Waist tag automatic sewing machine

A sewing machine and sewing machine head technology, which is applied to sewing machine components, sewing equipment, cloth feeding mechanisms, etc., can solve the problems of large manpower demand and low operation efficiency, and achieve the effect of improving sewing processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

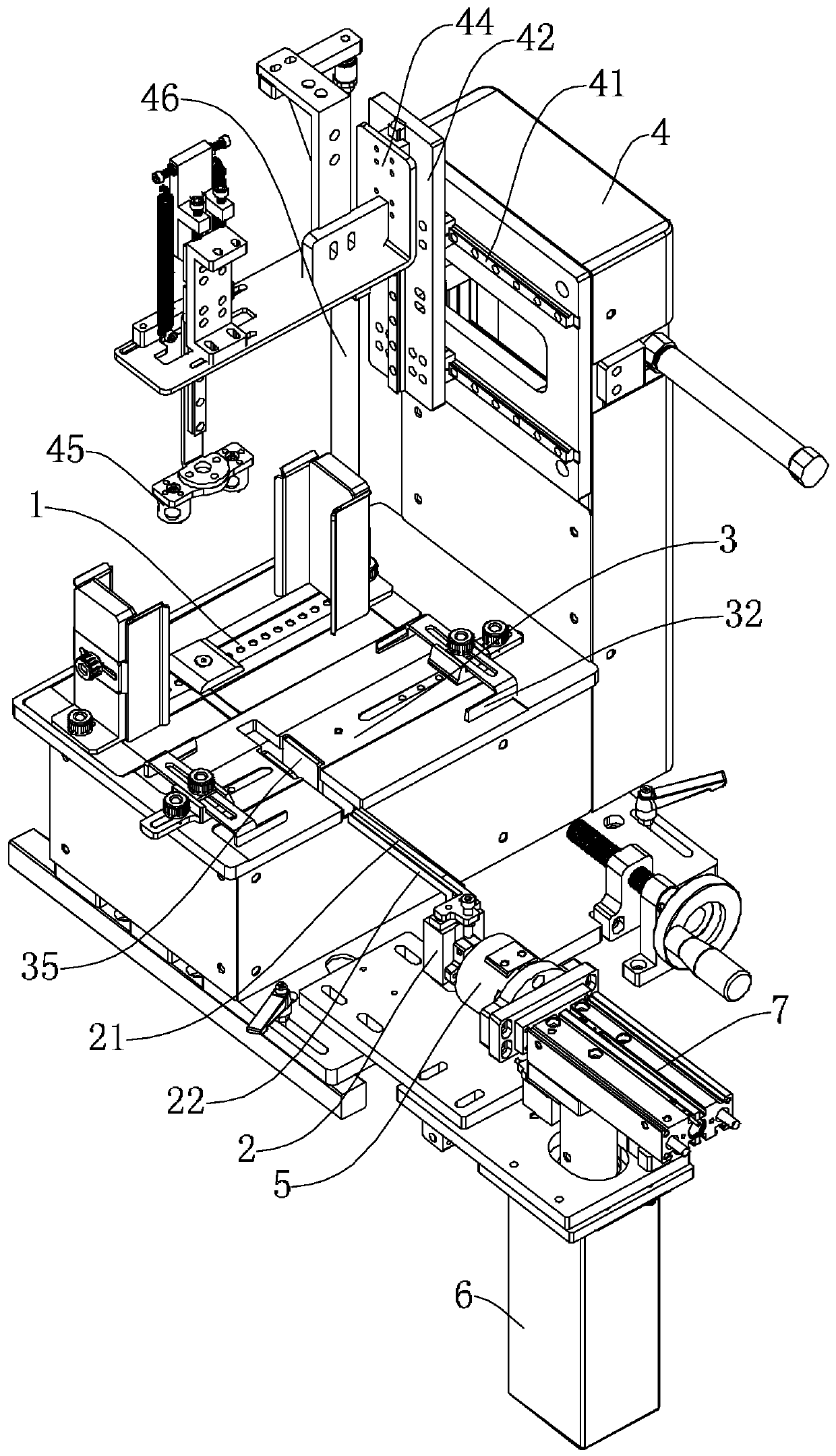

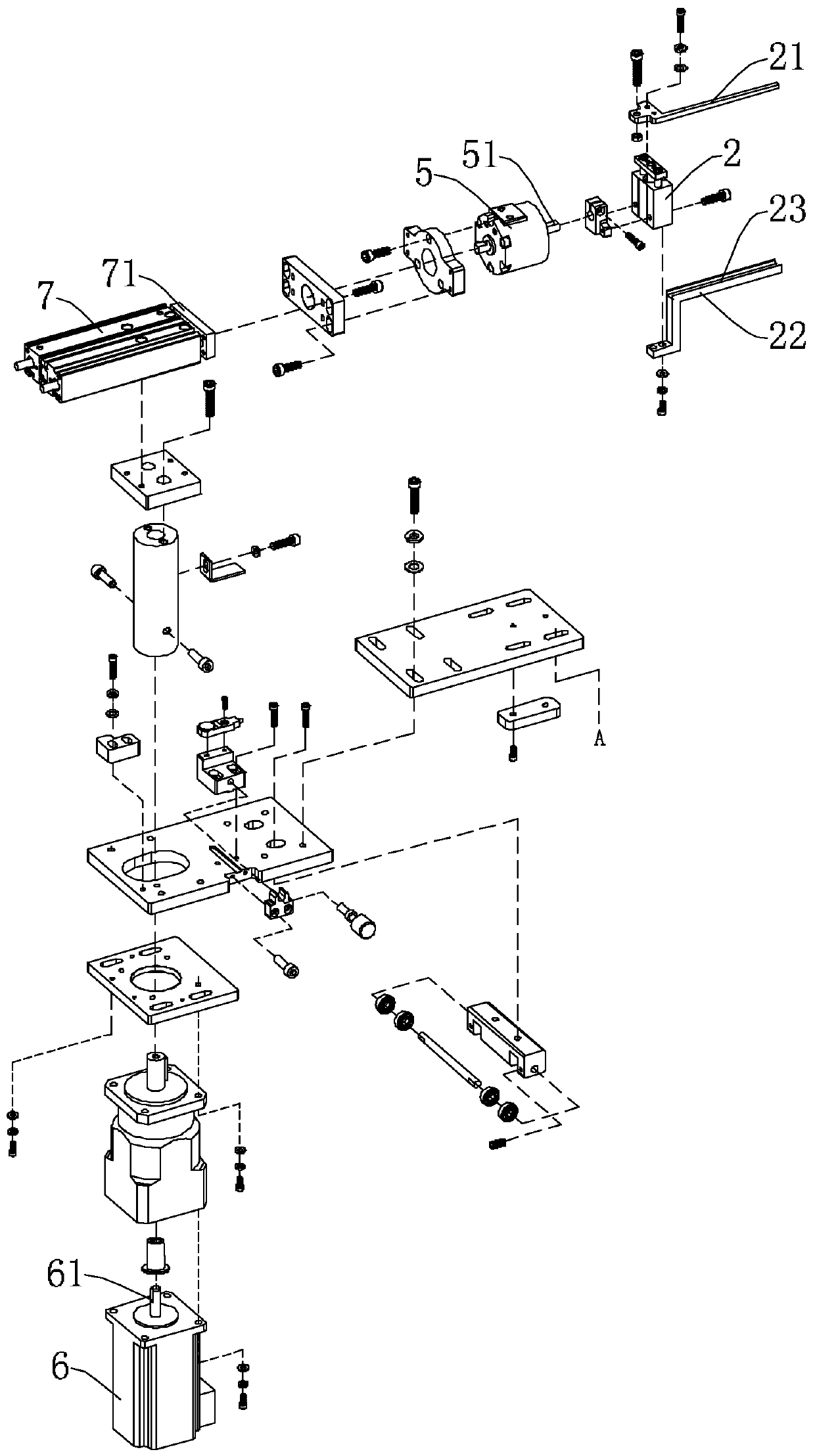

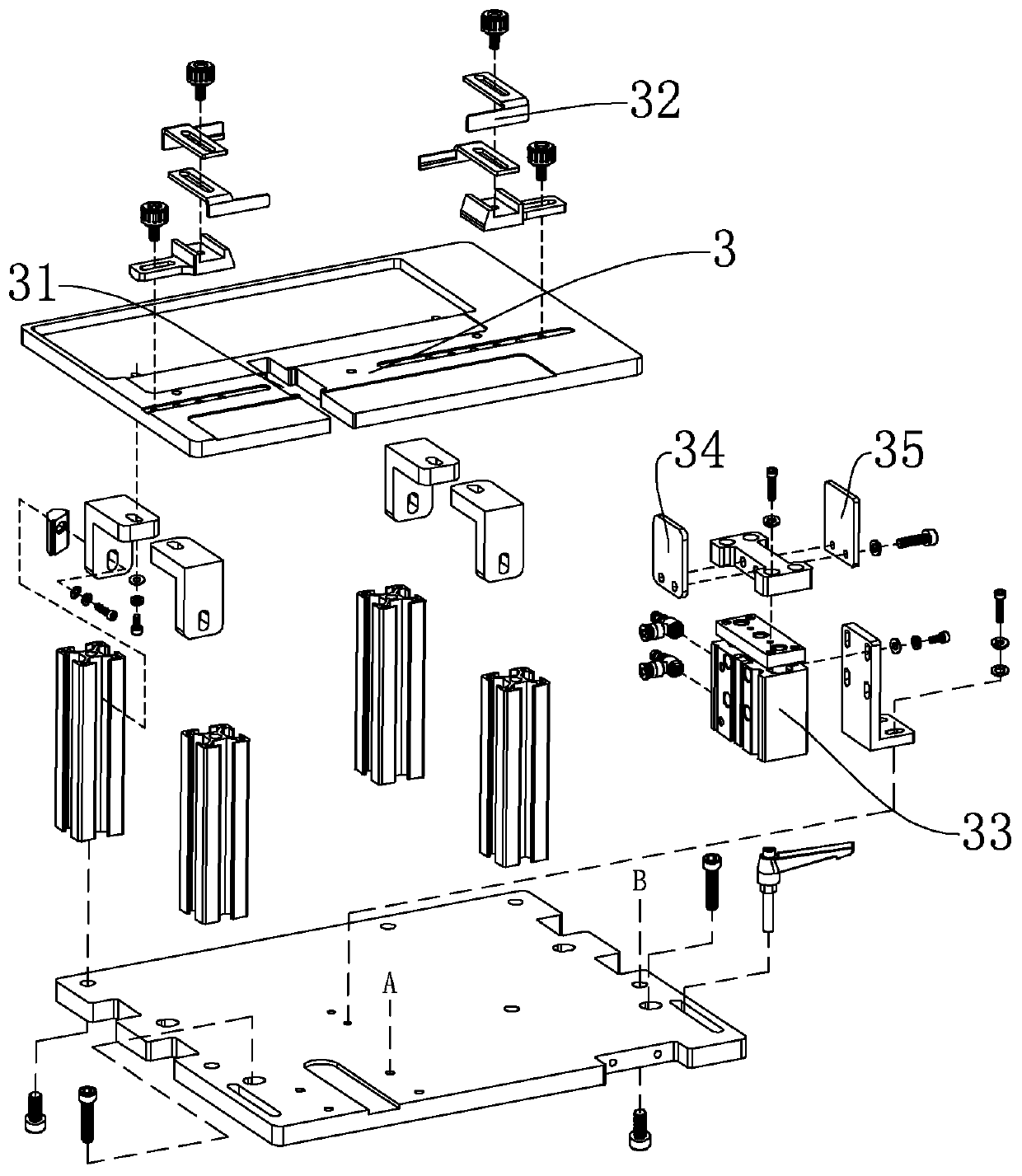

[0019] Figure 1 to Figure 4 Shown is the structural representation of the present invention.

[0020] The reference signs are: silo 1, clamping drive cylinder 2, upper splint 21, lower splint 22, folding groove 23, support plate 3, clamping groove 31, limit plate 32, auxiliary folding cylinder 33. The first auxiliary folding plate 34, the second auxiliary folding plate 35, the bracket 4, the transverse guide rail 41, the transverse sliding seat 42, the transverse cylinder 43, the lifting seat 44, the sucker assembly 45, the reclaiming cylinder 46, the first rotating Driver 5, first rotating shaft 51, second rotary driver 6, second rotating shaft 61, linear feeding cylinder 7, feeding driving rod 71, sewing machine head 8, sewing presser foot 81, sewing support plate 82, movable pallet 83, mounting seat 9. Horizontal moving cylinder 91, mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com