Follow-up power supply equipment of wharf shore power supply system

A technology of power supply system and power supply equipment, applied in substation/distribution device casing, electrical components, substation/switch layout details, etc. Difficult to move and other problems, to achieve the effect of improving flexibility, reducing labor intensity and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

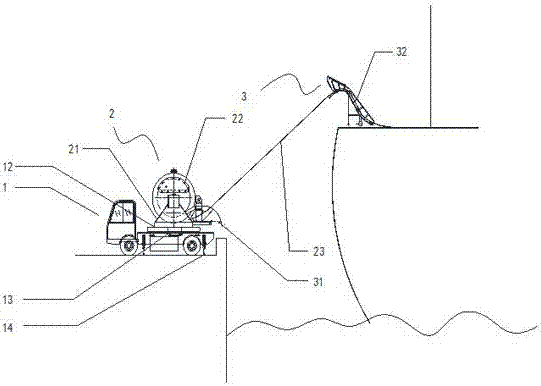

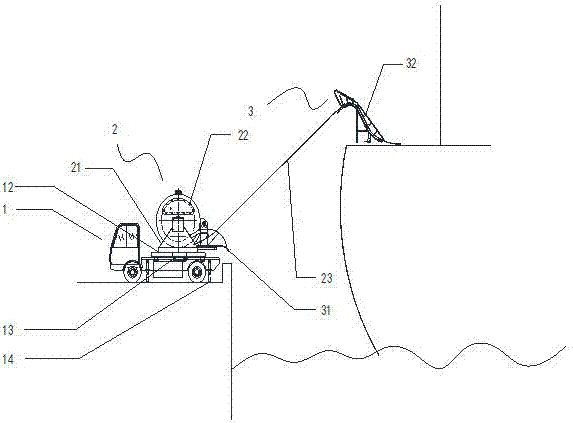

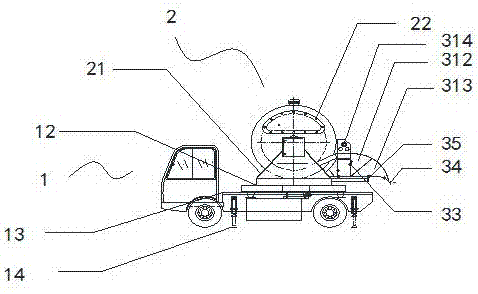

[0031] Such as Figure 1 to Figure 6 The follow-up power supply equipment of a wharf shore power supply system shown includes a mobile carrier 1 , a cable winch 2 and an induction bracket 3 .

[0032] The mobile carrier 1 includes a turntable 11, a drive motor 12, and a load platform 13; the upper surface of the load platform 13 is horizontally provided with a turntable 11 driven by the drive motor 12; the bottom end of the load platform 13 is provided with hydraulic supports 14 along the vertical direction , The bottom of the loading platform 13 is provided with rollers.

[0033] The cable winch 2 comprises a winch support 21 and a rotating winch 22; the winch support 21 is arranged on the turntable 11 of the mobile carrier 1, the rotating winch 22 is installed on the winch support 21, and the rotating winch 22 is around the winch support 21 in the vertical direction Rotation; the cable winch 22 is driven by the drive motor 12 on the moving carrier 1 to drive the turntable 1...

Embodiment 2

[0042] Such as Figure 1 to Figure 6 The follow-up power supply equipment of a wharf shore power supply system shown includes a mobile carrier 1 , a cable winch 2 and an induction bracket 3 .

[0043] The mobile carrier 1 includes a turntable 11, a drive motor 12, and a load platform 13; the upper surface of the load platform 13 is horizontally provided with a turntable 11 driven by the drive motor 12; the bottom end of the load platform 13 is provided with hydraulic supports 14 along the vertical direction , The bottom of the loading platform 13 is provided with rollers.

[0044] The cable winch 2 comprises a winch support 21 and a rotating winch 22; the winch support 21 is arranged on the turntable 11 of the mobile carrier 1, the rotating winch 22 is installed on the winch support 21, and the rotating winch 22 is around the winch support 21 in the vertical direction Rotation; the cable winch 22 is driven by the drive motor 12 on the moving carrier 1 to drive the turntable 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com