Testing device for prestressed anchor group type retaining wall

A test device and prestressing technology, applied in the direction of measuring device, using stable tension/pressure test material strength, instruments, etc., can solve the problems of cumbersome operation, large error, and difficulty in accurately obtaining the real stress of the anchor cable, etc. Highly reproducible and easy-to-operate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to enable those skilled in the art to better understand the present invention, the following will clearly and completely describe the technical solutions in the embodiments of the present invention. Obviously, the described embodiments are only a part of the present invention, rather than Full examples.

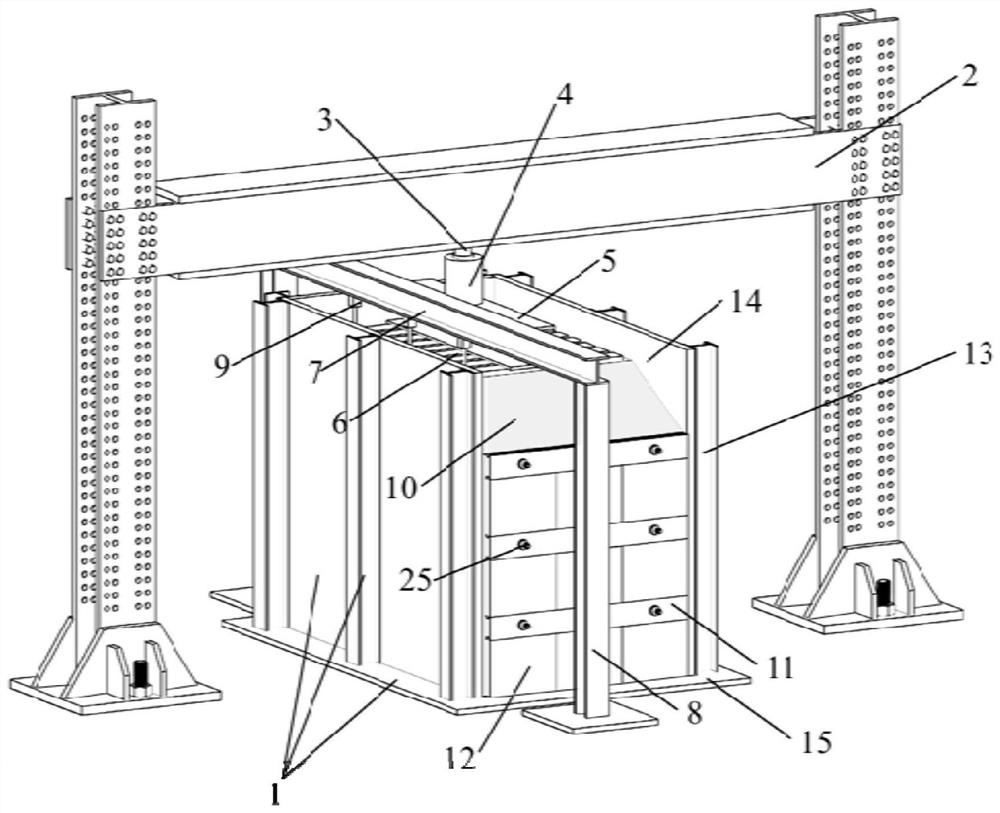

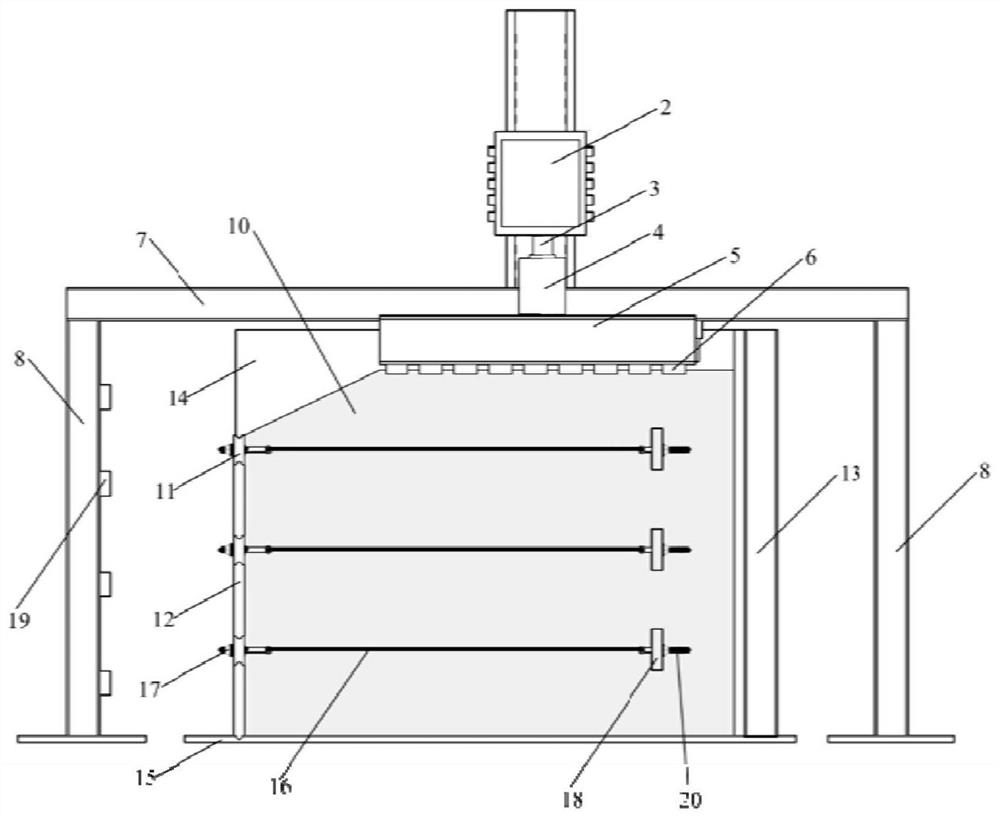

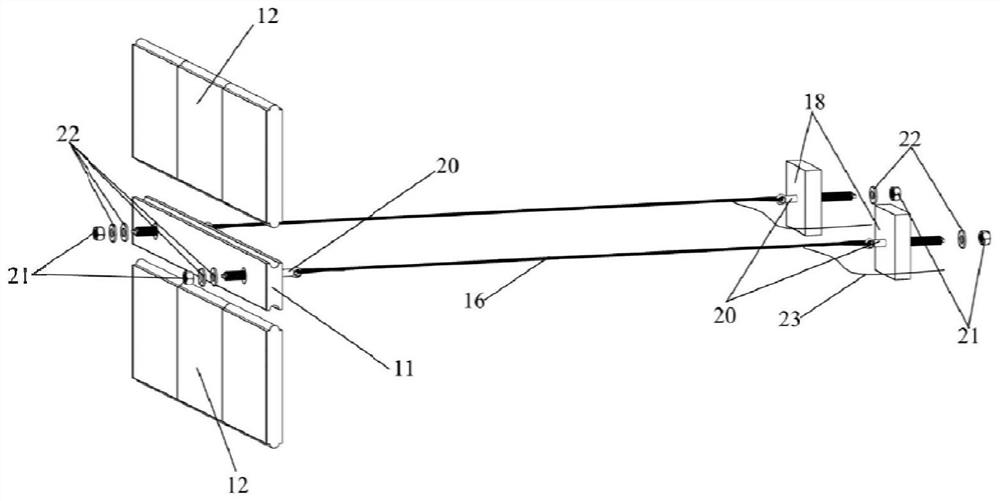

[0023] The embodiment of the present invention provides a test device for a prestressed group anchor type retaining wall, including a model box 1, a loading system, and a prestress detection system. The detection system is installed in the packing chamber, and the prestress detection system includes a self-sensing anchor cable 16 and an anchor plate 18, one end of the self-sensing anchor cable 16 is connected with the model box 1, and the anchor plate 18 is installed on the self-sensing anchor cable 16. At the other end of the anchor cable 16, the loading system includes a pressing member 5, and the pressing member 5 is located at the opening of the stuffing c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com