A combined flame stabilizer with adjustable concave cavity vortex structure and its working method

A flame stabilizer, adjustable technology, applied in the direction of combustion method, lighting and heating equipment, continuous combustion chamber, etc., can solve the problems of insufficient flameout performance at lean point, high ignition and flame stability performance, etc., to ensure flame stability performance , widen the limit of flameout, and accelerate the effect of spreading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

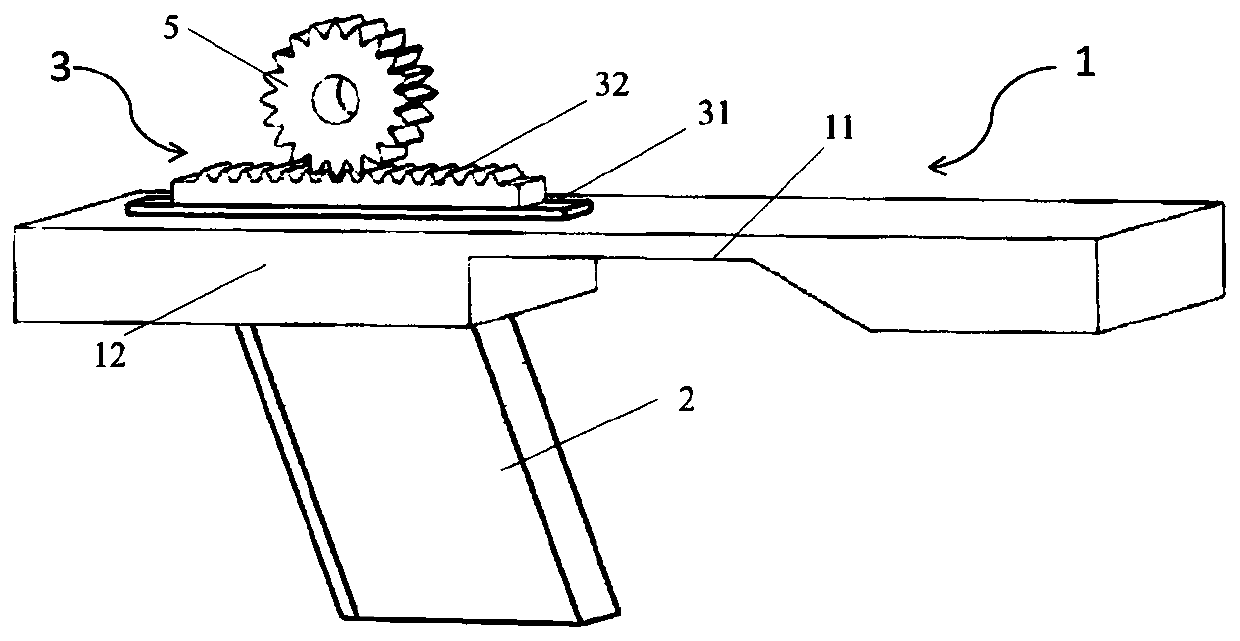

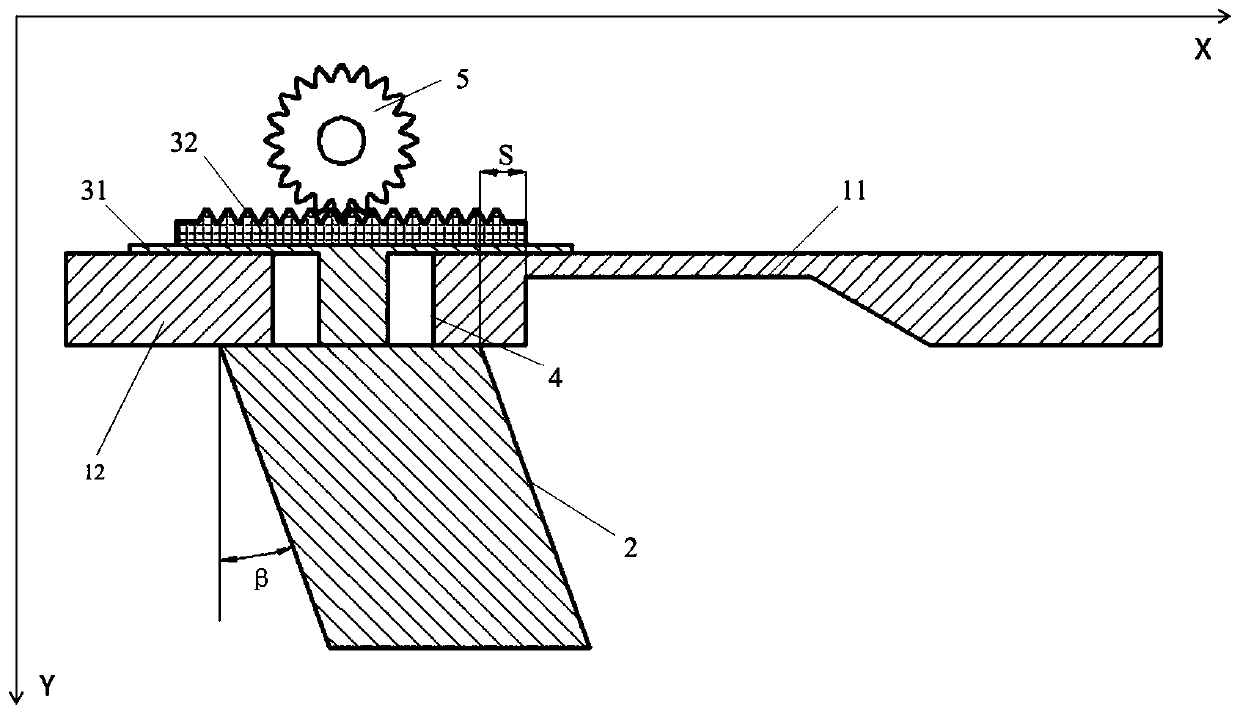

[0023] Embodiment 1: as figure 1 As shown, the combined flame stabilizer of the adjustable cavity vortex structure of the present invention, the combined flame stabilizer is composed of an outer concave cavity flame stabilizer 1, a radial flame stabilizer 2, and is used to adjust the radial flame stabilizer 2 is composed of an adjustment mechanism 3 relative to the axial relative position of the outer cavity flame stabilizer 1 and a guide groove 4 for limiting the axial maximum travel of the adjustment mechanism 3 .

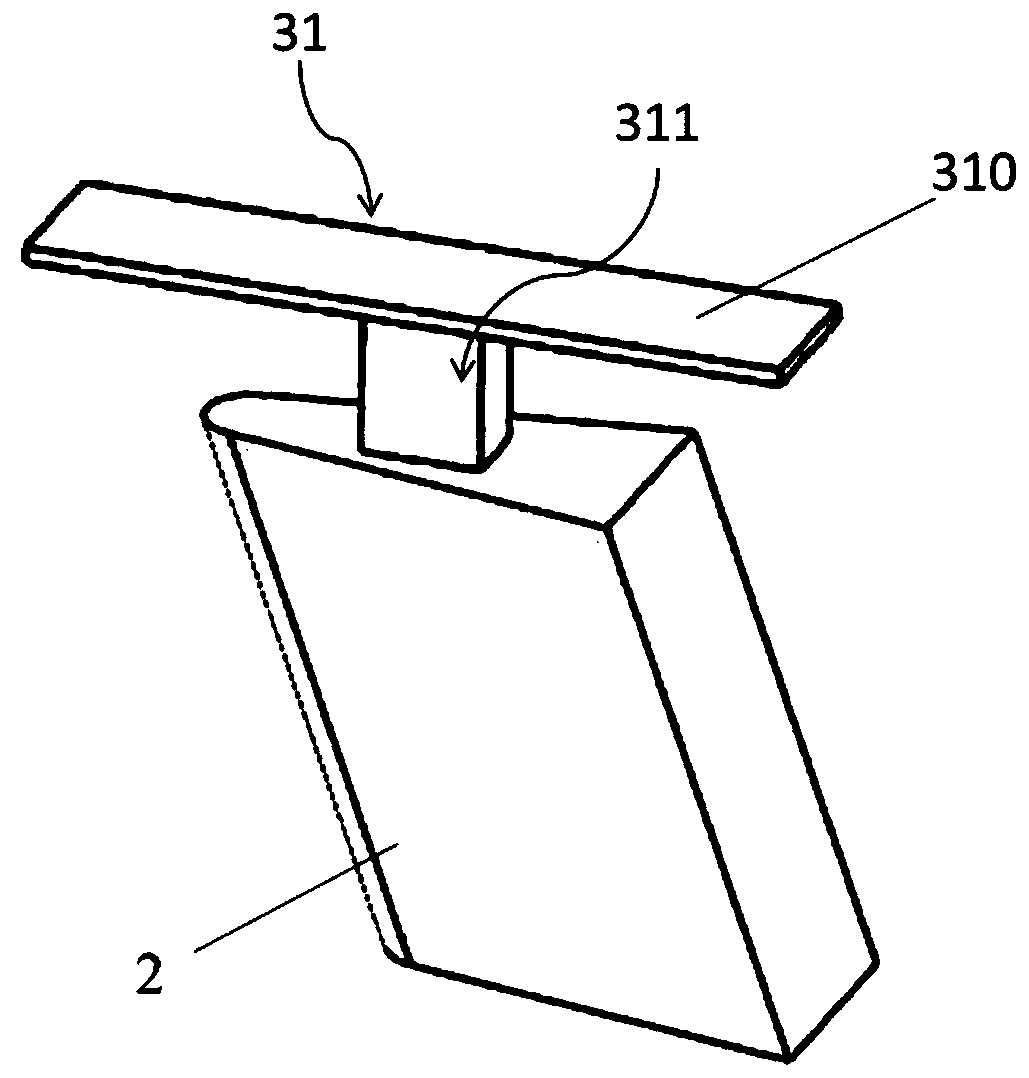

[0024] The outer cavity flame stabilizer 1 is composed of a horizontal section 12 extending horizontally at the front end and a cavity section 11 at the rear end of the horizontal section 12. A guide groove 4 is opened on the horizontal section, and the guide groove 4 runs through the thickness direction of the horizontal section 12. One end of the adjustment mechanism 3 is located on the outer wall of the horizontal section, and the other end passes through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com