Leak-proof liquid pipeline flange

A pipeline flange and anti-leakage technology, which is applied in the direction of flange connection, pipe/pipe joint/pipe fitting, passing components, etc., can solve the problem of not being able to effectively strengthen the connection between the left flange and the right flange, and not being able to reduce the liquid on the left There are problems such as impact on the joint surface of the flange and the connecting pipe, and no anti-shock device is installed, so as to reduce the impact, increase the sealing performance, and enhance the sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

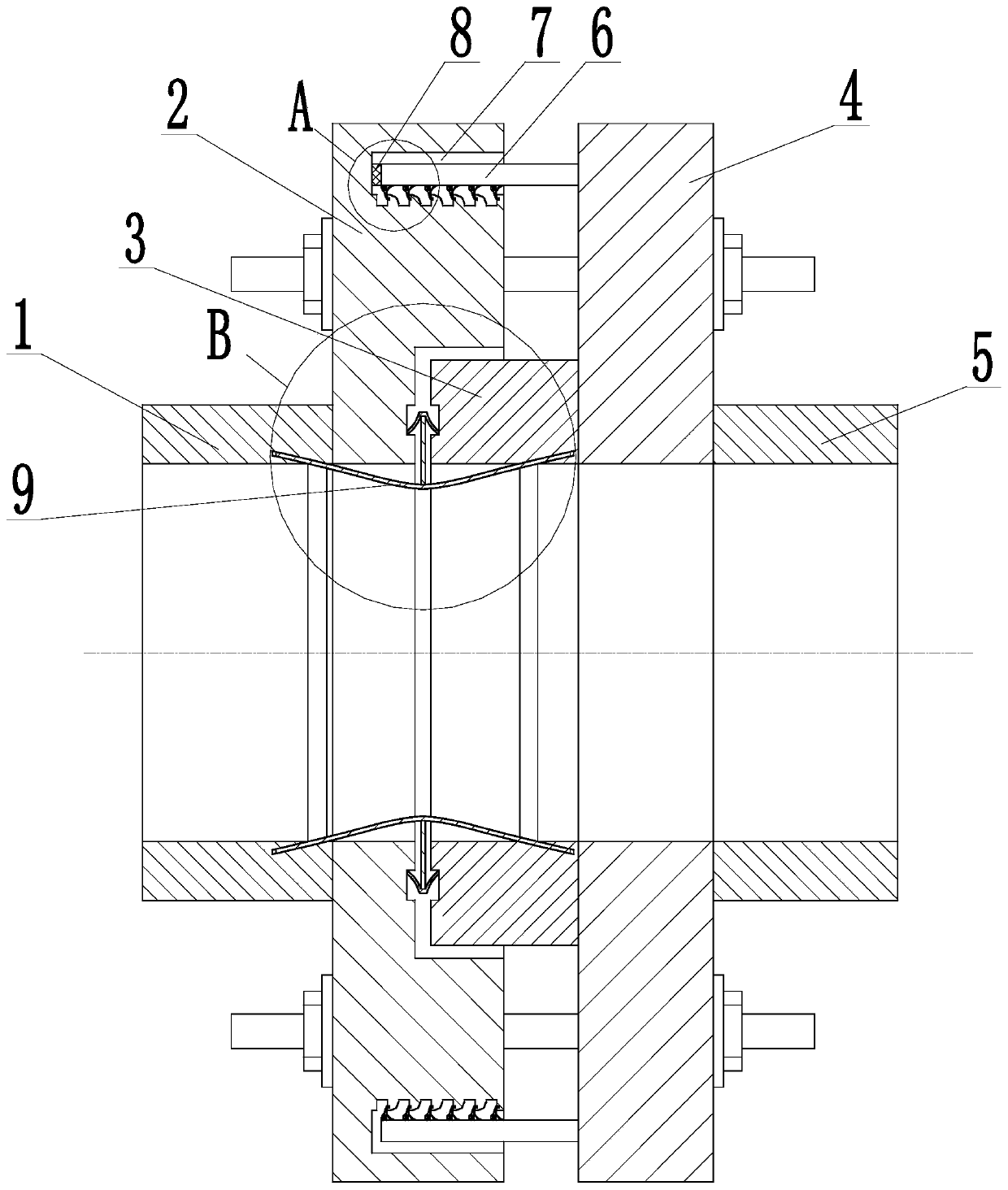

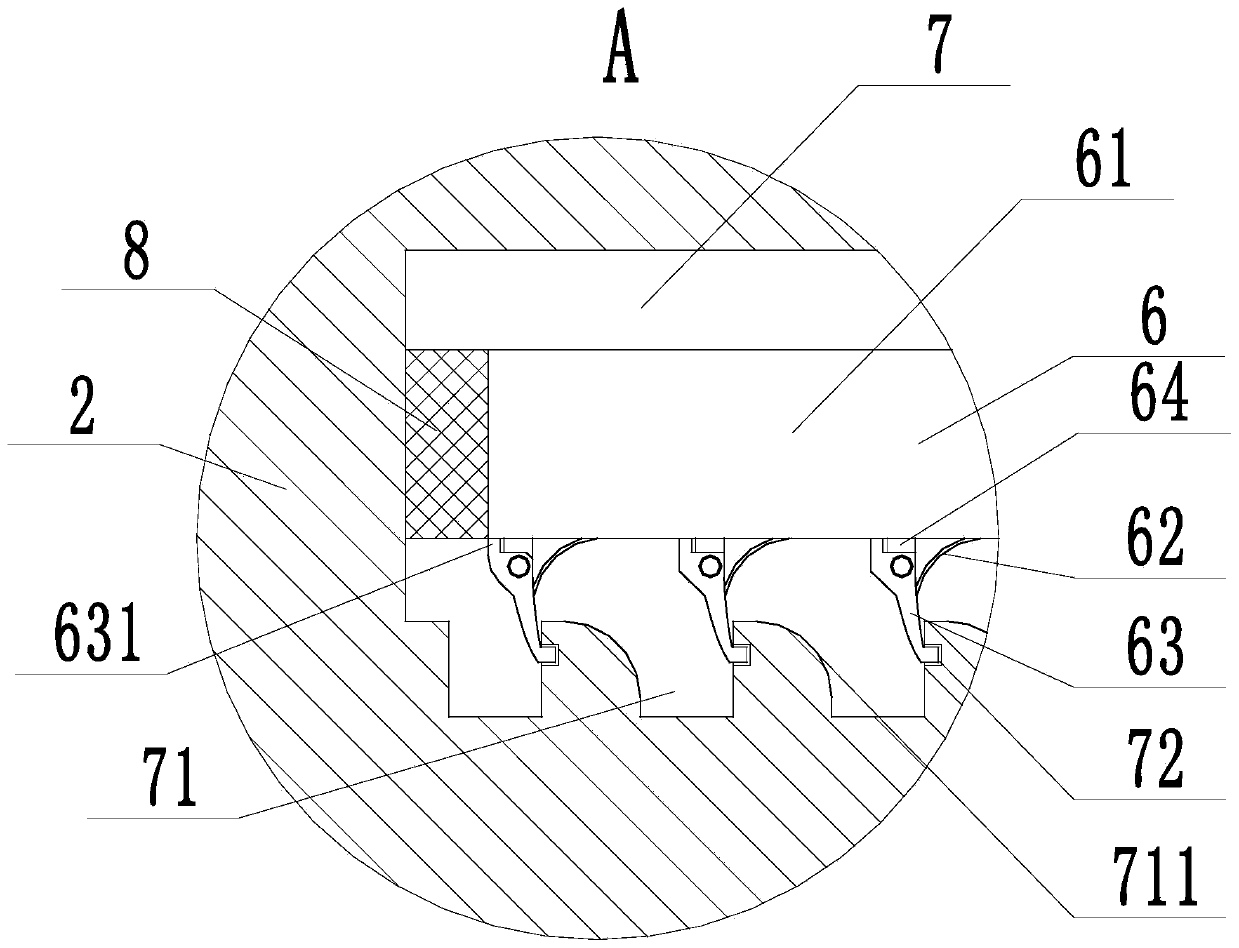

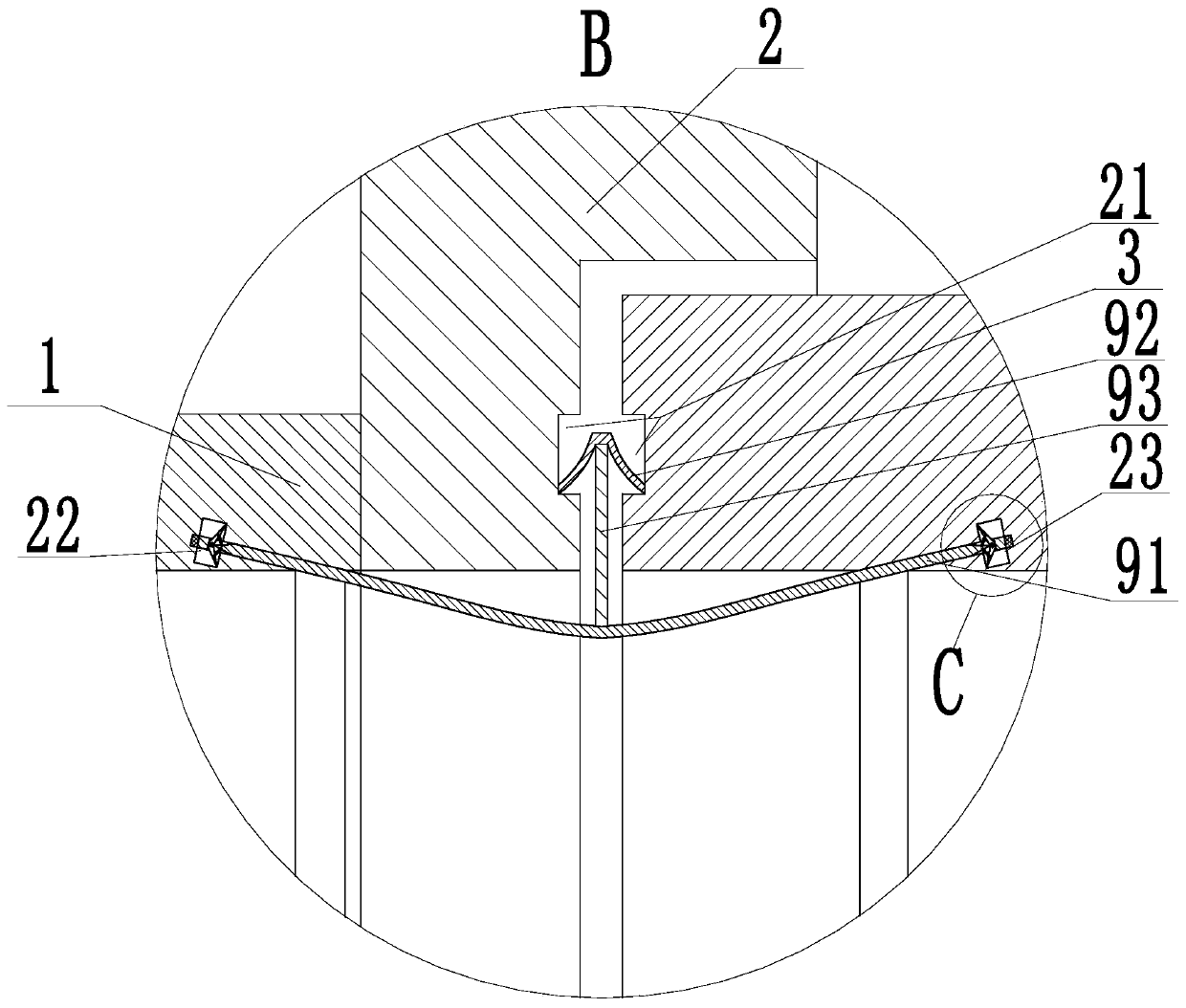

[0023] use Figure 1 to Figure 4 A liquid leakage prevention pipe flange of the present invention is described as follows.

[0024] Such as Figure 1 to Figure 4 As shown, a liquid leakage prevention pipeline flange according to the present invention includes a water inlet pipe 1, one end of the water inlet pipe 1 is fixedly installed with a left flange 2, and the other end of the left flange 2 is movably socketed with a A connecting pipe 3, the other end of the connecting pipe 3 is fixedly installed with a right flange 4, the other end of the right flange 4 is fixedly installed with an outlet pipe 5, the outer surfaces of the left flange 2 and the right flange 4 Holes are opened, and the left flange 2 and the right flange 4 are fixedly connected by bolts, the number of the bolts is at least 8, and the bolts are distributed in a circular equidistant manner on the left flange 2 and the right flange 4, one end of the right flange 4 is fixed with an auxiliary clamping module 6, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com