Building plate painting device

A technology for construction and boards, which is applied in spraying devices, spray booths, etc., can solve the problems of easily crushed board surfaces, etc., and achieve the effect of improving the convenience of movement, improving stability and facilitating transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

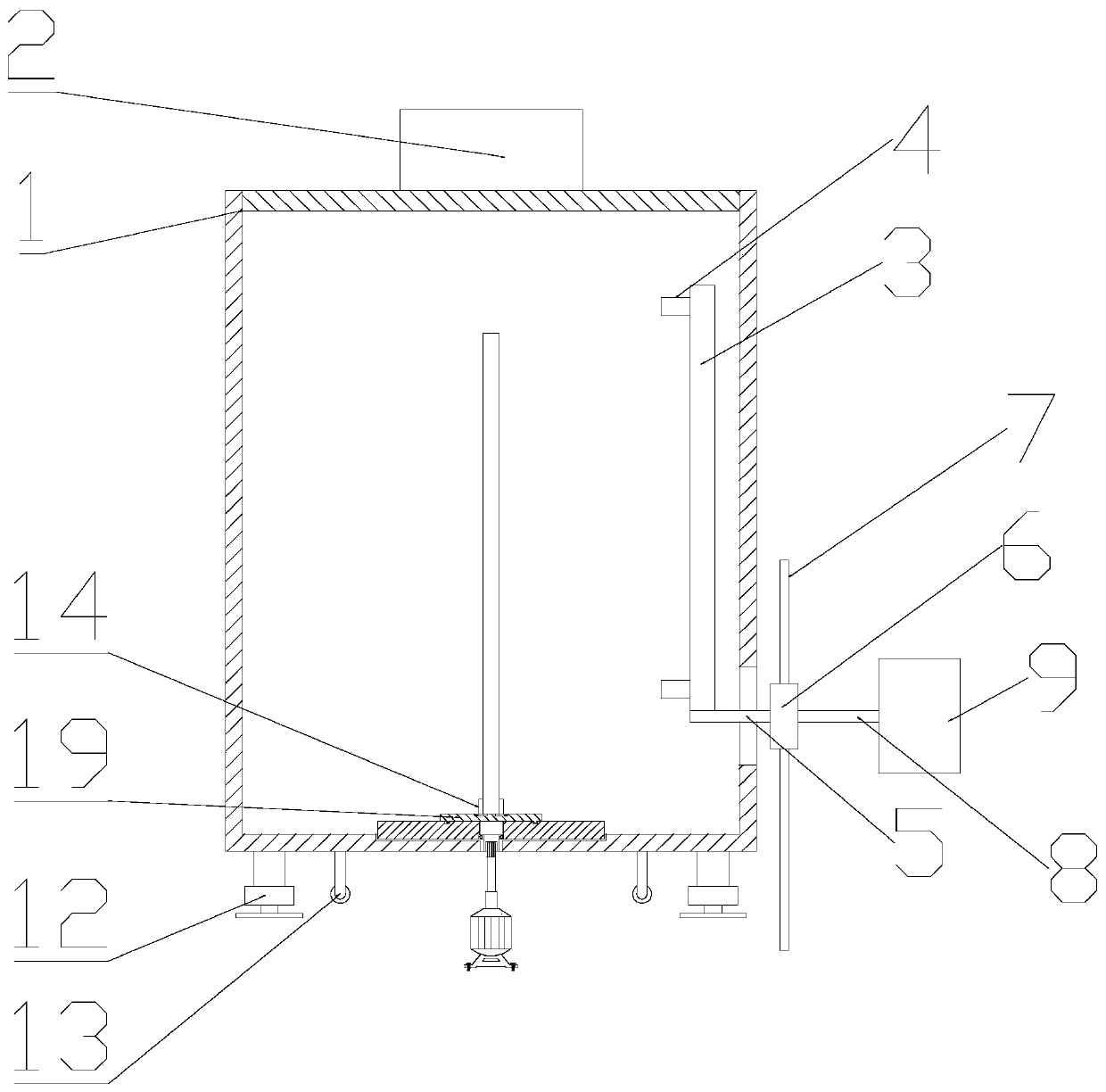

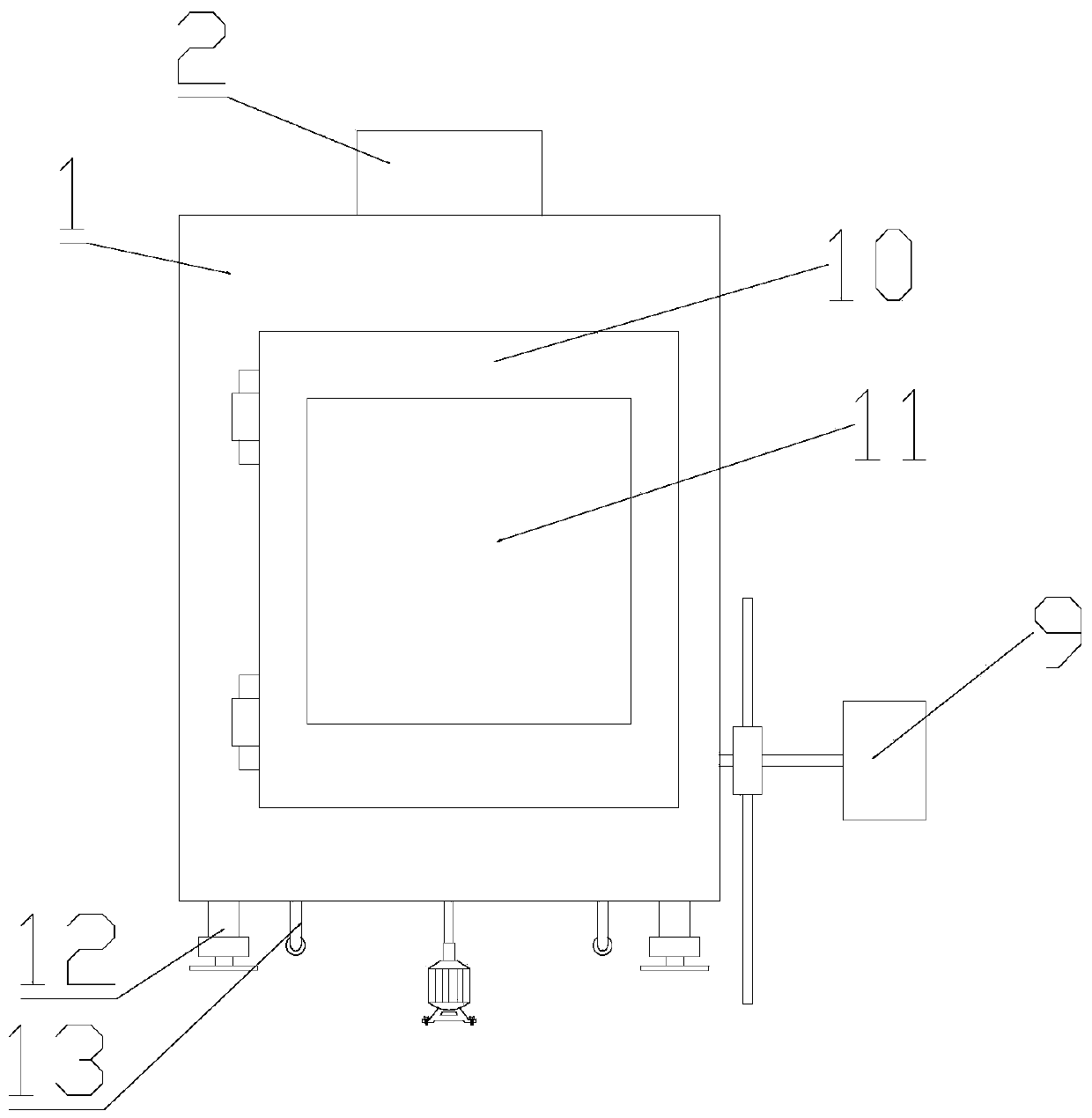

[0018] see figure 1 and figure 2 , a kind of plate paint spraying device for building, comprises paint spraying box 1, ventilating device 2, spray head installation frame 3, spray head 4 and spray head elevating bar 5, described spray paint box 1 is a cavity structure, and described paint spray box 1 upper end surface is provided with The ventilation device 2, the ventilation device 2 communicates with the paint spray box 1, the spray head mounting frame 3 is arranged on the right side of the inner cavity of the paint spray box 1, and the spray head mounting frame 3 is installed on the left end surface. The spray head 4, the bottom bolt of the spray head mounting frame 3 is fixed on the spray head lifting rod 5; the spray head lifting rod 5 extends out of the paint spray box 1 to the right and is welded and fixed with the lifting block 6, and the lifting block 6 is up and down Slidingly installed on the guide rail 7, the right end surface of the lifting block 6 is welded and...

Embodiment 2

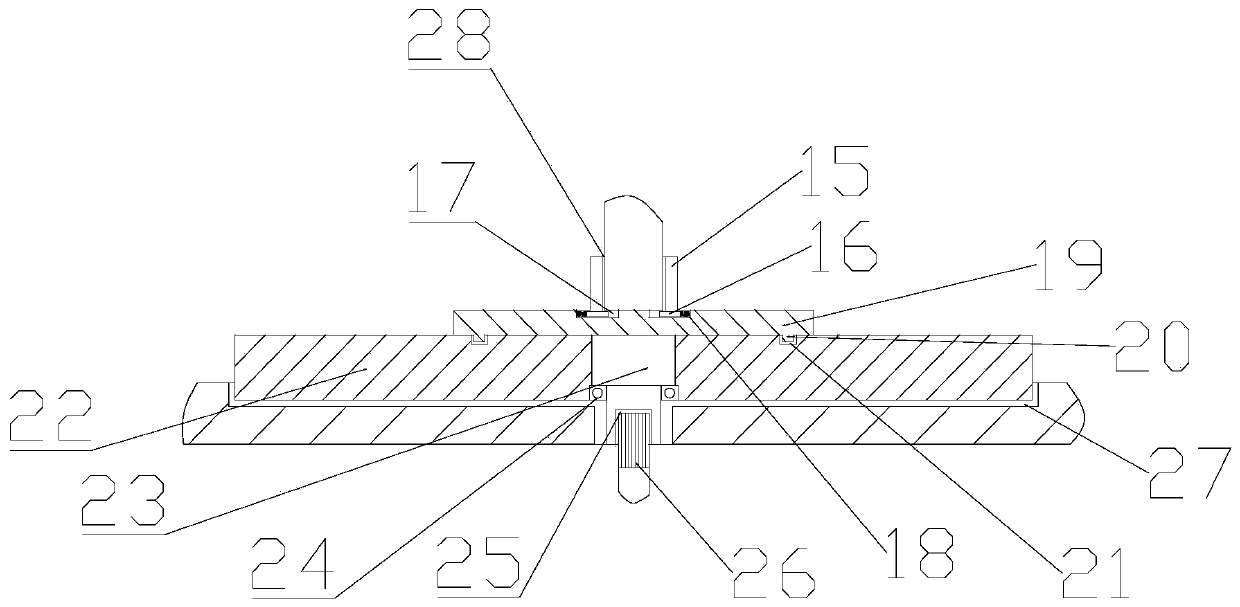

[0020] see image 3 , the fixing mechanism 14 includes a fixing plate 15, a slider 16, a chute 17 and a spring 18, the bottom of the fixing plate 15 is welded and fixed on the upper end surface of the slider 16, and the lower end surface of the slider 16 is slidably installed on the In the chute 17, the chute 17 is opened on the mounting seat 19, the spring 18 is also placed in the chute 17, when installing the plate, only need to insert the plate into the left and right fixed plates 15 It is convenient and fast, and can be adapted to fix plates of different thicknesses; the fixing plate 15 is bonded with a backing plate 28 near the side of the plate, which plays a buffering and protective effect, and prevents the fixing plate 15 from directly pressing the plate to cause the plate Surface wear; the bottom of the mounting seat 19 is processed with an annular slider 20, the annular sliding block 20 is slidably installed in the annular chute 21, and the annular chute 21 is opened...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com