Device for monitoring tension force of mooring anchor chain

A technology for monitoring devices and mooring anchors, applied in the direction of tension measurement, measuring devices, measuring force, etc., can solve the problems of high cost, complex implementation process, poor versatility, etc., and achieve the effect of simple structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention will be described below.

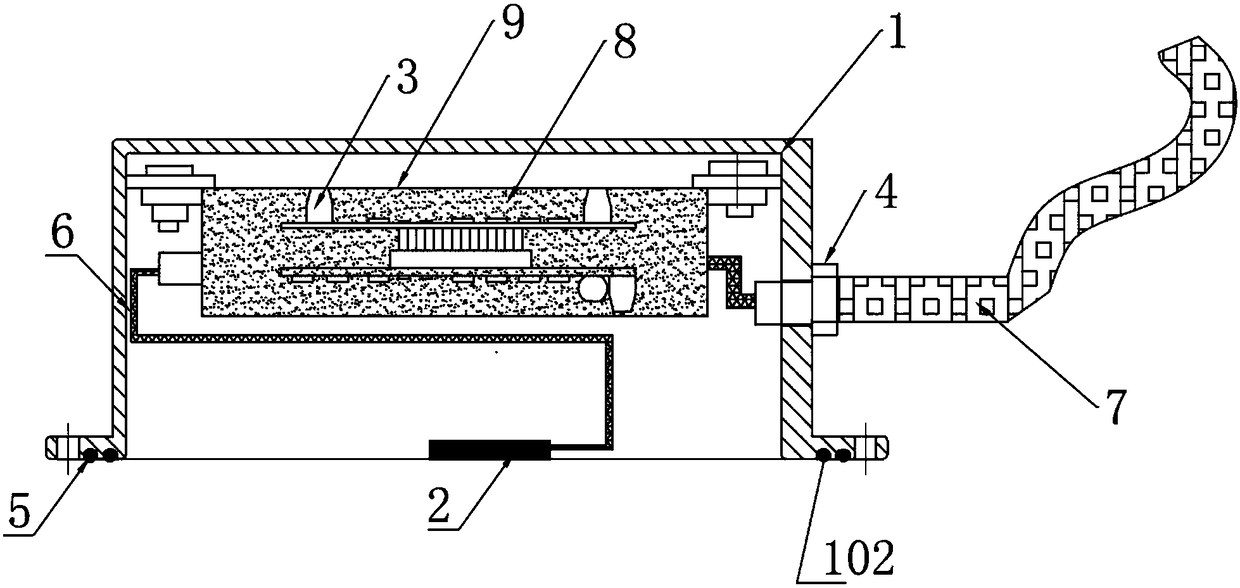

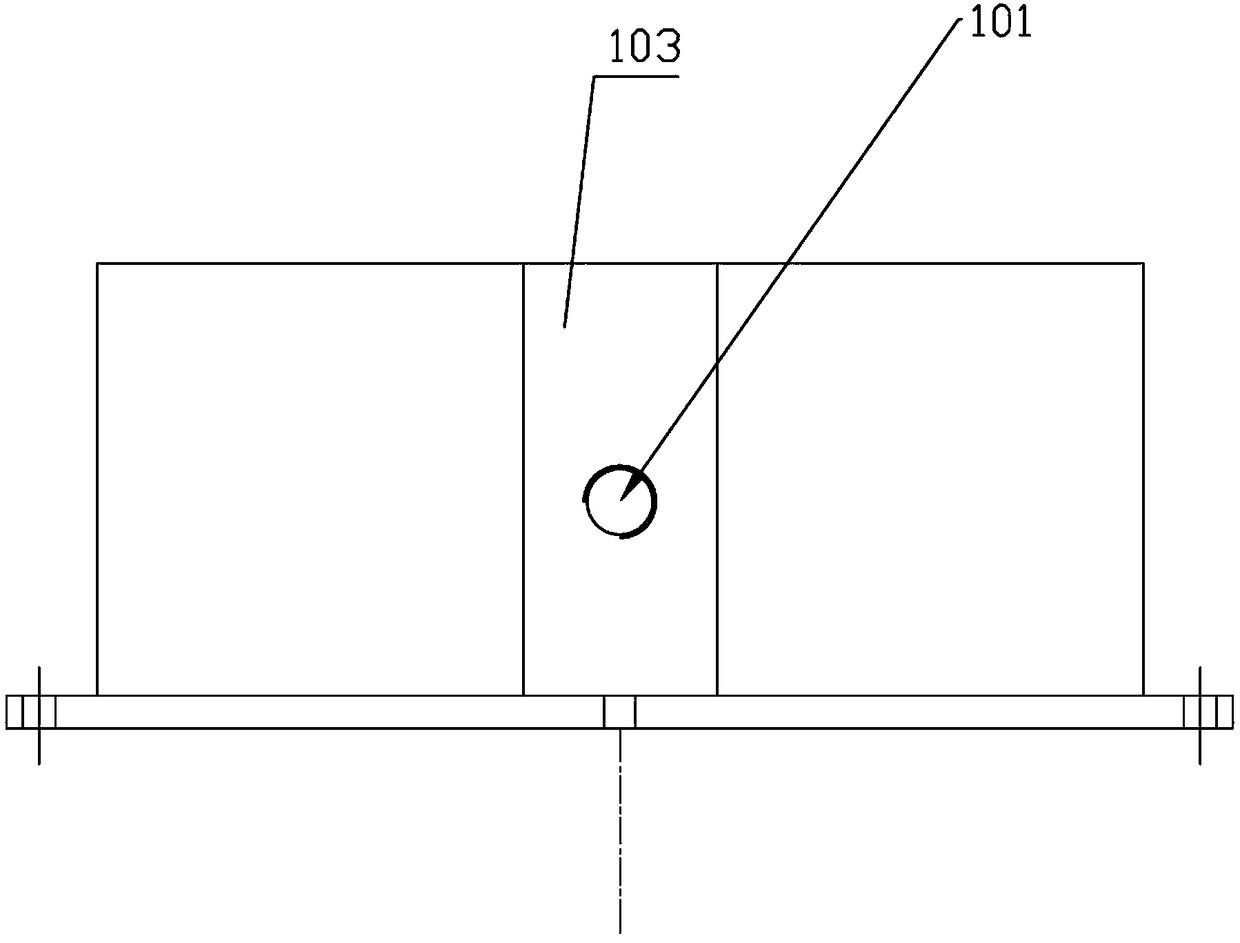

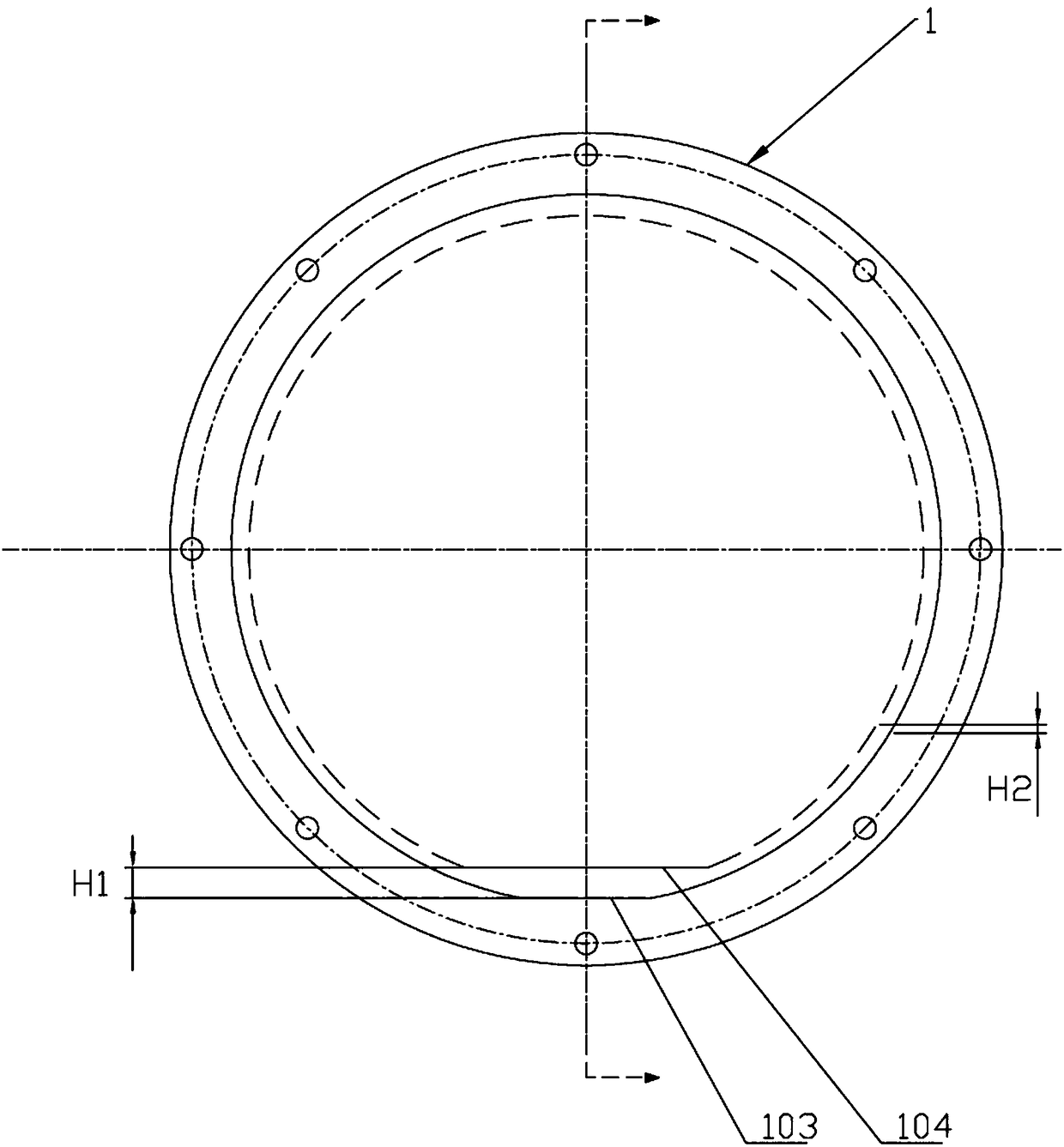

[0021] Such as figure 1 As shown, the mooring anchor chain tension monitoring device of the present invention includes a watertight pressure-bearing shell 1 with a cavity, and the watertight pressure-bearing shell 1 is made of 316L stainless steel. A one-way full-bridge strain sensor 2 and a vulcanized mold plate metal shell 9 are arranged in the cavity of the watertight pressure-bearing shell 1. The one-way full-bridge strain sensor 2 is a weldable 350 ohm strain gauge for use inside the mooring anchor chain Sensing of tension. The signal acquisition communication circuit board 3 is placed in the inside of the vulcanization mold plate metal shell 9, and polyurethane resin glue 8 potting is set in the inside of the vulcanization mold plate metal shell 9. The signal acquisition communication circuit board 3 in the present invention is a circuit module with a power of 0.35 watts and a volume of 60m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com