Installation device for mounting in ceiling

A ceiling and installer technology, applied in the parts of lighting devices, lighting devices, supporting machines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

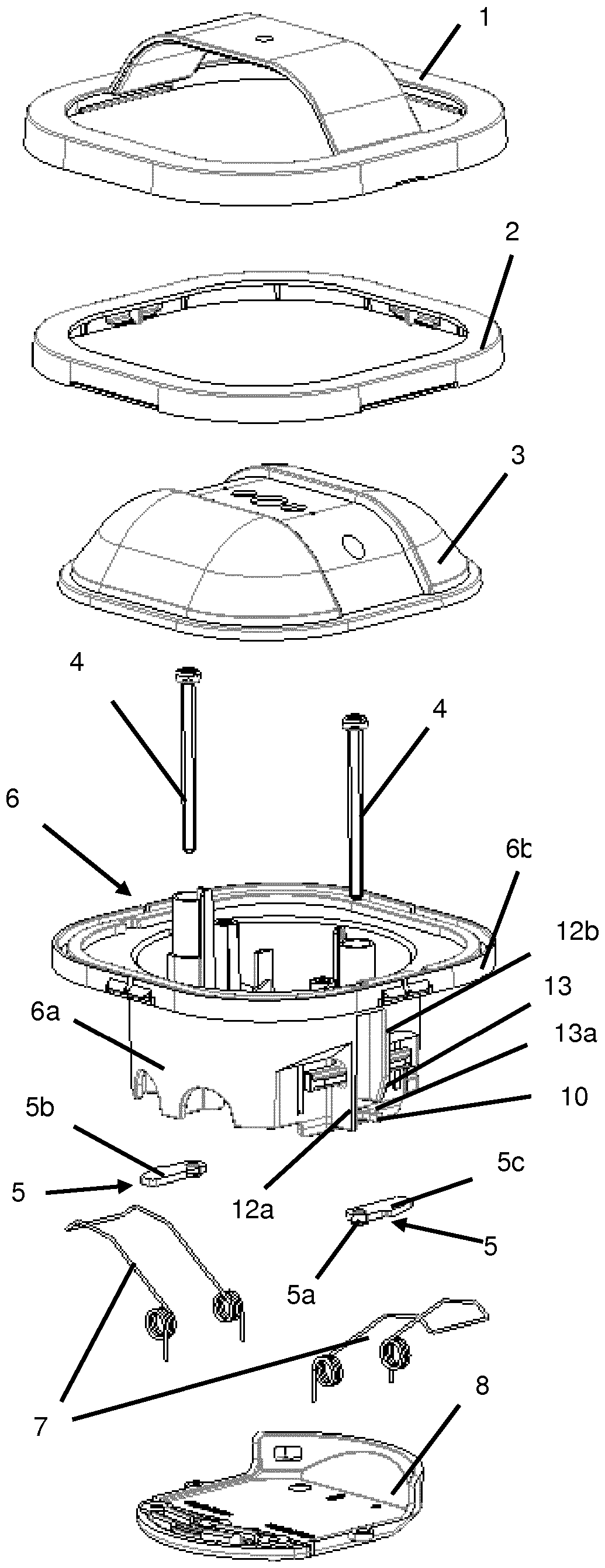

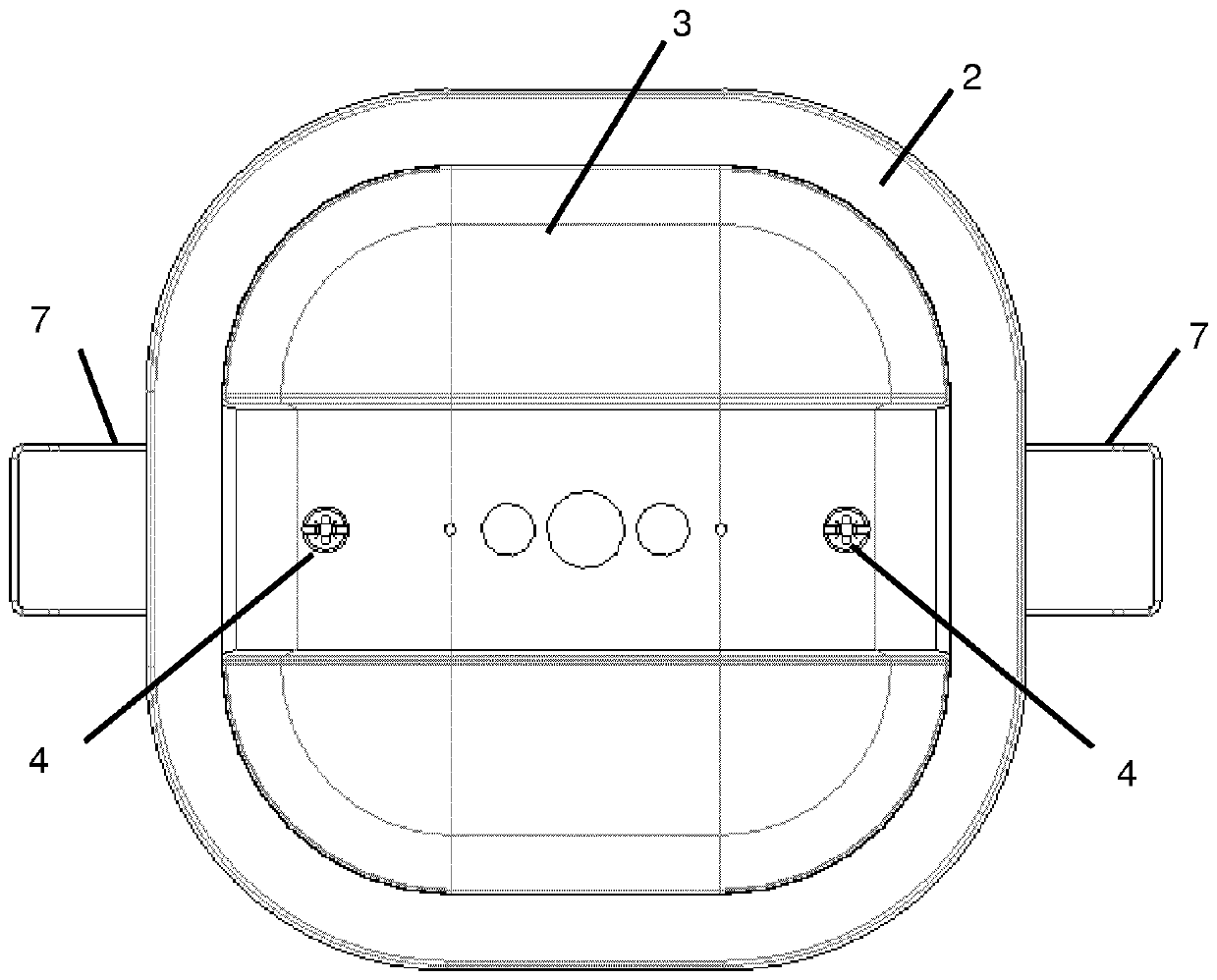

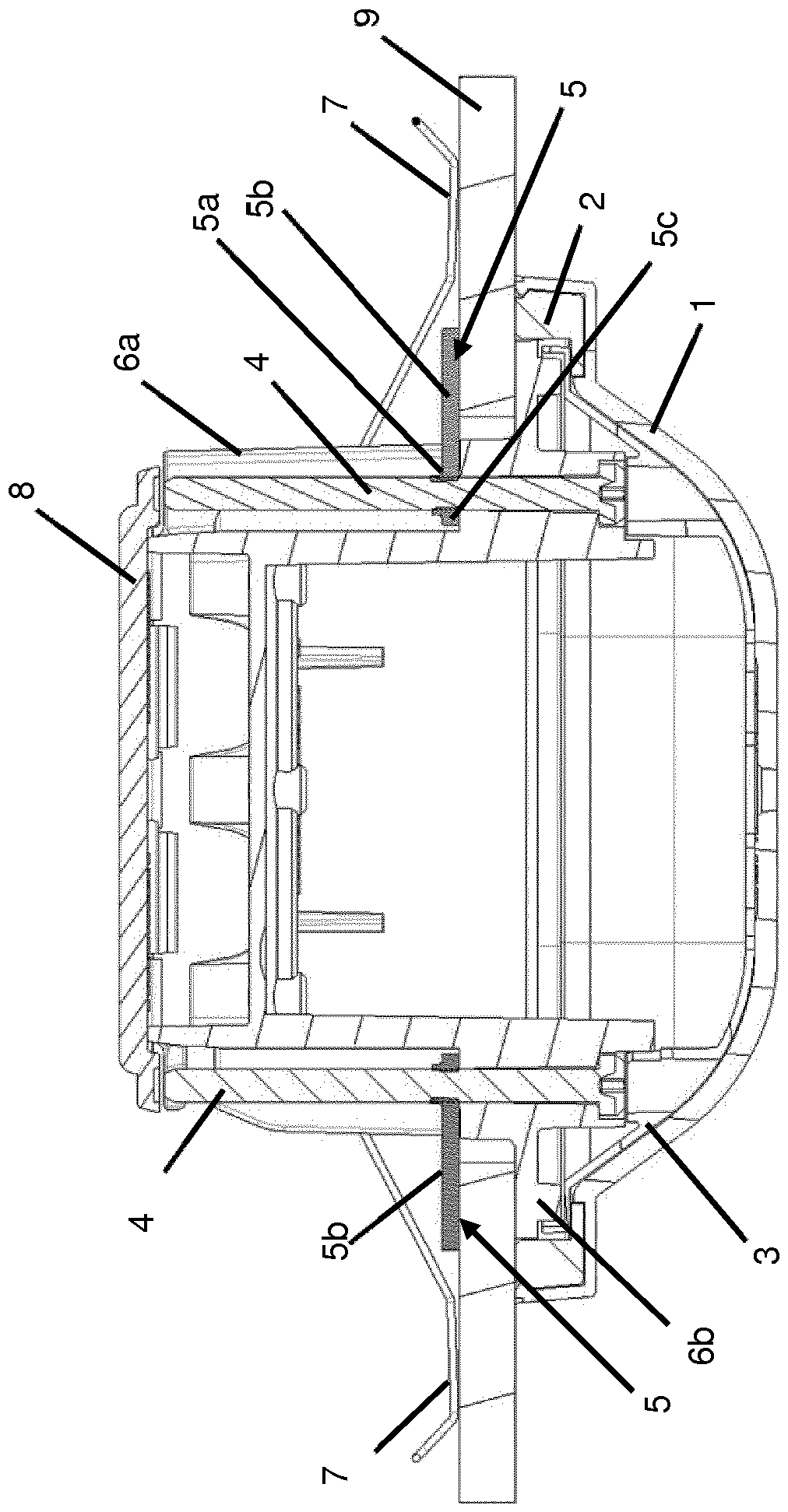

[0026] as in Figures 1 to 6As shown in , the mounter for fitting in the only partly shown opening 16 of a ceiling 9 formed of a plate-like material such as, for example, wood or plasterboard and having an inner space 17 and an outer space 18 comprises a housing Body 6, which has a first housing section 6a. The first housing section 6 a has a smaller diameter than the opening 16 . Furthermore, a flange-like second housing section 6 b is formed on the housing 6 , which has an enlarged diameter relative to the opening 16 and which rests flush against the first housing section 6 a after being pushed in. At the bottom surface of the ceiling 9, when the first housing section 6a is as in figure 2 when fully pushed into the opening as shown in . In the region of the first housing section 6a, two diametrically opposite opening arms 7 are pivotably fixed, which are radially extended by means of spring elastic means in the form of coil springs which are not shown in more detail. lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com