A miniature bare optical fiber automatic reel system

A technology of bare optical fiber and reel, which is applied in the field of miniature bare optical fiber automatic reel system, which can solve problems such as easy failure, small diameter of bare optical fiber, fast response of rewinding speed, influence of bare optical fiber uniformity and integrity, etc., to meet the requirements of winding and cable system requirements, good speed regulation and positioning control performance, and good open-loop follow-up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

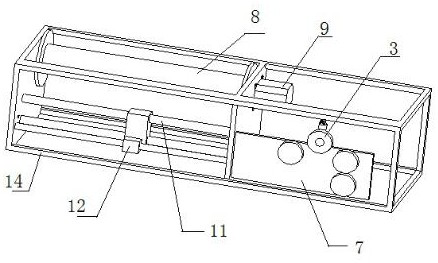

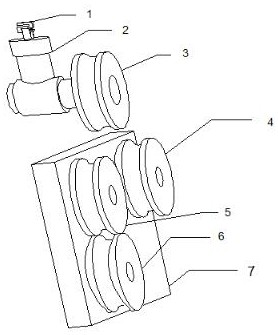

[0041] A kind of miniature bare optical fiber automatic reel system provided by the present embodiment, such as figure 1 , including a mechanical support 14, a reel set, a pulley set, a linear bearing 2, a data acquisition module, a pulley set support 7 and a main control subsystem, wherein:

[0042] The mechanical support 14 includes a left support surface and a right support surface;

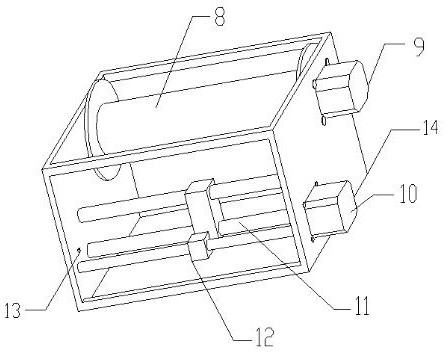

[0043] reel sets such as image 3 , including a winding subsystem and a wiring subsystem, the winding subsystem and the wiring subsystem are fixed in the mechanical support 14;

[0044] The winding subsystem includes a reel 8 and a first stepping motor 9, the first stepping motor 9 is fixedly connected to the reel 8, the bottom surface of the reel 8 is fixed on the left support surface of the mechanical support 14, and the first stepping motor 9 is fixed on the mechanical The right supporting surface of the support 14 controls the speed at which the reel 8 winds or releases the bare optical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com