Method for carrying out reverse transportation on large air pipe in module

An in-module, large-scale technology, applied in transportation and packaging, conveyors, mechanical conveyors, etc., to achieve the effect of saving manpower, simple structure, and improving the efficiency of reverse transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

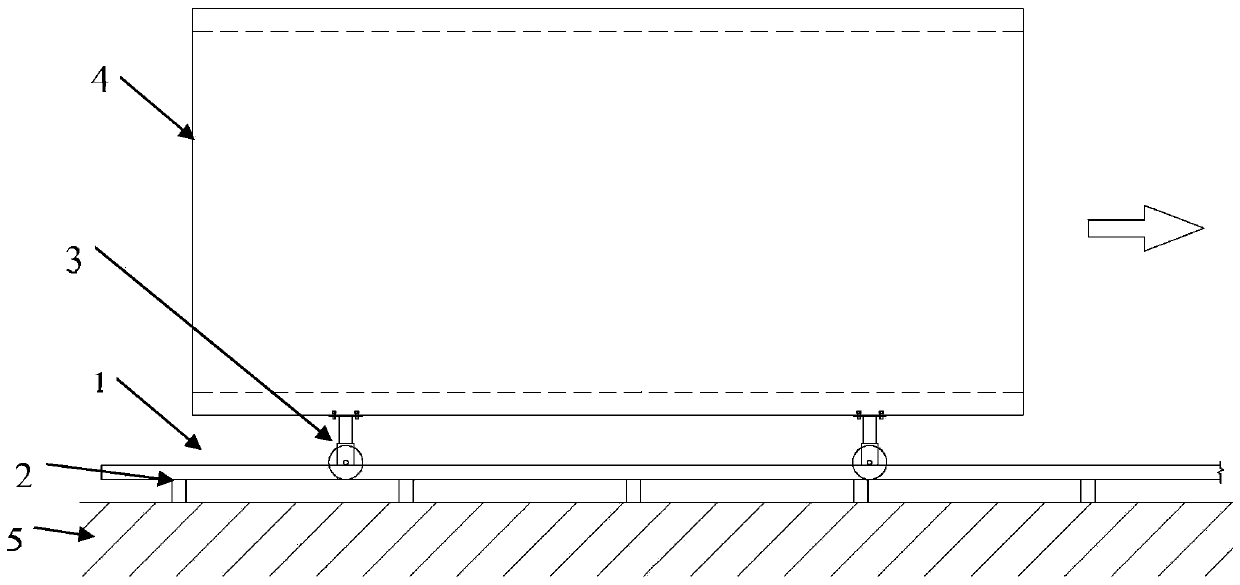

[0018] Such as figure 1 Shown, the present invention adopts following steps:

[0019] The first step: fix several slideway beams 1 (two in this embodiment) on the slideway support 2 above the deck layer 5 by spot welding;

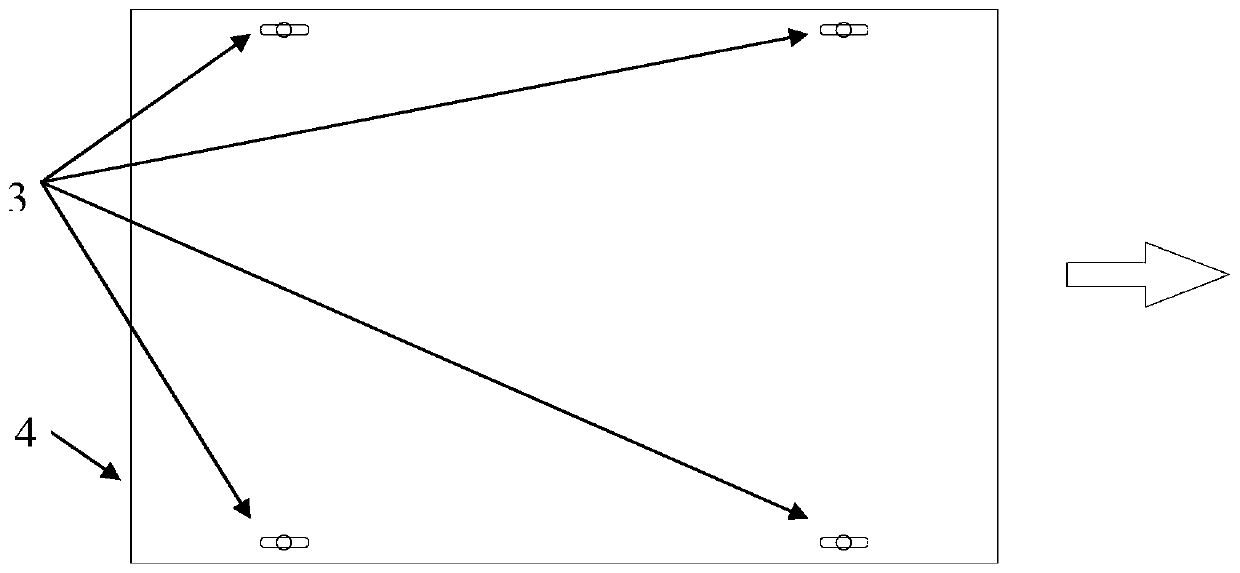

[0020] Step 2: Fix several rollers 3 under the large air duct 4 through bolt connection;

[0021] Step 3: Hoist the large air duct 4 equipped with the rollers 3 onto the slideway beam 1, and then move it to the inside of the large module to reverse the large air duct 4.

[0022] The above-mentioned slideway beam 1 is an angle steel, and can be bent according to the installation position of the large-scale air duct 4; The vertical state acts as a boundary guide for the pulley 3.

[0023] The above-mentioned slideway support 2 is angle steel or rib plate; the quantity of slideway support 2 is determined by the length of slideway beam 1 and the weight and length of large air duct 4;

[0024] The above-mentioned roller 3 has the functions of turning and sel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com