Intelligent suturing device

A sewing device and intelligent technology, applied in sewing machine control devices, tension devices, sewing equipment, etc., can solve the problems of saving manpower and inconvenience, and achieve the effects of standardized production, reduced friction, high sensitivity and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

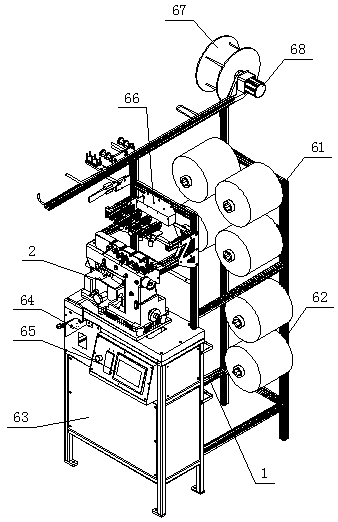

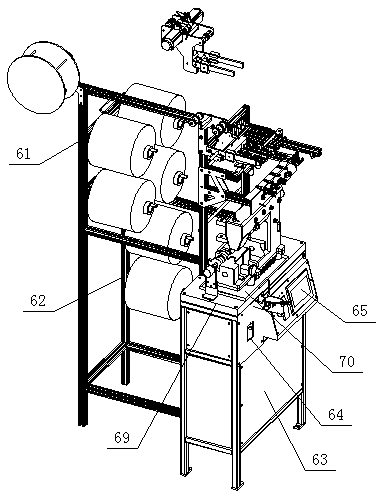

[0031] Such as Figure 1-2 As shown, a kind of intelligent sewing device comprises frame 1, and described frame 1 is provided with control mechanism, sewing mechanism 2, yarn feeding mechanism, bobbin thread feeding mechanism, cloth tape feeding mechanism and plastic chain feeding mechanism mechanism, the control mechanism includes an electric control cabinet 63 and a control panel 64 coordinated with it, a PLC control system and a touch display 65, and the built-in software of the PLC control system can display and record the operating status of the machine in real time, including: machine number, Product model, machine speed, effective start-up time, output, yarn tension change and shift information, etc., are uploaded to the terminal server, connected to the ERP system, and realize enterprise big data production and quality control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com