Online traction steel wire rope tensioning force unevenness detection device and work method thereof

A detection device, wire rope technology, applied in the directions of tension measurement, transportation and packaging, elevators, etc., can solve the problems of large influence of human factors and poor accuracy, and achieve the effect of saving installation space, strong practicability and tight layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing, the present invention will be further described

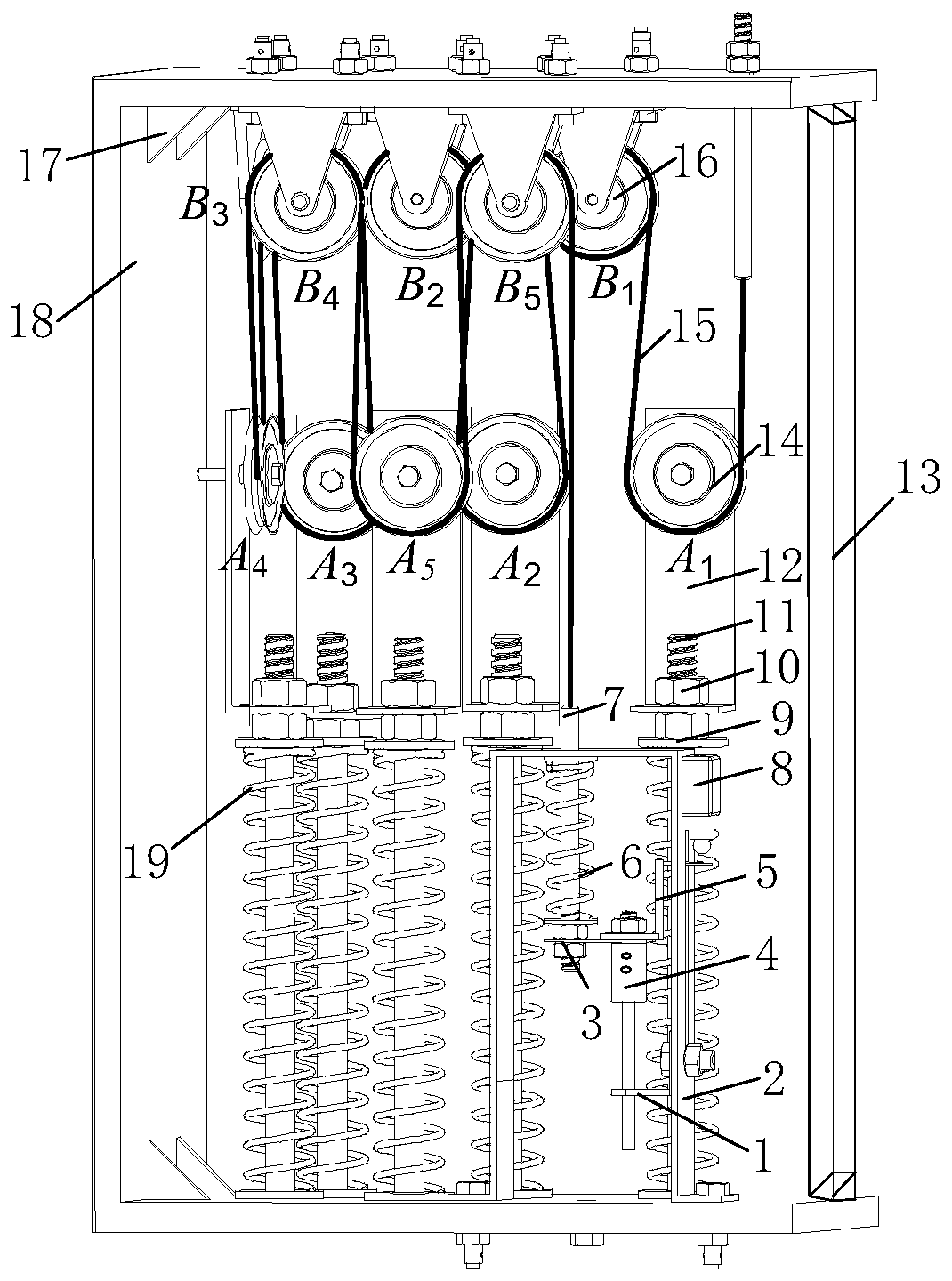

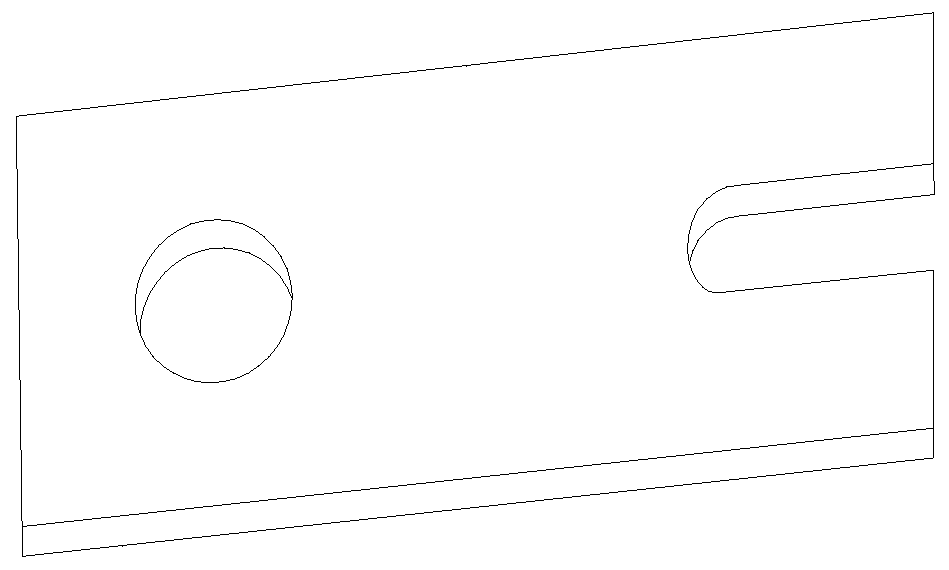

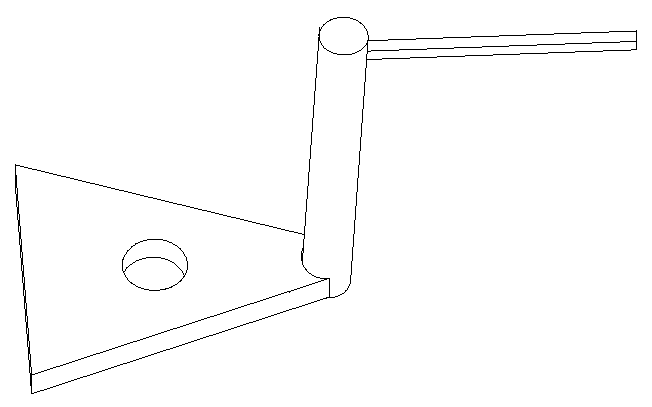

[0028] see Figure 1 to Figure 6 , the present invention provides an on-line detection device for uneven tension force of a traction steel wire rope, comprising a traction elevator steel wire rope rope end spring 6 adjustment assembly, a steel wire rope connection assembly, a displacement monitoring assembly and a U-shaped installation frame 18; the U-shaped installation frame 18 openings face to the right, and the bottom of the U-shaped mounting frame 18 is provided with several type mounting frames 2, and the top of the several type mounting frames 2 is provided with a first through hole, and the right side of the mounting frame is provided with a strip Shaped second through hole, the rope end spring 6 adjustment assembly is installed in the first through hole, the traction wire rope 15 rope end spring 6 adjustment assembly includes a rope end spring 6, a rope end screw r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com