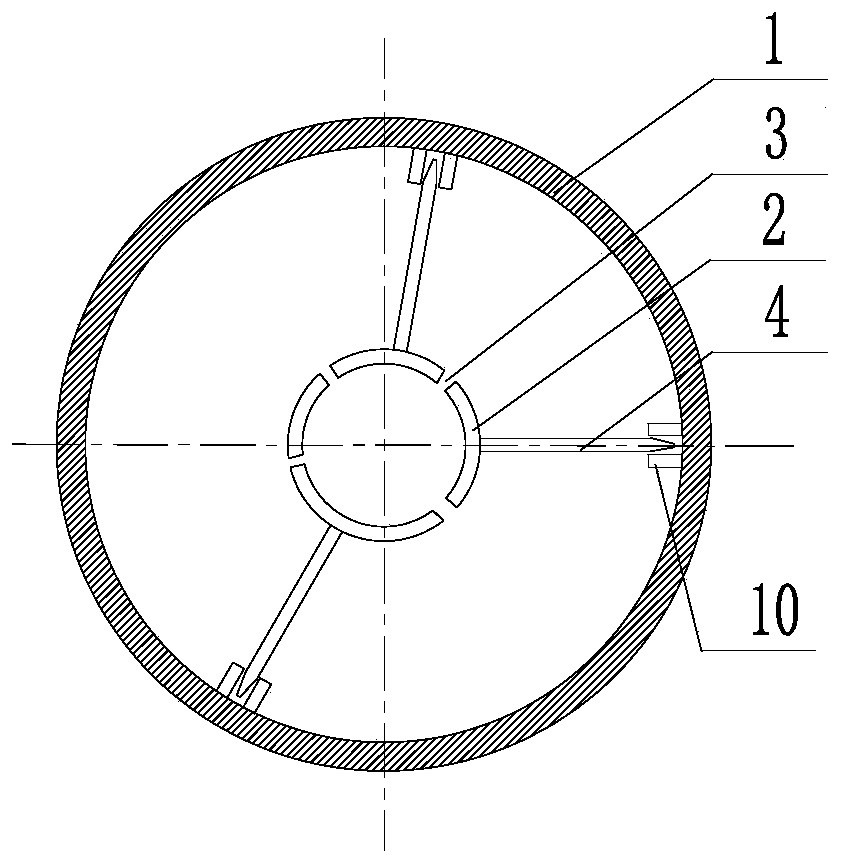

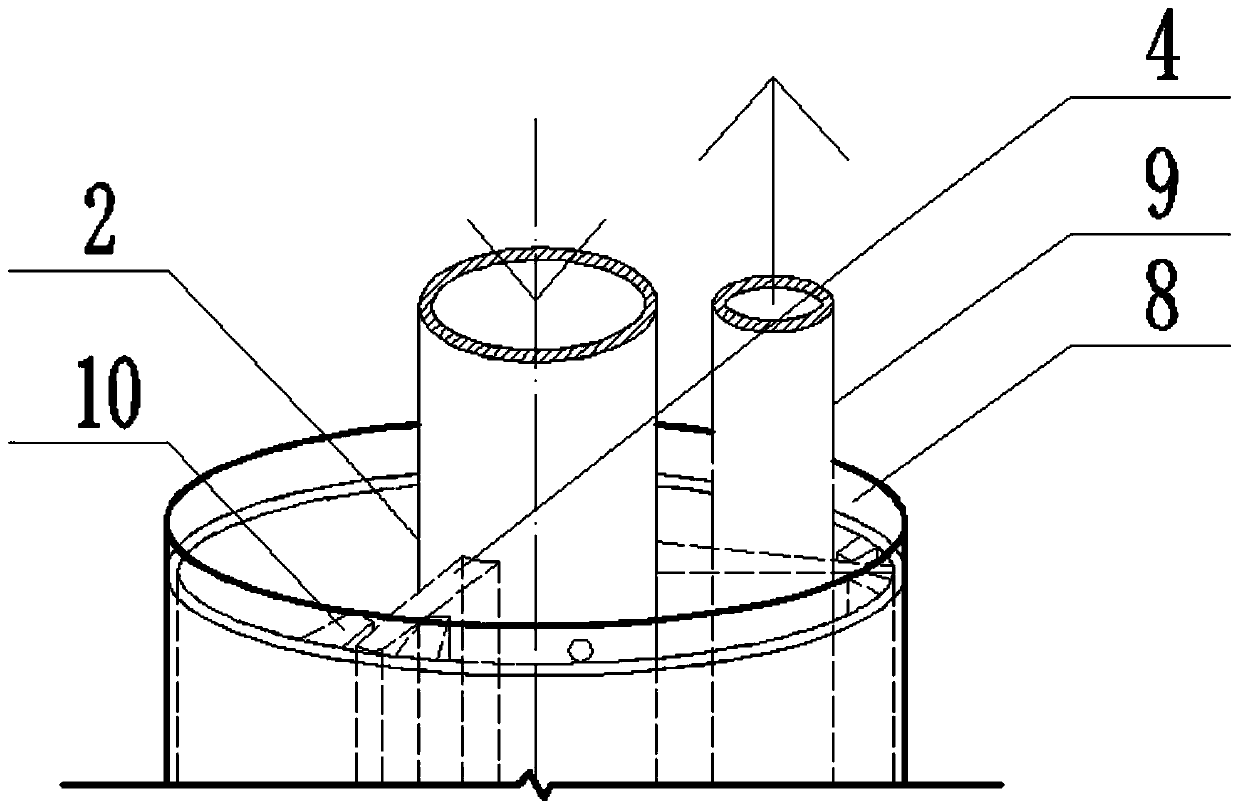

[0023] Such as figure 1 As shown, the liquid nitrogen freezer for freezing in vertical bins according to the present invention includes a freezing tube 1 with a columnar structure. The liquid supply pipe 2 of the freezing pipe 1 is provided with a plurality of spray holes 3 on the side wall of the liquid supply pipe 2, the bottom of the liquid supply pipe 2 is sealed and is provided with a plug 5, and one side of the liquid supply pipe 2 at the top of the freezing pipe 1 is provided with There is the air outlet pipe 9 connected with the frozen pipe 1 mile, such as figure 2 As shown, the inner wall of the freezing pipe 1 is axially provided with a freezing pipe inner chute 10 matching the number and position of the rib plate 4, and vertical ribs are arranged between each freezing pipe inner chute 10 and the outer wall of the liquid supply pipe 2 The plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com